ZHCSGU2A July 2017 – September 2017 LP5569

PRODUCTION DATA.

- 1 特性

- 2 应用

- 3 说明

- 4 修订历史记录

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

-

7 Specifications

- 7.1 Absolute Maximum Ratings

- 7.2 ESD Ratings

- 7.3 Recommended Operating Conditions

- 7.4 Thermal Information

- 7.5 Electrical Characteristics

- 7.6 Charge-Pump Electrical Characteristics

- 7.7 LED Current Sinks Electrical Characteristics

- 7.8 Logic Interface Characteristics

- 7.9 Timing Requirements (EN/PWM)

- 7.10 Serial-Bus Timing Requirements (SDA, SCL), See

- 7.11 External Clock Timing Requirements (CLK), See

- 7.12 Typical Characteristics

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3 Feature Description

- 8.4 Device Functional Modes

- 8.5 Programming

- 8.6

Register Maps

- 8.6.1

LP5569_MAP Registers

- 8.6.1.1 CONFIG Register (Address = 0h) [reset = 0h]

- 8.6.1.2 LED_ENGINE_CONTROL1 Register (Address = 1h) [reset = 0h]

- 8.6.1.3 LED_ENGINE_CONTROL2 Register (Address = 2h) [reset = 0h]

- 8.6.1.4 LED0_CONTROL Register (Address = 7h) [reset = 0h]

- 8.6.1.5 LED1_CONTROL Register (Address = 8h) [reset = 0h]

- 8.6.1.6 LED2_CONTROL Register (Address = 9h) [reset = 0h]

- 8.6.1.7 LED3_CONTROL Register (Address = Ah) [reset = 0h]

- 8.6.1.8 LED4_CONTROL Register (Address = Bh) [reset = 0h]

- 8.6.1.9 LED5_CONTROL Register (Address = Ch) [reset = 0h]

- 8.6.1.10 LED6_CONTROL Register (Address = Dh) [reset = 0h]

- 8.6.1.11 LED7_CONTROL Register (Address = Eh) [reset = 0h]

- 8.6.1.12 LED8_CONTROL Register (Address = Fh) [reset = 0h]

- 8.6.1.13 LED0_PWM Register (Address = 16h) [reset = 0h]

- 8.6.1.14 LED1_PWM Register (Address = 17h) [reset = 0h]

- 8.6.1.15 LED2_PWM Register (Address = 18h) [reset = 0h]

- 8.6.1.16 LED3_PWM Register (Address = 19h) [reset = 0h]

- 8.6.1.17 LED4_PWM Register (Address = 1Ah) [reset = 0h]

- 8.6.1.18 LED5_PWM Register (Address = 1Bh) [reset = 0h]

- 8.6.1.19 LED6_PWM Register (Address = 1Ch) [reset = 0h]

- 8.6.1.20 LED7_PWM Register (Address = 1Dh) [reset = 0h]

- 8.6.1.21 LED8_PWM Register (Address = 1Eh) [reset = 0h]

- 8.6.1.22 LED0_CURRENT Register (Address = 22h) [reset = AFh]

- 8.6.1.23 LED1_CURRENT Register (Address = 23h) [reset = AFh]

- 8.6.1.24 LED2_CURRENT Register (Address = 24h) [reset = AFh]

- 8.6.1.25 LED3_CURRENT Register (Address = 25h) [reset = AFh]

- 8.6.1.26 LED4_CURRENT Register (Address = 26h) [reset = AFh]

- 8.6.1.27 LED5_CURRENT Register (Address = 27h) [reset = AFh]

- 8.6.1.28 LED6_CURRENT Register (Address = 28h) [reset = AFh]

- 8.6.1.29 LED7_CURRENT Register (Address = 29h) [reset = AFh]

- 8.6.1.30 LED8_CURRENT Register (Address = 2Ah) [reset = AFh]

- 8.6.1.31 MISC Register (Address = 2Fh) [reset = 40h]

- 8.6.1.32 ENGINE1_PC Register (Address = 30h) [reset = 0h]

- 8.6.1.33 ENGINE2_PC Register (Address = 31h) [reset = 0h]

- 8.6.1.34 ENGINE3_PC Register (Address = 32h) [reset = 0h]

- 8.6.1.35 MISC2 Register (Address = 33h) [reset = 2h]

- 8.6.1.36 ENGINE_STATUS Register (Address = 3Ch) [reset = 80h]

- 8.6.1.37 IO_CONTROL Register (Address = 3Dh) [reset = 2h]

- 8.6.1.38 VARIABLE_D Register (Address = 3Eh) [reset = 0h]

- 8.6.1.39 RESET Register (Address = 3Fh) [reset = 0h]

- 8.6.1.40 ENGINE1_VARIABLE_A Register (Address = 42h) [reset = 0h]

- 8.6.1.41 ENGINE2_VARIABLE_A Register (Address = 43h) [reset = 0h]

- 8.6.1.42 ENGINE3_VARIABLE_A Register (Address = 44h) [reset = 0h]

- 8.6.1.43 MASTER_FADER1 Register (Address = 46h) [reset = 0h]

- 8.6.1.44 MASTER_FADER2 Register (Address = 47h) [reset = 0h]

- 8.6.1.45 MASTER_FADER3 Register (Address = 48h) [reset = 0h]

- 8.6.1.46 MASTER_FADER_PWM Register (Address = 4Ah) [reset = 0h]

- 8.6.1.47 ENGINE1_PROG_START Register (Address = 4Bh) [reset = 0h]

- 8.6.1.48 ENGINE2_PROG_START Register (Address = 4Ch) [reset = 0h]

- 8.6.1.49 ENGINE3_PROG_START Register (Address = 4Dh) [reset = 0h]

- 8.6.1.50 PROG_MEM_PAGE_SELECT Register (Address = 4Fh) [reset = 0h]

- 8.6.1.51 PROGRAM_MEM_00 Register (Address = 50h) [reset = 0h]

- 8.6.1.52 PROGRAM_MEM_01 Register (Address = 51h) [reset = 0h]

- 8.6.1.53 PROGRAM_MEM_02 Register (Address = 52h) [reset = 0h]

- 8.6.1.54 PROGRAM_MEM_03 Register (Address = 53h) [reset = 0h]

- 8.6.1.55 PROGRAM_MEM_04 Register (Address = 54h) [reset = 0h]

- 8.6.1.56 PROGRAM_MEM_05 Register (Address = 55h) [reset = 0h]

- 8.6.1.57 PROGRAM_MEM_06 Register (Address = 56h) [reset = 0h]

- 8.6.1.58 PROGRAM_MEM_07 Register (Address = 57h) [reset = 0h]

- 8.6.1.59 PROGRAM_MEM_08 Register (Address = 58h) [reset = 0h]

- 8.6.1.60 PROGRAM_MEM_09 Register (Address = 59h) [reset = 0h]

- 8.6.1.61 PROGRAM_MEM_10 Register (Address = 5Ah) [reset = 0h]

- 8.6.1.62 PROGRAM_MEM_11 Register (Address = 5Bh) [reset = 0h]

- 8.6.1.63 PROGRAM_MEM_12 Register (Address = 5Ch) [reset = 0h]

- 8.6.1.64 PROGRAM_MEM_13 Register (Address = 5Dh) [reset = 0h]

- 8.6.1.65 PROGRAM_MEM_14 Register (Address = 5Eh) [reset = 0h]

- 8.6.1.66 PROGRAM_MEM_15 Register (Address = 5Fh) [reset = 0h]

- 8.6.1.67 PROGRAM_MEM_16 Register (Address = 60h) [reset = 0h]

- 8.6.1.68 PROGRAM_MEM_17 Register (Address = 61h) [reset = 0h]

- 8.6.1.69 PROGRAM_MEM_18 Register (Address = 62h) [reset = 0h]

- 8.6.1.70 PROGRAM_MEM_19 Register (Address = 63h) [reset = 0h]

- 8.6.1.71 PROGRAM_MEM_20 Register (Address = 64h) [reset = 0h]

- 8.6.1.72 PROGRAM_MEM_21 Register (Address = 65h) [reset = 0h]

- 8.6.1.73 PROGRAM_MEM_22 Register (Address = 66h) [reset = 0h]

- 8.6.1.74 PROGRAM_MEM_23 Register (Address = 67h) [reset = 0h]

- 8.6.1.75 PROGRAM_MEM_24 Register (Address = 68h) [reset = 0h]

