SNOAA28 March 2019 TMP117

1 TI Tech Note

A heat meter is a device which measures thermal energy by measuring the flow rate and the change of temperature between the inlet and outlet of the system. These devices are very commonly found in both industrial plants to measure boiler outputs and in residential heating and cooling systems to measure the heat delivery.

Since the measurement of thermal energy requires both flow rate and temperature, it is imperative that they be measured accurately. Accuracy is important because an inaccurate measurement can result in under billing or over billing.

To avoid measurement errors, a resistance temperature detector (RTD) is commonly used. An RTD is a passive component whose resistance changes with temperature. RTDs are made using metals—such as platinum, copper, or nickel—and support a wide temperature range (approximately –200°C to +850°C). The accuracy of a Platinum RTD is defined by its class. The IEC/EN60751 standard defines four RTD classes—Class C, B, A, and AA—where Class C is the least accurate and Class AA is the most accurate. The lower accuracy classes will have a larger temperature range. For example, a Class C thin-film RTD covers the temperature range of –50°C to +600°C, while a Class AA thin-film RTD covers the temperature range of 0°C to +150°C.

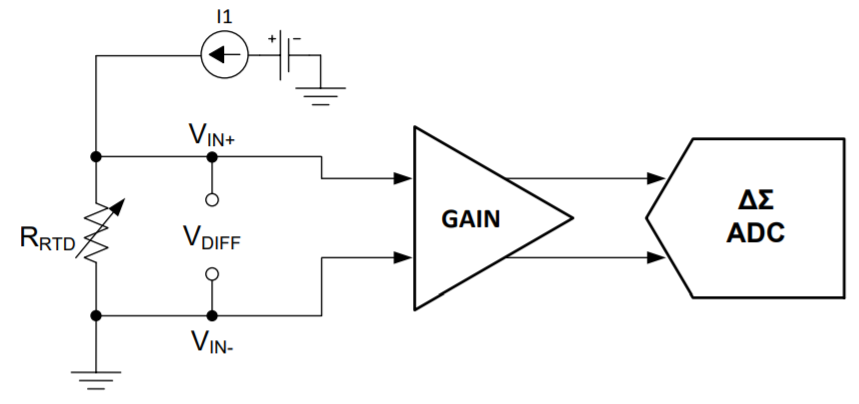

Most RTD applications use a current source to excite the RTD element and create a voltage difference across the RTD, as shown in Figure 1. This voltage is proportional to the resistance of the RTD and the excitation current. The voltage potential is amplified, converted to a digital output by an ADC, and then fed into an MCU where a lookup table is used to convert the digital output to temperature.

Figure 1. Basic RTD Circuit

Figure 1. Basic RTD Circuit SPACER

SPACER

RTDs in Heat Meters

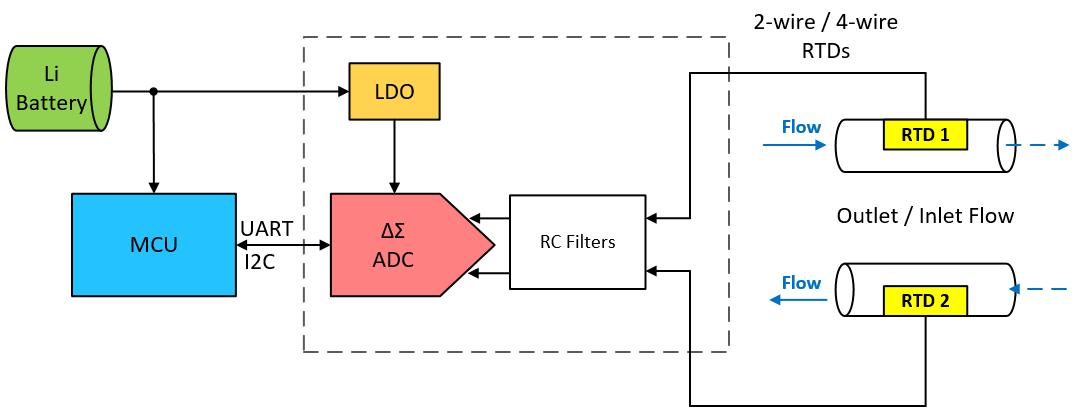

Solid-state heat meters are gaining popularity in heat energy billing for residential and industrial users. These meters come with both flow measurement on either the inlet or outlet pipe and a pair of matched RTD temperature probes on both inlet and outlet pipes. Figure 2 shows a block diagram of a heat meter system using RTDs.

