SNOAA88 June 2022 LDC3114 , LDC3114-Q1

2.2.2 Test Results

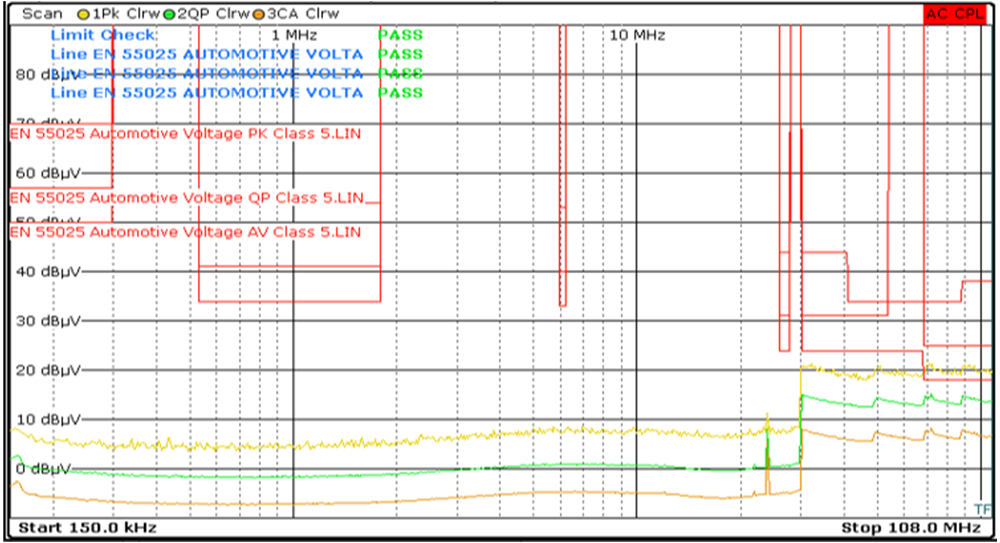

The first test done is to get a baseline of the EVM without the sensor coil included. The baseline test shown in Figure 2-11 only has the EVM with the battery connected.

Figure 2-11 Conducted Test

Baseline

Figure 2-11 Conducted Test

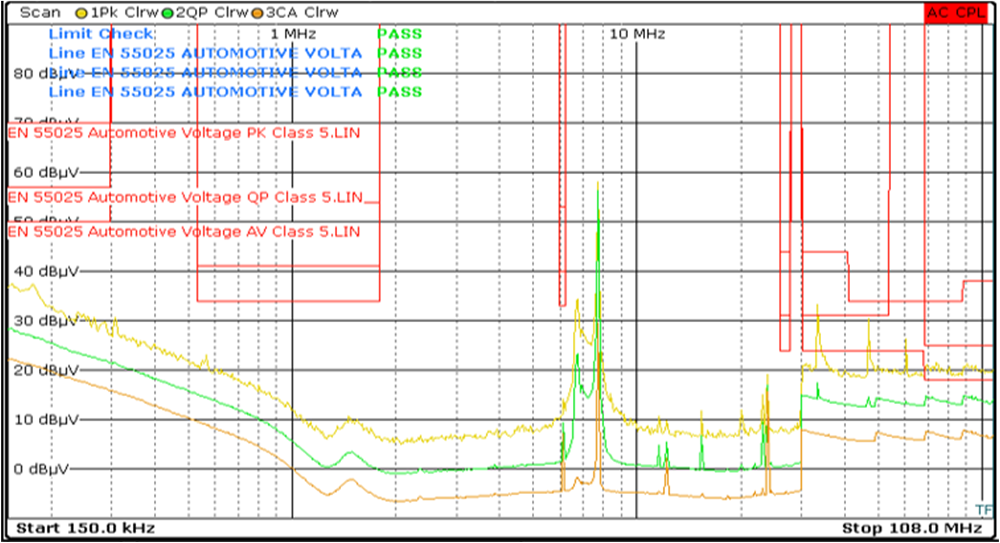

BaselineNext, a 7-MHz sensor coil is attached to the EVM and the test is run again, see the results in Figure 2-12.

Figure 2-12 Conducted Test With 7-MHz

Sensor Coil

Figure 2-12 Conducted Test With 7-MHz

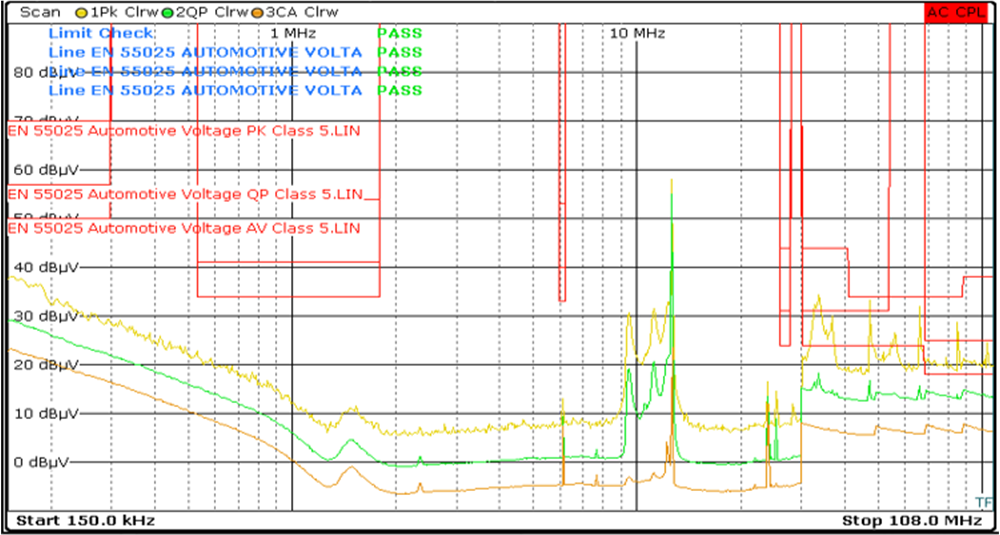

Sensor CoilThe added sensor coil has a significant impact on the test performance but the test still passes. A similar result also occurs when the coil is replaced with a 12.6-MHz coil, see Figure 2-13.

Figure 2-13 Conducted Test With 12.6-MHz

Sensor Coil

Figure 2-13 Conducted Test With 12.6-MHz

Sensor CoilThe frequency of the spikes in the test data increased as the coil frequency increased. Because of this, the coil frequency is an important part of the design when considering other EMI noise sources or any keep-out-regions for the system requirements.