- 8.6.1.76 PROGRAM_MEM_25 Register (Address = 69h) [reset = 0h]

- 8.6.1.77 PROGRAM_MEM_26 Register (Address = 6Ah) [reset = 0h]

- 8.6.1.78 PROGRAM_MEM_27 Register (Address = 6Bh) [reset = 0h]

- 8.6.1.79 PROGRAM_MEM_28 Register (Address = 6Ch) [reset = 0h]

- 8.6.1.80 PROGRAM_MEM_29 Register (Address = 6Dh) [reset = 0h]

- 8.6.1.81 PROGRAM_MEM_30 Register (Address = 6Eh) [reset = 0h]

- 8.6.1.82 PROGRAM_MEM_31 Register (Address = 6Fh) [reset = 0h]

- 8.6.1.83 ENGINE1_MAPPING1 Register (Address = 70h) [reset = 0h]

- 8.6.1.84 ENGINE1_MAPPING2 Register (Address = 71h) [reset = 0h]

- 8.6.1.85 ENGINE2_MAPPING1 Register (Address = 72h) [reset = 0h]

- 8.6.1.86 ENGINE2_MAPPING2 Register (Address = 73h) [reset = 0h]

- 8.6.1.87 ENGINE3_MAPPING1 Register (Address = 74h) [reset = 0h]

- 8.6.1.88 ENGINE3_MAPPING2 Register (Address = 75h) [reset = 0h]

- 8.6.1.89 PWM_CONFIG Register (Address = 80h) [reset = 4h]

- 8.6.1.90 LED_FAULT1 Register (Address = 81h) [reset = 0h]

- 8.6.1.91 LED_FAULT2 Register (Address = 82h) [reset = 0h]

- 8.6.1.92 GENERAL_FAULT Register (Address = 83h) [reset = 4h]

- 8.6.1

LP5569_MAP Registers

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12器件和文档支持

- 13机械、封装和可订购信息

8 Detailed Description

8.1 Overview

The LP5569 device is a fully integrated lighting management unit for producing lighting effects for various LED applications. The LP5569 device includes all necessary power management, low-side current sinks, two-wire serial I2C-compatible interface, and programmable LED engines. The overall maximum current for each of the nine drivers is set with 8-bit resolution. The LP5569 device controls LED luminance with a pulse-width modulation (PWM) scheme with a resolution of 12 bits at 20 kHz, which is achieved by using 3-bit dithering.

8.1.1 Programming

The LP5569 device provides flexibility and programmability for dimming and sequencing control. Each LED can be controlled directly and independently through the serial interface, or LED drivers can be grouped together for preprogrammed flashing patterns. The device has three independent program execution engines. Each engine can control 1 to 9 LED driver outputs, but more than one engine cannot simultaneously control the same LED driver output. Any engine can be used as the master fader for all three engines.

8.1.2 Energy Efficiency

An integrated 1× or 1.5× charge pump with adaptive control provides supply voltage for LEDs when operating with low input voltage. Because the LED drivers are low-side sinks, some or all LEDs can be powered from an external source if available. The LP5569 device has very low standby current and an automatic power-save mode when the LEDs are inactive.

8.1.3 Protection Features

Protection features include power-on reset, charge-pump input-current limiter, thermal shutdown (TSD), and undervoltage lockout (UVLO).

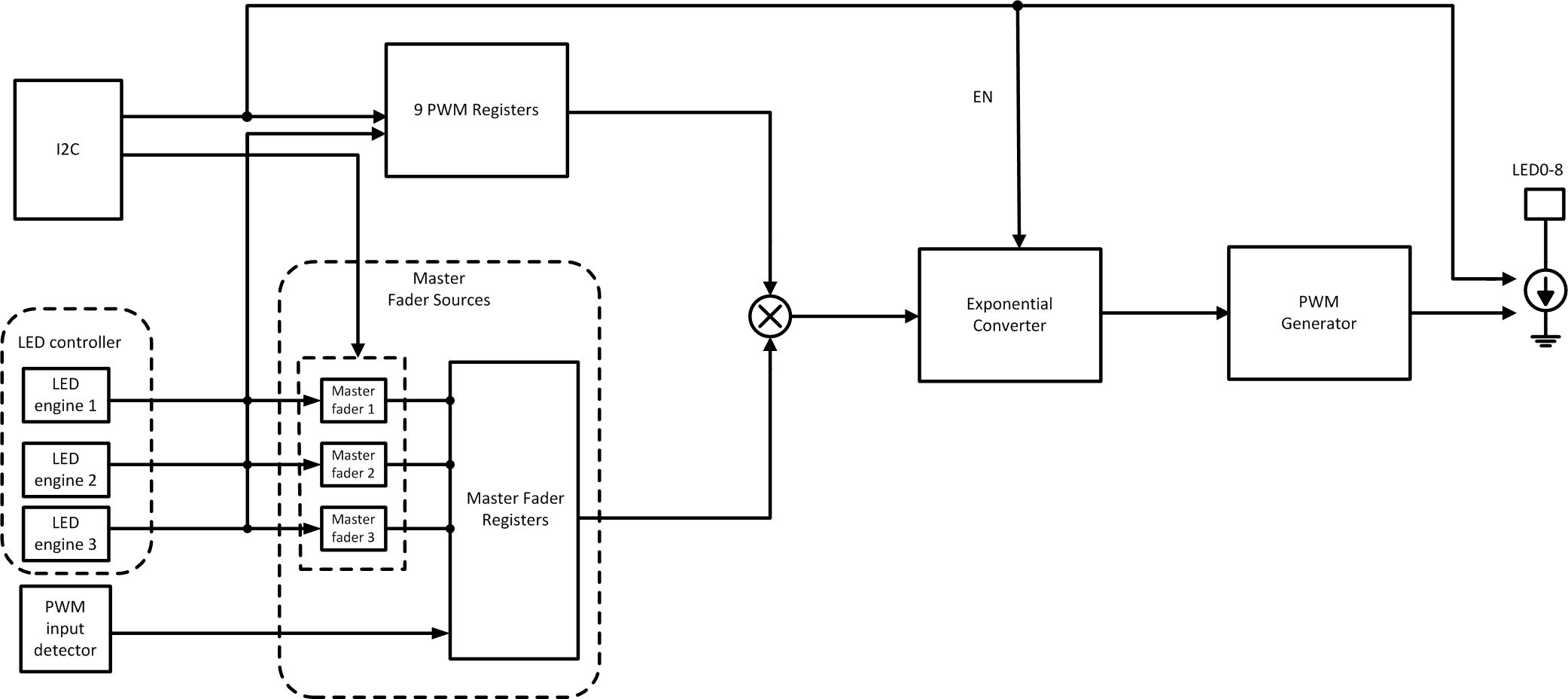

8.2 Functional Block Diagram

8.3 Feature Description

8.3.1 Current Sinks

8.3.1.1 Overview

The LP5569 LED drivers are constant-current sources. Maximum output-current scale can be programmed by control registers up to 25.5 mA. The overall maximum current is set by 8-bit output current-control registers with 100-μA step size. Each of the 9 LED drivers has a separate output-current control register. The LED luminance pattern (dimming) is controlled with a PWM technique, which has 12-bit resolution during ramping and 8-bit user control. The LED current-sink PWM frequency is 20 kHz.

High 20-kHz PWM frequency and 12-bit control accuracy are achieved by using 3-bit dithering for PWM control. There is a 9-bit pure PWM resolution generated in the PWM generators, and one least-significant bit (1 LSB) is toggled in eight periods to output a smaller average step. For 3-bit dithering, every eighth pulse is made 1 LSB longer to increase the average value by 1 / 8th. Figure 12 shows an example of 9-bit PWM value, step of 4 / 8 (0.5) and its 12-bit representation.

Figure 12. Dithering

Figure 12. Dithering

A phase-shift PWM scheme allows delaying the time when each LED driver is active. When the LED drivers are not activated simultaneously, the peak load current from the charge-pump output is greatly decreased. This also reduces input-current ripple and ceramic-capacitor audible ringing. LED drivers are grouped into three different phases. In phase 1, the rising edge of the PWM pulse is fixed in time. In phase 2, the middle point of the PWM pulse is fixed, and the pulse spreads to both directions when PWM duty cycle is increased. Phase 3 has a fixed falling edge, that is, the rising edge of the pulse is changed when the duty cycle changes.

