DLPA129 March 2022 DLP3020-Q1 , DLP3030-Q1 , DLP5532-Q1

2 PDLC Smart Films

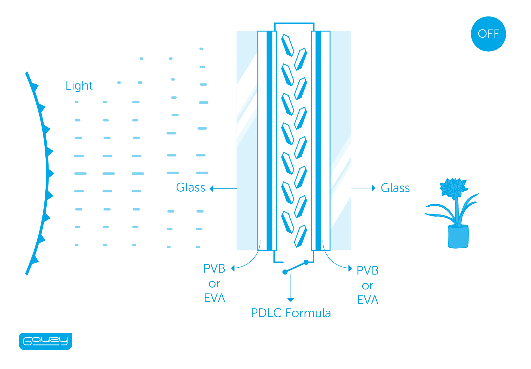

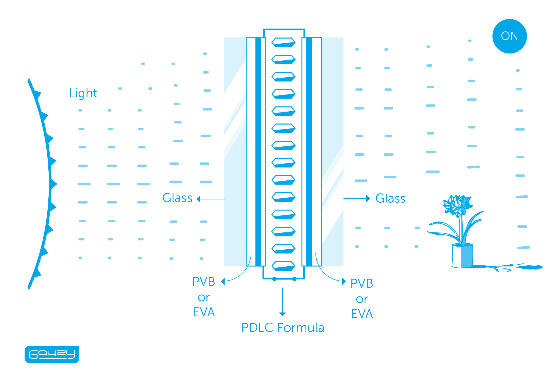

PDLC films consist of liquid crystal droplets dispersed in a UV cured optical polymer-based matrix coated between two sheets of conductive transparent layers effectively forming a capacitor. The size, characteristics, and distribution of the droplets housing the liquid crystal molecules determine the optical properties of the PDLC film. In its default state, the liquid crystals in the droplets are randomly oriented (Figure 2-1) but when a voltage of sufficient strength is applied to the capacitor, the liquid crystals align themselves to the electric field (Figure 2-2).

Figure 2-1 PDLC Film in the Off State (no

applied voltage)

Figure 2-1 PDLC Film in the Off State (no

applied voltage) Figure 2-2 PDLC Film in the On State

(+48V applied)

Figure 2-2 PDLC Film in the On State

(+48V applied)The PDLC capacitor is laminated between two pieces of glass with an adhesive interlayer of polyvinyl butyral (PVB), polyurethane (TPU), or ethylene vinyl acetate (EVA). When +48 V or greater is applied to the capacitor the film appears transparent. Power consumption of Gauzy’s PDLC film when in the transparent state is minimal at 1-4 watts per square meter depending on film shape and busbar location.

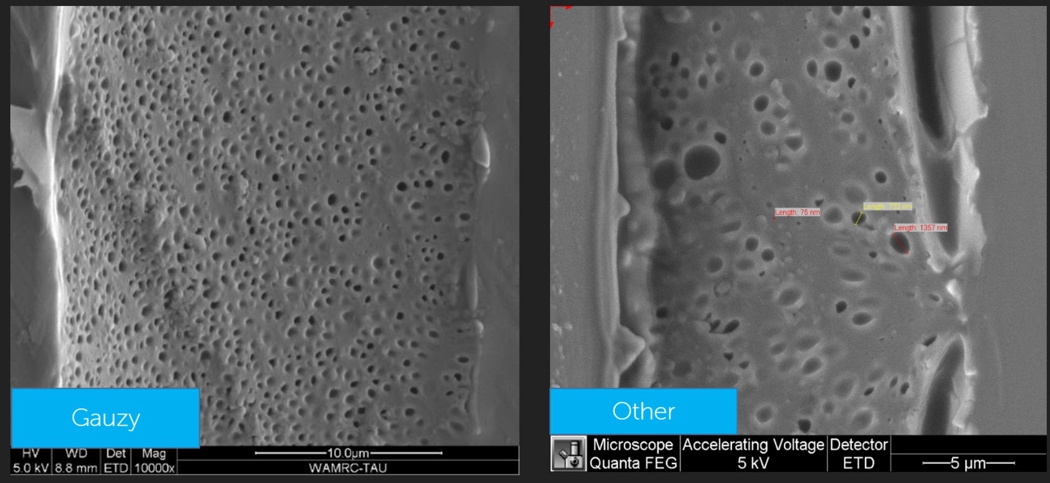

Film optical scattering properties can be manipulated through refractive index variations in the PDLC film manufacturing process. Such manipulation occurs to the different components in the formulation ultimately affecting the morphology of the film. The morphology of a PDLC film is defined based on the quantity, quality, and distribution of the liquid crystal droplets and is what determines the optical performance in both the translucent and transparent states. Figure 2-3 shows the variation in morphology and therefore optical performance between two different PDLC film suppliers.

The size and distribution of Gauzy’s droplets are distributed homogeneously to scatter light in the visible wavelength (400-700 nanometers), supporting a stable contrast ratio over a very wide viewing angle of up to 178°, making them optimized for projection screen applications.

Figure 2-3 Two Different PDLC

Morphologies. The More Consistent the Size and Distribution of the Liquid

Crystal Droplets, the Better the Optical Performance.

Figure 2-3 Two Different PDLC

Morphologies. The More Consistent the Size and Distribution of the Liquid

Crystal Droplets, the Better the Optical Performance.Gauzy PDLC films are optimized at the chemistry level to withstand automotive specifications, including stability in transparency, opacity, and switching times within -20 - +90°C temperature range, as per the requirements of automotive testing standards (PV3929). Gauzy PDLC films are likewise stabilized for automotive lamination standards which includes lamination with PVB, and can be utilized in various stack configurations with ultra-thin or multi-axis curved glazing.

Current governmental regulations allow PDLC windows to be implemented in select areas of a vehicle’s greenhouse glazing including panoramic sunroofs, or behind pillar b, the rear side passenger windows and backlights. As regulation begins to shift and the technology improves, additional vehicle window surfaces may be able to support PDLC smart glass displays.