Figure 2. Fluid Temperature Measurement With RTD

Figure 2. Fluid Temperature Measurement With RTD Low-power and high-accuracy RTDs in heat meters are desired because heat meters are standalone, battery-powered systems in most residential units. The system’s ability to quickly wake from power-off mode, sample the RTD temperature, and return to power-off mode extends battery life and minimized energy consumption.

However, these system require that the RTDs are well-matched and have matched traces to read the differential measurement correctly. At the same time, the system cost and complexity requires careful design consideration and costly calibration. High-accuracy digital temperature sensors like the TMP117 can provide a cost-optimized, yet equally accurate replacement for RTDs.

Replacing RTD With TMP117 Digital Temp Sensors

The TMP117 is a digital temperature sensor designed for low-power, high-accuracy applications. The device provides a 16-bit temperature result with a resolution of 0.0078°C, along with a typical factory-calibrated accuracy of ±0.1°C across –20°C to +50°C with a maximum accuracy specification of ±0.3°C over the temperature range of –55°C to +150°C, which exceeds the accuracy of a Class AA RTD in the same range.

Figure 3 illustrates the accuracy specification of the TMP117 vs an RTD. The graph clearly shows that accuracy specification for the TMP117 can easily outperform that of a Class AA RTD.

Figure 3. TMP117 vs. RTD Class-AA Accuracy

Figure 3. TMP117 vs. RTD Class-AA Accuracy The TMP117 features a shutdown mode where the device aborts the active running conversion and enters a low-power shutdown mode where it typically consumes 250 nA of current. It can perform quick, 15.5-ms temperature conversions using the one-shot conversion mode an active current as low as 3.5 μA for a duty cycle of 1 Hz. After completing a one-shot conversion, the device returns to low-power shutdown mode.

Also, the device features an offset register that automatically applies a user-defined offset to the measurement results prior to an MCU read. As the TMP117 provides additional simplicity over an RTD, it eliminates the need for costly calibration, external circuitry, matched traces, and Kelvin connections easing the system designers task for accurate measurement.

Finally the TMP117 features a fast mode (400 kHz) I2C communication. These specs make the TMP117 excellent for low-power consumption requirements, as well as quick power on-off cycling necessary in Heat Meter systems.

The TMP117, with a comparable accuracy as the Class AA thin-film RTD while consuming only a fraction of the power required for temperature measurement, is designed for a variety Heat Meter applications.

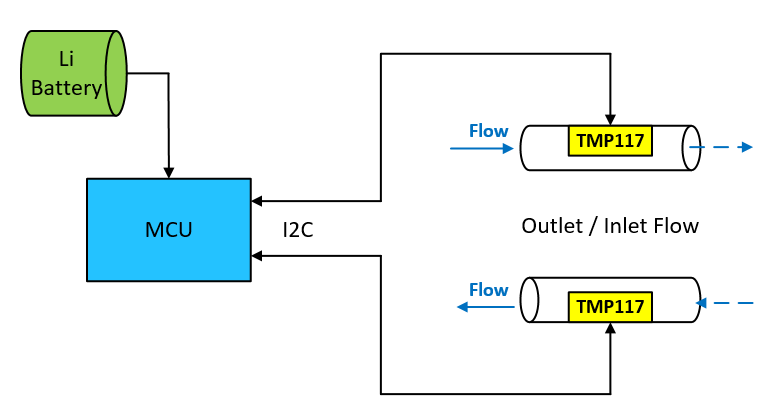

Figure 4 shows the same block diagram of Heat Meter system using the TMP117 to replace the RTDs. By using the TMP117 instead of an RTD, designers can simplify both their software and system architecture to save time, board space, and costs.

Figure 4. Fluid Temperature Measurement With TMP117

Figure 4. Fluid Temperature Measurement With TMP117 Overall, the high-accuracy TMP117 temperature sensor with digital interface, fast conversion, and extremely low-power shutdown mode eliminates the need for multiple narrow-tolerance discrete components and integrated devices, which can save PCB space, complexity, and cost in Heat Meters.

| COLLATERAL | DESCRIPTION |

| TMP117 | ±0.1°C Accurate Digital Temperature Sensor with Integrated NV Memory |

| TMP116 | ±0.2°C Accurate Digital Temperature Sensor with Integrated NV Memory |

| Application Report | RTD Class-AA Replacement With High-Accuracy Digital Temperature Sensors in Field Transmitters |

| Application Report | Replacing Resistance Temperature Detectors With the TMP116 Temp Sensor |

| Application Report | Precise Temperature Measurements with TMP116 |