Figure 13. LED Phase Shift

Figure 13. LED Phase Shift

LED dimming is controlled according to an exponential or linear scale (see Figure 14) In exponential mode, the PWM output percent can be approximated by the following two equations:

- Less than or equal to code 64: y = 0.0125x – 0.0066.

- Greater than code 64: y = 0.7835e0.0217x

Figure 14. 8-Bit User PWM Control, Exponential and Linear Dimming

Figure 14. 8-Bit User PWM Control, Exponential and Linear Dimming

8.3.1.2 Controlling the Low-Side Current Sinks

8.3.1.2.1 Direct Register Control

All LP5569 LED drivers, LED0 to LED8, can be controlled independently through the two-wire serial I2C-compatible interface. For each low-side driver there is an 8-bit PWM control register which can be used to control the LED PWM duty-cycle value. This register cannot be written when the program execution engine is active, which could result in undesirable behavior. Care should be taken to update these registers only when the program execution engine is idle.

8.3.1.2.2 Controlling by Program Execution Engines

Engine control is used when the user wants to create programmed sequences. The program execution engine updates the direct-control registers when active. Therefore, if the user has set the PWM register to a certain value, it is automatically overridden when the program execution engine controls the driver. LED control and program-execution-engine operation is described in Programming.

8.3.1.2.3 Master Fader Control

In addition to LED-by-LED PWM register control, the LP5569 device is equipped with a master-fader control, which allows the user to fade in or fade out multiple LEDs from the EN/PWM pin or by writing to the master fader registers. This is a useful function to minimize serial bus traffic between the MCU and the LP5569 device. The LP5569 device has three master fader registers, so it is possible to form three master fader groups. Either writing master fader registers through the I2C interface directly or through LED engine control can set the master fader register values. The final output PWM duty cycle is the PWM register duty-cycle value multiplied by the duty-cycle value of the master fader register.

Figure 15. Simplified Data Flow of Master Fader

Figure 15. Simplified Data Flow of Master Fader

8.3.1.2.3.1 PWM Master Fader on EN/PWM Pin

The EN/PWM pin provides a dual-function input. On power up, the pin functions as the device enable (EN) function, where the first rising edge enables the LP5569 device. After the chip_en bit is set high in the CONFIG register, the pin is reconfigured for PWM master-fader control of the LEDs. The LEDx_CONTROL register (addresses 07h–0Fh) MF_MAPPINGx bits = 5h configures LEDx for PWM control.

The PWM input is a sampled input which converts the input duty-cycle information into an 11-bit code. The use of a sampled input eliminates any noise and current ripple that is typical of traditional PWM-controlled LED drivers. The PWM input uses logic-level thresholds with VIH_MIN = 1.25 V and VIL_MAX = 0.4 V. Because this is a sampled input, there are limits on the maximum PWM input frequency as well as the resolution that can be achieved.

8.3.1.2.3.2 PWM Master Fader Resolution and Input Frequency Range

The PWM input frequency range is 100 Hz to 20 kHz. To achieve the full 11-bit maximum resolution of PWM duty cycle to the code, the input PWM duty cycle must be ≥ 11 bits, and the PWM sample period (1 / fSAMPLE) must be smaller than the minimum PWM input pulse duration. Figure 16 shows the possible brightness code resolutions based on the input PWM frequency.

Figure 16. PWM Resolution vs PWM Input Frequency

Figure 16. PWM Resolution vs PWM Input Frequency

8.3.1.2.3.3 PWM Master Fader Hysteresis

To prevent jitter on the input PWM signal from feeding through the PWM path and causing oscillations in the LED current, the LP5569 device offers seven selectable hysteresis settings. The hysteresis works by forcing a specific number of 11-bit LSB code transitions to occur in the input duty cycle before the LED current changes. Table 1 describes the hysteresis. The hysteresis only applies during a change in direction of brightness currents. Once the change in direction has taken place, the PWM input must overcome the required LSB(s) of the hysteresis setting before the brightness change takes effect. Once the initial hysteresis has been overcome and the direction in brightness change remains the same, the PWM-to-current response changes with no hysteresis.

Table 1. PWM Input Hysteresis

| HYSTERESIS SETTING (0x80 bits [2:0]) |

MIN. CHANGE IN PWM PULSE DURATION (Δt) REQUIRED TO CHANGE LED CURRENT, AFTER DIRECTION CHANGE (for fPWM < 11.7 kHz) |

MIN. CHANGE IN PWM DUTY CYCLE (ΔD) REQUIRED TO CHANGE LED CURRENT AFTER DIRECTION CHANGE | MIN (ΔILED), INCREASE FOR INITIAL CODE | |

|---|---|---|---|---|

| EXPONENTIAL MODE | LINEAR MODE | |||

| 000 (0 LSB) | 1 / (fPWM × 2047) | 0.05% | 0.3% | 0.05% |

| 001 (1 LSB) | 1 / (f PWM× 1023) | 0.1% | 0.61% | 0.1% |

| 010 (2 LSB) | 1 / (fPWM × 511) | 0.2% | 1.21% | 0.2% |

| 011 (3 LSB) | 1 / (fPWM × 255) | 0.39% | 2.4% | 0.39% |

| 100 (4 LSB) | 1 / (fPWM × 127) | 0.78% | 4.74% | 0.78% |

| 101 (5 LSB) | 1 / (fPWM × 63) | 1.56% | 9.26% | 1.56% |

| 110 (6 LSB) | 1 / (fPWM × 31) | 3.12% | 17.66% | 3.12% |

Figure 17. PWM Hysteresis Example

Figure 17. PWM Hysteresis Example

8.3.1.2.4 EN/PWM Input Timeout

The EN/PWM input timeout feature has two operating modes as follows:

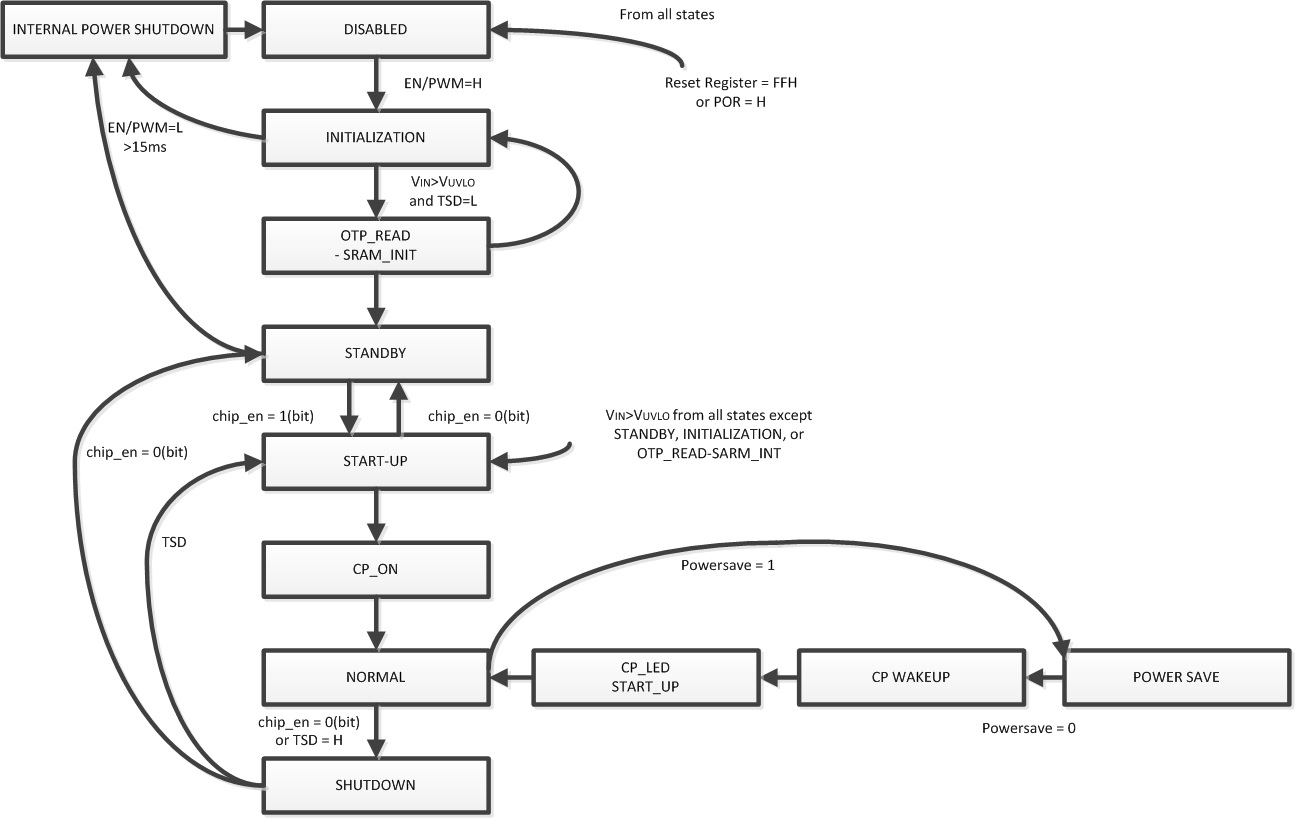

- STANDBY state: EN/PWM low for > 15 ms shuts down the LP5569 device and returns to the DISABLED state (see Figure 20).

8.3.2 Charge Pump

8.3.2.1 Overview

The LP5569 device includes a pre-regulated switched-capacitor charge pump with a programmable voltage multiplication of 1× or 1.5×. In 1.5× mode, by combining the principles of a switched-capacitor charge pump and a linear regulator, a regulated 4.5-V output is generated from the VIN input within its normal voltage range. A two-phase non-overlapping clock, generated internally, controls the operation of the charge pump. During the charge phase, both flying capacitors (CFLY1 and CFLY2) are charged from input voltage. In the pump phase that follows, the flying capacitors are discharged to the output. A traditional switched-capacitor charge pump operating in this manner uses switches with very low on-resistance, ideally 0 Ω, to generate an output voltage that is 1.5× the input voltage. The LP5569 device regulates the output voltage by controlling the resistance of the input-connected pass-transistor switches in the charge pump.

8.3.2.2 Pre-Regulation

The very low input-current ripple of the LP5569 device, resulting from internal pre-regulation, adds minimal noise to the input line. The core of the LP5569 device is very similar to that of a basic switched-capacitor charge pump: it is composed of switches and two flying capacitors (external). Regulation is achieved by controlling the current through the switches connected to the VIN pin (one switch in each phase). The regulation occurs before the voltage multiplication, giving rise to the term pre-regulation. It is pre-regulation that eliminates most of the input-current ripple that is a typical and undesirable characteristic of a many switched-capacitor converters.

8.3.2.3 Input Current Limit

The LP5569 device contains current-limit circuitry that protects the device in the event of excessive input current and/or output shorts to ground. The input current is limited to 600 mA (typical) when the output is shorted directly to ground. When the LP5569 device is current limiting, power dissipation in the device is likely to be quite high. In this event, thermal cycling should be expected.

8.3.2.4 Output Discharge

The LP5569 device provides a feature to discharge the charge-pump output capacitor. The charge-pump output pulldown is not enabled when the MISC2 register (address 33h) CP_DIS_DISCH bit = 1. The charge pump output pulldown is enabled when the CP_DIS_DISCH bit = 0. The pulldown draws a minimal current from the output capacitor (300 μA typical) when in the SHUTDOWN and STANDBY states.

8.3.2.5 Controlling the Charge Pump

The charge pump is controlled with two CP_MODE bits in the MISC register (address 2Fh). When both of the bits are low, the charge pump is disabled, and output voltage is pulled down as described in Output Discharge. The charge pump can be forced to the bypass mode, so the battery voltage is connected directly to the current source; in 1.5× mode the output voltage is boosted to 4.5 V. In automatic mode, the charge-pump operation mode is determined by saturation of the constant-current drivers described in LED Forward Voltage Monitoring.

8.3.2.6 LED Forward Voltage Monitoring

When the charge-pump automatic-mode selection is enabled, voltages on the LED current sinks LED0 to LED8 are monitored. If the current sinks do not have enough headroom, the charge pump gain is set to 1.5× and remains in 1.5× mode until one of the following occurs:

- The LP5569 device enters the SHUTDOWN state and goes through the INITIALIZATION or STARTUP state.

- The charge-pump mode is forced to 1× mode via the MISC register.

- The LP5569 device exits power save when the charge pump is in automatic mode (CP_MODE bits = 3h).

Figure 18. Forward-Voltage-Monitoring and Gain-Control Block

Figure 18. Forward-Voltage-Monitoring and Gain-Control Block

8.3.3 Energy Efficiency

8.3.3.1 LED Powering

The red LED (R) element of an RGB LED typically has a forward voltage of about 2 V. These LEDs can be powered directly from the input voltage because battery voltage is typically high enough to drive red LEDs over the whole operating voltage range. This allows driving of three RGB LEDs with good efficiency because the red LEDs do not load the charge pump. When the LEDx_CONTROL (address 07h–0Fh) register EXTERNAL_POWERx bit = 1, the LEDx output is configured for external supply, and forward-voltage monitoring is disabled.

8.3.4 Automatic Power-Save Mode

When the LED outputs are not active, the LP5569 device is able to enter the power-save mode automatically, thus lowering idle-current consumption down to 10 μA (typical). Automatic power-save mode is enabled when the MISC register (address 2Fh) POWERSAVE_EN bit = 1. Almost all analog blocks are powered down in power save, if an external clock signal is used. The charge pump enters the weak 1× mode using a passive current-limited keep-alive switch, which keeps the output voltage at the battery level to reduce output-voltage transients.

During program execution, the LP5569 device can enter power save if there is no PWM activity in any of the LED driver outputs. To prevent short power-save sequences during program execution, the device has an instruction look-ahead filter. In power-save mode, program execution continues without interruption. When an instruction that requires PWM activity is executed, a fast internal start-up sequence is started automatically.

8.3.5 Protection Features

8.3.5.1 Thermal Shutdown (TSD)

The LP5569 device implements a thermal shutdown mechanism to protect the device from damage due to overheating. When the junction temperature rises to 150°C (typical), the device switches into shutdown mode. The LP5569 device releases thermal shutdown when the junction temperature of the device decreases to 130°C (typical).

Thermal shutdown is most often triggered by self-heating, which occurs when there is excessive power dissipation in the device and/or insufficient thermal dissipation. LP5569 power dissipation increases with increased output current and input voltage. When self-heating brings on thermal shutdown, thermal cycling is the typical result. Thermal cycling is the repeating process where the part self-heats, enters thermal shutdown (where internal power dissipation is practically zero), cools, turns on, and then heats up again to the thermal shutdown threshold. Thermal cycling is recognized by a pulsing output voltage and can be stopped by reducing the internal power dissipation (reduce input voltage and/or output current) or the ambient temperature. If thermal cycling occurs under desired operating conditions, thermal dissipation performance must be improved to accommodate the power dissipation of the LP5569 device. The QFN package is designed to have excellent thermal properties that, when soldered to a PCB designed to aid thermal dissipation, allows the LP5569 device to operate under very demanding power-dissipation conditions.

8.3.5.2 Undervoltage Lockout (UVLO)

The LP5569 device has an internal comparator that monitors the voltage at VIN. If the input voltage drops to 2.2 V (nominal), undervoltage is detected, the LED outputs and the charge pump shut down, and the corresponding fault bit is set in the fault register. Hysteresis is implemented for the threshold level to avoid continuous triggering of a fault when the threshold is reached. If the input voltage rises above 2.3 V (nominal), the LP5569 device resumes normal operation.

8.3.5.3 Power-On Reset (POR)

The LP5569 device has internal comparators that monitor the voltages at VIN and V1P8. When VVIN is below 2.2 V or V1P8 is below 1.3 V, reset is active and the LP5569 device is in the DISABLED state.

8.3.5.4 LED Fault Detection

The LP5569 device contains both open-LED and shorted-LED fault detection. These fault detections are designed to be used in production-level testing and not normal operation. For the fault flags to operate, they must be enabled via the MISC2 register (address 33h) LED_OPEN_TEST and LED_SHORT_TEST bits. The fault flags are shared by both open-LED and shorted-LED tests so only one can be enabled at a time. The default LED-fault status is ready in the LED_FAULT1 and LED_FAULT2 registers (addresses 81h and 82h). The following sections detail the proper procedure for reading back open and short faults in the LED strings.

8.3.5.4.1 Open LED

The LP5569 device features one fault flag per LED, indicating one or more of the active low-voltage LED strings are open. An open in a low-voltage LED string is flagged if the voltage at the input to any active low-voltage current sink goes below the drv_headroom[1:0] setting in the MISC2 register. The procedure for detecting an open-LED fault is:

- Set the LP5569 device in the STANDBY state.

- Configure the charge pump in the 1.5× mode.

- Set the LED_OPEN_TEST bit = 1 in the MISC2 register (address 33h).

- Set the chip_en bit = 1 in the CONTROL register (address 0h) with the LP5569 device in the NORMAL state.

- Wait at least 500 µs.

- Enable all LEDs, and set all LEDs to 100% brightness.

- Wait at least 500 µs.

- Check the fault status of the LED_FAULT1 and LED_FAULT2 registers.

- Set the LED_OPEN_TEST bit = 0 in the MISC2 register (address 33h).

- Set all LEDs to 0% brightness.

8.3.5.4.2 Shorted LED

The LP5569 device features one fault flag per LED, indicating when any active LED is shorted (anode to cathode). During the LED short test, the charge pump is forced to the 1× mode. A short in the LED is determined when the LED voltage (VIN –V LEDx) falls below 1 V. The procedure for detecting a shorted-LED fault is:

- Set the LP5569 device in the STANDBY state.

- Configure the charge pump in the 1× mode, set LED PWM (0x16–0x1E) and LED current (0x22–0x2A) to maximum value, depending on the LED channel being tested.

- Set the chip_en bit in the CONFIG register = 1 and the LP5569 device to the NORMAL state.

- Wait at least 500 µs.

- Enable all LEDs, and set brightness to 100%.

- Set the LED_SHORT_TEST bit = 1 in the MISC2 register (address 33h).

- Wait at least 500 µs.

- Check the fault status of the LED Fault1 and LED Fault2 registers.

- Set the LED_SHORT_TEST bit = 0 in in the MISC2 register (address 33h).

- Set all LEDs to 0% brightness.

8.3.6 Clock Generation and Synchronization

The LP5569 device can generate a 32-kHz clock signal and use it for synchronizing multiple devices. The CLK pin is configured as an input by default. When the EN_CLK_OUT bit = 1 in the IO_CONTROL register (address 3Dh) the LP5569 device drives the CLK pin using its 32-kHz oscillator.

Figure 19. Synchronizing Multiple Devices Using the Clock Generator

Figure 19. Synchronizing Multiple Devices Using the Clock Generator

8.3.7 GPIO/TRIG/INT Multifunctional I/O

The GPIO/TRIG/INT pin is configured by the GPIO_CONFIG bits in the IO_CONTROL register (address 3Dh). The default configuration for this pin is the INT function.

8.4 Device Functional Modes

8.4.1 Modes Of Operation

-

CP_LED_STARTUP: LED drivers are enabled. The device enters NORMAL after 300 µs (typical).

-

CP_ON: Charge pump is enabled per CP_MODE bits, and charge-pump output voltage is within regulation after 300 µs (typical).

-

CP_WAKEUP After the power-save condition is no longer met, the device enters the CP_WAKEUP state. The device enters CP_LED_STARTUP after 100 µs (typical).

-

DISABLED:The device enters this state when logic receives POR or the EN/PWM pin is low for longer than 15 ms (typical). The internal logic is disabled in this state to minimize power consumption. The mode changes to INITIALIZATION when a rising edge has been detected in the EN/PWM pin and TSD is inactive.

-

INITIALIZATION:This state duration is 2 ms (typical). The device enters the OTP_READ–SRAM_INIT state if VVIN is above the VUVLO level, and the temperature is below TSD. If VVIN is below VUVLO or TSD is active, the device remains in INITIALIZATION unless EN/PWM is low for 15 ms (typical), then the device enters the DISABLED mode.

-

INTERNAL POWER SHUTDOWN:In INTERNAL POWER SHUTDOWN mode, the internal LDO is shutdown.

-

NORMAL:After startup has been completed the device enters the NORMAL mode. Users can drive LEDs and execute programs in this mode.

-

OTP_READ - SRAM_INIT: The OTP_READ mode is followed by SRAM_INIT, which initializes SRAM. When initialization is complete, the device enters the STANDBY state. If VIN is below VUVLO while in this state, the device returns to INITIALIZATION.

-

POWER SAVE:In POWER SAVE mode, analog blocks are disabled to minimize power consumption. After the power-save condition is no longer met, the device exits the POWER SAVE mode. See Automatic Power-Save Mode section for further information.

-

SHUTDOWN:During shutdown, the charge-pump and LED drivers are disabled. The device enters the shutdown state if disabled (chip_en = 0) or if a TSD fault is active. The device enters STANDBY after 1 ms (typical).

-

STANDBY:The STANDBY mode is a low-power-consumption mode and is entered if the register bit chip_en is zero and Reset is not active. Register and SRAM access is available via I2C.

-

START-UP: During a fault condition, device operation is halted, and the device waits in STARTUP mode until no faults are present. UVLO detection returns the device to STARTUP from all states with the exception of STANDBY, INITIALIZATION, and OTP_READ - SRAM_INIT.

Figure 20. LP5569 Function State Machine

Figure 20. LP5569 Function State Machine

8.5 Programming

8.5.1 I2C Interface

The I2C-compatible two-wire serial interface provides access to the programmable functions and registers on the device. This protocol uses a two-wire interface for bidirectional communications between the devices connected to the bus. The two interface lines are the serial data line (SDA) and the serial clock line (SCL). Every device on the bus is assigned a unique address and acts as either a master or a slave depending on whether it generates or receives the serial clock, SCL. The SCL and SDA lines should each have a pullup resistor placed somewhere on the line and remain HIGH even when the bus is idle. Note: the CLK pin is not used for serial bus data transfer.

8.5.1.1 Data Validity

The data on SDA line must be stable during the HIGH period of the clock signal (SCL). In other words, state of the data line can only be changed when clock signal is LOW.

Figure 21. Data Validity Diagram

Figure 21. Data Validity Diagram

8.5.1.2 Start and Stop Conditions

START and STOP conditions classify the beginning and the end of the data transfer session. A START condition is defined as the SDA signal transitioning from HIGH to LOW while SCL line is HIGH. A STOP condition is defined as the SDA transitioning from LOW to HIGH while SCL is HIGH. The bus master always generates START and STOP conditions. The bus is considered to be busy after a START condition and free after a STOP condition. During data transmission, the bus master can generate repeated START conditions. First START and repeated START conditions are functionally equivalent.

8.5.1.3 Transferring Data

Every byte put on the SDA line must be eight bits long, with the most significant bit (MSB) being transferred first. Each byte of data must be followed by an acknowledge bit. The acknowledge-related clock pulse is generated by the master. The master releases the SDA line (HIGH) during the acknowledge clock pulse. The LP5569 device pulls down the SDA line during the ninth clock pulse, signifying an acknowledge. The LP5569 device generates an acknowledge after each byte has been received.

There is one exception to the acknowledge after every byte rule. When the master is the receiver, it must indicate to the transmitter an end of data by not-acknowledging (negative acknowledge) the last byte clocked out of the slave. This negative acknowledge still includes the acknowledge clock pulse (generated by the master), but the SDA line is not pulled down.

After the START condition, the bus master sends a device address. This address is seven bits long followed by an eighth bit which is a data direction bit (READ or WRITE). For the eighth bit, a 0 indicates a WRITE, and a 1 indicates a READ. The second byte selects the register to which the data is to be written. The third byte contains data to write to the selected register.

8.5.1.4 I2C Slave Addressing

The LP5569 slave address is defined by connecting GND, SCL, SDA, or VIN to the ADDR pin. A total of four slave addresses can be realized by combinations when GND, SCL, SDA, or VIN is connected to the ADDR pin (see Table 2).

The LP5569 device is available in two versions (LP5569 and LP5569A). Each version has four possible address settings, which allows up to eight devices sharing the same I2C bus as shown in Table 2. Values are in 7-bit slave ID format. The LP5569 device responds to slave address 40h regardless of the setting of the ADDR pin and device version. Global writes to address 40h can be used for configuring all devices simultaneously. The LP5569 device supports global read using slave address 40h; however, the data read is only valid if all LP5569 devices on the I2C bus contain the same value in the register read.

Table 2. LP5569 Slave-Address Combinations

| SLAVE ID | VERSION | ADDR |

| 32h and 40h | GND | |

| 33h and 40h | SCL | |

| 34h and 40h | SDA | |

| 35h and 40h | VIN | |

| 42h and 40h | A | GND |

| 43h and 40h | A | SCL |

| 44h and 40h | A | SDA |

| 45h and 40h | A | VIN |

Figure 22. LP5569 Chip Address

Figure 22. LP5569 Chip Address

8.5.1.5 Control Register Write Cycle

- The master device generates a start condition.

- The master device sends the slave address (7 bits) and the data direction bit (R/W = 0).

- The slave device sends an acknowledge signal if the slave address is correct.

- The master device sends the control register address (8 bits).

- The slave device sends an acknowledge signal.

- The master device sends the data byte to be written to the addressed register.

- The slave device sends an acknowledge signal.

- If the master device sends further data bytes, the control register address of the slave is incremented by 1 after the acknowledge signal. In order to reduce program load time, the LP5569 device supports address auto incrementation. The register address is incremented after each 8 data bits. For example, the whole program memory page can be written in one serial-bus write sequence.

- The write cycle ends when the master device creates a stop condition.

Figure 23. Write Cycle (W = Write; SDA = 0)

Figure 23. Write Cycle (W = Write; SDA = 0)

8.5.1.6 Control Register Read Cycle

- The master device generates a start condition.

- The master device sends the slave address (7 bits) and the data direction bit (R/W = 0).

- The slave device sends an acknowledge signal if the slave address is correct.

- The master device sends the control register address (8 bits).

- The slave device sends an acknowledge signal.

- The master device generates a repeated-start condition.

- The master device sends the slave address (7 bits) and the data direction bit (R/W = 1).

- The slave device sends an acknowledge signal if the slave address is correct.

- The slave device sends the data byte from the addressed register.

- If the master device sends an acknowledge signal, the control register address is incremented by 1. The slave device sends the data byte from the addressed register.

- The read cycle ends when the master device does not generate an acknowledge signal after a data byte and generates a stop condition.

8.5.1.7 Auto-Increment Feature

The auto-increment feature allows writing several consecutive registers within one transmission. Every time an 8‑bit word is sent to the LP5569 device, the internal address index counter is incremented by 1, and the next register is written. The auto-increment feature is enabled by default and can be disabled by setting the EN_AUTO_INCR bit = 0 in the MISC register (address 2Fh).

8.5.2 Execution Engine Programming

The LP5569 device provides flexibility and programmability for dimming and sequencing control. Each LED can be controlled directly and independently through the serial bus, or LED drivers can be grouped together for pre-programmed flashing patterns.

The LP5569 device has three independent program execution engines, so it is possible to form three independently programmable LED banks. LED drivers can be grouped based on their function so that, for example, the first bank of drivers can be assigned to the keypad illumination, the second bank to the funlights, and the third group to the indicator LED(s). Each bank can contain 1 to 9 LED driver outputs. Instructions for program execution engines are stored in the program memory. The total amount of the program memory is 255 instructions, and the user can allocate the instructions as required by the engines; however, a single engine can only allocate up to ½ the memory (128 instructions).

8.5.2.1 SRAM Memory

The LP5569 device has internal SRAM for the three LED engines. SRAM can contain up to 255 16-bit instructions (addresses 0 through 254) with a maximum size of 128 16-bit instructions for a single engine. SRAM memory address 255 is reserved and must not be allocated to any LED engine. Memory allocation among the three LED engines is done dynamically, so that each LED engine has a separate start address and program counter (PC) that are set in the ENGINEx_PROG_START registers (addresses 4Bh, 4Ch, 4Dh) and ENGINEx_PC registers (addresses 30h, 31h, 32h). This allows flexible memory allocation among the LED engines, and multiple engines can recall the same memory address. The program counter uses relative memory addressing; when the PC is zero the engine is executing an instruction at its start address.

The SRAM is loaded via the I2C interface in 33-byte-length pages. The first byte contains the program-memory-page-select (address 4Fh) followed by up to 32 bytes containing compiled program execution engine instructions (address 50h thru 6Fh). Engines must be set to load the program mode (register 01h) before writing the SRAM.

8.5.2.2 Variables

The LP5569 device has four LED engine variables which are divided into local and global variables. Variables A and B are engine-specific local variables and each of the three engines has separate A and B variables, so there is a total of six A and B variables. Variable A can be read and written via I2C registers 42h–44h. Local variable B is not available via I2C and can only be accessed by the LED engine. Variables C and D are global variables which are shared by all three LED engines. Global variable C is not available via I2C and can only be accessed by the LED engines. The D variable can be read and written via I2C register 3Eh. Variables are referenced to instructions with 2 bits, see Table 3 for details. Note that some instructions (ld, add, sub) can use only variables A, B, and C as target variables.

Table 3. LED Engine Variables

| VARIABLE | BITS | LOCAL/GLOBAL |

| A | 00 | Local |

| B | 01 | Local |

| C | 10 | Global |

| D | 11 | Global |

8.5.2.3 Instruction Set

The LP5569 device has three independent programmable execution engines. All the program execution engines have their own program memory block allocated by the user. The maximum program size for any one engine is limited to 128 locations. At least one engine must be in the load-program mode with the engine-busy bit cleared before writing to any program memory address. Program execution is clocked with a 32.768-kHz clock. Instruction execution takes sixteen clock cycles (488 μs). This applies also to ramp and wait instructions where execution time is a multiple of 488 μs. This clock can be generated internally or an external clock can be supplied to the CLK pin. Using an external clock enables synchronization of LED timing to the external clock signal and is also more power-efficient. The supported instruction set is listed in Table 4 through Table 6. The LP5569 device is fully compatible with the LP5523 instruction set. A command compiler is available for easy sequence programming. With the command compiler it is possible to write sequences with simple ASCII commands, which are then converted to binary or hex format.

Table 4. LED Driver Instructions

| INSTRUCTION | USAGE | COMPILER EXAMPLE |

| ramp(1) | Generate a programmable PWM ramp to mapped LED driver(s) from the current value to a new value in steps of +1 or –1 with programmed step time. | ramp 0.6, 255; ramp to full scale in 0.6 s |

| ramp(2) | ramp var1, prescale, var2 var1 is a variable (ra, rb, rc, rd); prescale is a boolean constant (pre = 0 or pre = 1); Var2 is a variable (ra, rb, rc, rd). Output PWM with increasing or decreasing duty cycle. | ld ra, 31 ld rb, 255 ramp ra, pre=0, +rb; ramp up to full scale over 3.9 s. |

| set_pwm(1) | Set PWM or current value to mapped LED driver(s), effective immediately. | set_pwm 128; set duty cycle to 50%. |

| set_pwm(2) | set_pwm var1 Var1 is a variable (ra, rb, rc, rd). Generate a continuous PWM output. | ld rc, 128; set_pwm rc; set PWM duty cycle to 50%. |

| wait | Wait for a given time. Time span is from 0.488 ms to 484 ms. | wait 0.4; wait for 0.4 s; wait for 0.4 s |

Table 5. LED Mapping Instructions

| INSTRUCTION(1) | ACT(2) | USAGE | COMPILER EXAMPLE |

| load_start | Define the LED mapping-table start address in SRAM. | load_start 01h; starting address at 01h | |

| map_start | x | Define the LED mapping-table start address in SRAM and set that address active. | map_start 01h; starting address at 01h |

| load_end | Define the last address of the LED mapping table in SRAM. | load_end 03h; last address at 03h | |

| map_sel | x | Connect one LED driver to the LED engine. | map_sel 0; select LED0 as output |

| map_clr | x | Clear the LED driver mappings in an engine | map_clr |

| map_next | x | Select the next address in the LED mapping table and set that address active. | map_next |

| map_prev | x | Select the previous address in the LED mapping table and set that address active. | map_prev |

| load_next | Move the mapping-table pointer to the next address. | load_next | |

| load_prev | Move the mapping-table pointer to the previous address. | load_prev | |

| load_addr | Set the mapping-table pointer to the assigned address. | load_addr 02h; set pointer to 02h | |

| map_addr | x | Set the mapping-table pointer to the assigned address and set that address active. | map_addr 02h; set mapping to 02h |

Table 6. Branch Instructions

| INSTRUCTION | USAGE | COMPILER EXAMPLE |

| rst | Reset program counter to zero. | Reset |

| branch(1) | Branch to address. The number of loops can be set to a value or do an infinite loop. | branch 20, loop1; do 20 loops to loop1 label |

| branch(2) | Branch to address. The loop count can be one of four variables A, B, C, or D. | ld ra, 20 branch ra, loop1; do 20 loops to loop1 label |

| int | Send an interrupt to the host system by pulling the GPIO/TRIG/INT pin low. | int |

| end | End program execution and reset the program counter to zero. Can also the set GPIO/TRIG/INT pin high and/or reset mapped LED PWM and engine LED mapping. | end; end and reset LEDs. |

| trigger | Wait or send trigger. The trigger can be sent or received from an external pin or another engine. | trigger w{e}; wait for external trigger |

| trig_clear(3) | Clear pending triggers. | trig_clear |

| jne | Jump if not equal. A != B | Jump to loop1 if A != B: jne ra, rb, loop1 |

| jl | Jump if less. A < B | Jump to loop1 if A < B : jl ra, rb, loop1 |

| jge | Jump if greater or equal. A ≥ B | Jump to loop1 if A >= B: jge ra, rb, loop1 |

| je | Jump if equal. A = B | Jump to loop1 if A = B: je ra, rb, loop1 |

Table 7. Data Transfer and Arithmetic

| INSTRUCTION | USAGE | COMPILER EXAMPLE |

| ld(1) | Assign a value to a variable. | ld ra, 33; load value 33h to local variable A |

| add(1) | Add the 8-bit value to the variable value. | add ra, 11; add value 11h to local variable A |

| add(2) | Add the value of variable 3 (global variable D) to the value of variable 2 (global variable C) and store the result in variable 1 (local variable A). | add ra, rc, rd; add the value in rd to rc and store in ra |

| sub(1) | Subtract the 8-bit value from the variable value. | sub ra, 11; subtract value 11h from local variable A |

| sub(2) | Subtract the value of variable 3 (global variable D) from the value of variable 2 (global variable C) and store the result in variable 1 (local variable A). | sub ra, rc, rd; subtract the value in rd from rc and store in ra |

8.5.2.4 LED Driver Instructions

Table 8. LP5569 LED Driver Instructions

| INST. | Bit [15] | Bit [14] | Bit [13] | Bit [12] | Bit [11] | Bit [10] | Bit [9] | Bit [8] | Bit [7] | Bit [6] | Bit [5] | Bit [4] | Bit [3] | Bit [2] | Bit [1] | Bit [0] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ramp(1) | 0 | pre- scale | step time | sign | no. of increments | |||||||||||

| ramp(2) | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | pre- scale | sign | step time | no. of increments | ||

| set_pwm(1) | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | PWM value | |||||||

| set_pwm(2) | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | PWM value | |

| wait | 0 | pre- scale | time | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||||

8.5.2.4.1 Ramp

This is the instruction useful for smoothly changing from one PWM value into another PWM value on the LED0 to LED8 outputs —in other words, generating ramps with a negative or positive slope. The LP5569 device allows the programming of very fast and very slow ramps using only a single instruction. Full ramp 0 to 255 ramp time ranges from 124 ms to 4 s.

The ramp instruction generates a PWM ramp, using the effective PWM value as a starting value. At each ramp step the output is incremented or decremented by 1, unless the number of increments is 0. The time span for one ramp step is defined with the prescale bit [14] and step-time bits [13:9]. The ramp instruction controls the eight most-significant bits (MSB) of the PWM values and the remaining bits are interpolated as ramp mid-values internally for smoother transition.

Prescale = 0 sets a 0.49-ms cycle time and prescale = 1 sets a 15.6-ms cycle time; so the minimum time span for one step is 0.49 ms (prescale × step time span = 0.49 ms × 1) and the maximum time span is 15.6 ms × 31 = 484 ms/step. If all the step-time bits [13:9] are set to zero, the output value is incremented or decremented during one prescale on the whole time cycle.

The number-of-increments value defines how many steps are taken during one ramp instruction: the increment maximum value is 255, which corresponds to an increment from zero value to the maximum value. If PWM reaches the minimum or maximum value (0 or 255) during the ramp instruction, the ramp instruction is executed to the end regardless of saturation. This enables ramp instruction to be used as a combined ramp-and-wait instruction. Note: the ramp instruction is a wait instruction when the increment bits [7:0] are set to zero.

Programming ramps with variables is very similar to programming ramps with numerical operands. The only difference is that step time and number of increments are captured from variable registers when the instruction execution is started. If the variables are updated after starting the instruction execution, it has no effect on instruction execution. Again, at each ramp step the output is incremented or decremented by 1 unless the step time is 0 or the number of increments is 0. The time span for one step is defined with the prescale and step-time bits. The step time is defined with variable A, B, C, or D. Variable A is set by an I2C write to the engine 1, 2, or 3 variable A register or the ld instruction, variables B and C are set with the ld instruction, and variable D is set by an I2C write to the variable D register.

Setting the EXP_EN bit of registers 07h–0Fh high or low sets the exponential (1) or linear ramp (0). By using the exponential ramp setting, the visual effect appears like a linear ramp to the human eye.

Table 9. Ramp Instructions

| INST. | Bit [15] | Bit [14] | Bit [13] | Bit [12] | Bit [11] | Bit [10] | Bit [9] | Bit [8] | Bit [7] | Bit [6] | Bit [5] | Bit [4] | Bit [3] | Bit [2] | Bit [1] | Bit [0] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ramp(1) | 0 | pre- scale | step time | sign | no. of increments | |||||||||||

| ramp(1) | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | pre- scale | sign | step-time variable | no.-of-increments variable | ||

| PARAMETER NAME | NUMERIC OR VARIABLE | VALUE (d) | DESCRIPTION |

|---|---|---|---|

| prescale | Numeric | 0 | 32.7 kHz / 16 ≥ 0.488 ms cycle time |

| 1 | 32.7 kHz / 512 ≥ 15.625 ms cycle time | ||

| sign | Numeric | 0 | Increase PWM output |

| 1 | Decrease PWM output | ||

| step time | Numeric | 1–31 | One ramp increment done is in step time × prescale. Value in the variable A, B, C, or D must be from 1 to 31 for correct operation. |

| Variable | 0–3 | ||

| no. of increments | Numeric | 0–255 | The number of ramp cycles. Variables A to D as input. |

| Variable | 0–3 |

8.5.2.4.2 Ramp Instruction Application Example

An example of generating a 1.5-s ramp from PWM value 140 (approximately 55%) to 148 (approximately 58%). The ramp instruction uses relative values, so in this example we must ramp 8 steps up, as shown in Figure 25. The parameters for the RAMP instruction are:

- Positive ramp → sign = 0 (increase by 1)

- Step from 140 to 148 → no. of increments = 8

- Ramp time 1.5 s → 1.5 s / 8 steps = 187.5 ms/step

- Prescale = 1 → 15.625 ms cycle time

- 187.5 ms / 15.625 ms = 12 → step time = 12

Figure 25. Example of Ramp Instruction

Figure 25. Example of Ramp Instruction

8.5.2.4.3 Set_PWM

This instruction is used for setting the PWM value on outputs LED0 to LED8 without any ramps. Set the PWM output value from 0 to 255 with PWM value bits [7:0]. Instruction execution takes 16 32-kHz clock cycles

(= 488 µs).

8.5.2.4.4 Wait

When a wait instruction is executed, the engine is set in wait status, and the PWM values on the outputs are frozen. Note: A wait instruction with prescale and time = 0 is invalid and is executed as rst.

| NAME | VALUE (d) | DESCRIPTION |

|---|---|---|

| prescale | 0 | Divide master clock (32.7 kHz) by 16 which means 0.488 ms cycle time. |

| 1 | Divide master clock (32.7 kHz) by 512 which means 15.625 ms cycle time. | |

| time | 1–31 | Total wait time is = (time) × (prescale). Maximum 484 ms, minimum 0.488 ms. |

8.5.2.5 LED Mapping Instructions

These instructions define the engine-to-LED mapping. The mapping information is stored in a table, which is stored in the lower half of SRAM (program memory of the LP5569 device). The LP5569 device has three program execution engines which can be mapped to nine LED drivers. One engine can control one or multiple LED drivers. Execution engine 1 has priority over execution engines 2 and 3, with execution engine 2 having priority over execution engine 3. If an LED is mapped to more than one execution engine, the higher-priority engine controls the LED.

LED mapping instructions can be divided to two groups:

- Instructions that activate LED mapping to a certain row of the table (map_ instructions).

- Instructions that DO NOT activate the actual LED mapping but just shift the mapping-table pointer (load_ instructions).

When an engine is actively mapped to the LEDs, the engine takes over the LED PWM control, and PWM control registers have no effect. Register control is returned when the engine is mapped to another LED. See Figure 26 for a simplified diagram of LED-engine data flow. The engine does not push a new PWM value to the LED driver output before the set_pwm or ramp instruction is executed. If the mapping has been released from an LED, the value in the PWM register still controls the LED brightness, and the PWM register value remains in the last engine state.

Actual PWM control resolution of the LED engines is 12 bits, but only the 8 highest bits are visible in the I2C registers. Also, engine commands use the 8 high bits for control, and the 4 low bits are used for smoother ramps.

Figure 26. LED Data Flow

Figure 26. LED Data Flow

All LED mapping instructions use the SRAM bit to LEDx pin mapping as shown in Table 10.

Table 10. LED Mapping Bits in SRAM

| Bit [15] | Bit [14] | Bit [13] | Bit [12] | Bit [11] | Bit [10] | Bit [9] | Bit [8] | Bit[7] | Bit[6] | Bit[5] | Bit[4] | Bit[3] | Bit[2] | Bit[1] | Bit 0 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LED mapping table in SRAM | — | — | — | — | — | — | 0 | LED8 | LED7 | LED6 | LED5 | LED4 | LED3 | LED2 | LED1 | LED0 |

Bit[9] is to enable master fader control by the engine. If this bit is set to 1 in engine 1, then master fader 1 is enabled.

Table 11. LP5569 LED Mapping Instructions

| INST. (1) | Bit [15] | Bit [14] | Bit [13] | Bit [12] | Bit [11] | Bit [10] | Bit [9] | Bit [8] | Bit [7] | Bit [6] | Bit [5] | Bit [4] | Bit [3] | Bit [2] | Bit [1] | Bit [0] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| load_start | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | SRAM addresses 0–127(2) | ||||||

| map_start | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | SRAM addresses 0–127(2) | ||||||

| load_end | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 0 | 1 | SRAM addresses 0–127(2) | ||||||

| map_sel | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | LED select(3) | ||||||

| map_clr | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| map_next | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| map_prev | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| load_next | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| load_prev | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 |

| load_addr | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | SRAM addresses 0–127(2) | ||||||

| map_addr | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | SRAM addresses 0–127(2) | ||||||

8.5.2.5.1 LOAD_START and LOAD_END

The load_start and load_end instructions define the mapping table locations in SRAM.

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| SRAM address | 0–127 | Mapping table start or end address restricted to lower half of memory. | |

8.5.2.5.2 MAP_START

The map_start instruction defines the mapping table start address in the memory, and the first row of the table is activated (mapped) at the same time.

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| SRAM address | 0–127 | Mapping table start address restricted to lower half of memory. | |

8.5.2.5.3 MAP_SEL

With the map_sel instruction one, and only one, LED driver can be connected to a program execution engine. Connecting multiple LEDs to one engine is done with the mapping table. After the mapping has been released from an LED, the PWM register value still controls the LED brightness.

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| LED select | 0–127 | 0 = no drivers selected | |

| 1 = LED1 selected | |||

| 2 = LED1 selected | |||

| ... | |||

| 9 = LED9 selected | |||

| 10–127 = no drivers selected | |||

8.5.2.5.4 MAP_CLR

The map_clr instruction clears engine-to-driver mapping. After the mapping has been released from an LED, the PWM register value still controls the LED brightness.

8.5.2.5.5 MAP_NEXT

This instruction sets the next row active in the mapping table each time it is called. For example, if the second row is active at this moment, after the map_next instruction call the third row is active. If the mapping table end address is reached, activation rolls to the mapping-table start address the next time when the map_next instruction is called. The engine does not push a new PWM value to the LED driver output before the set_pwm or ramp instruction is executed. If the mapping has been released from an LED, the value in the PWM register still controls the LED brightness.

8.5.2.5.6 LOAD_NEXT

Similar to the map_next instruction with the exception that no mapping is set. The index pointer is set to point to the next row and the engine-to-LED-driver connection is not updated.

8.5.2.5.7 MAP_PREV

This instruction sets the previous row active in the mapping table each time it is called. For example, if the third row is active at this moment, after the map_prev instruction call the second row is active. If the mapping table start address is reached, activation rolls to the mapping table end address next time the map_prev instruction is called. The engine does not push a new PWM value to the LED driver output before the set_pwm or ramp instruction is executed. If the mapping has been released from an LED, the value in the PWM register still controls the LED brightness.

8.5.2.5.8 LOAD_PREV

Similar to the map_prev instruction with the exception that no mapping is set. The index pointer is set to point to the previous row and the engine-to-LED-driver connection is not updated.

8.5.2.5.9 MAP_ADDR

The map_addr instruction sets the index pointer to point to the mapping table row defined by bits [6:0] and sets the row active. The engine does not push a new PWM value to the LED driver output before the set_pwm or ramp instruction is executed. If the mapping has been released from an LED, the value in the PWM register still controls the LED brightness.

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| SRAM address | 0–127 | SRAM address containing mapping data restricted to lower half of memory. | |

8.5.2.5.10 LOAD_ADDR

The load_addr instruction sets the index pointer to point to the mapping table row defined by bits [6:0], but the row is not set active.

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| SRAM address | 0–127 | SRAM address containing mapping data restricted to lower half of memory. | |

8.5.2.6 Branch Instructions

8.5.2.6.1 BRANCH

The branch instruction is provided for repeating a portion of the program code several times. The branch instruction loads a step number value to the program counter. A loop count parameter defines how many times the instructions inside the loop are repeated. The step number is loaded into the PC when the instruction is executed. The PC is relative to the ENGINEx_PROG_START register setting. The LP5569 device supports nested looping, that is, a loop inside a loop. The number of nested loops is not limited. The instruction takes 16 32-kHz clock cycles.

Table 12. LP5569 Branch Instructions

| INST. | Bit [15] | Bit [14] | Bit [13] | Bit [12] | Bit [11] | Bit [10] | Bit [9] | Bit [8] | Bit [7] | Bit [6] | Bit [5] | Bit [4] | Bit [3] | Bit [2] | Bit [1] | Bit [0] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| rst | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| branch(1) | 1 | 0 | 1 | loop count | step number | |||||||||||

| branch(2) | 1 | 0 | 0 | 0 | 0 | 1 | 1 | step number | loop count | |||||||

| int | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| end | 1 | 1 | 0 | int | reset | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| trigger | 1 | 1 | 1 | wait for trigger | send a trigger | 0 | ||||||||||

| ext trig | X(3) | X(3) | E3 | E2 | E1 | ext trig | X(3) | X(3) | E3 | E2 | E1 | |||||

| trig_clear (4) |

1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| jne | 1 | 0 | 0 | 0 | 1 | 0 | 0 | Number of instructions to be skipped if the operation returns true | variable 1 | variable 2 | ||||||

| jl | 1 | 0 | 0 | 0 | 1 | 0 | 1 | Number of instructions to be skipped if the operation returns true | variable 1 | variable 2 | ||||||

| jge | 1 | 0 | 0 | 0 | 1 | 1 | 0 | Number of instructions to be skipped if the operation returns true | variable 1 | variable 2 | ||||||

| je | 1 | 0 | 0 | 0 | 1 | 1 | 1 | Number of instructions to be skipped if the operation returns true | variable 1 | variable 2 | ||||||

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| loop count(1) | 0–63 | The number of loops to be done. 0 means an infinite loop. | |

| step number | 0–127 | The step number to be loaded to program counter. | |

| loop count(2) | 0–3 | Selects the variable for loop count value. Loop count is loaded with the value of the variable defined below. | |

| 0 = Local variable A | |||

| 1 = Local variable B | |||

| 2 = Global variable C | |||

| 3 = Global variable D | |||

8.5.2.6.2 INT

Send an interrupt to the processor by pulling the INT pin down and setting the corresponding status bit high. Interrupts can be cleared by reading the interrupt bits in the ENGINE_STATUS register at address 3Ch.

8.5.2.6.3 RST

The rst instruction resets the program counter register (address 30h, 31h, or 32h) and continues executing the program from the program the start address defined in register addresses 4Bh–4Dh. The instruction takes 16 32‑kHz clock cycles. Note that default value for all program memory registers is 0000h, which is the rst instruction.

8.5.2.6.4 END

End program execution. The instruction takes 16 32-kHz clock cycles.

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| int | 0 | No interrupt is sent. PWM register values remain intact. | |

| 1 | Reset program counter value to 0 and send interrupt to processor by pulling the INT pin down and setting the corresponding status bit high to notify that the program has ended. PWM register values remain intact. Interrupts can be cleared by reading the interrupt bits in STATUS/INTERRUPT register at address 3Ch. | ||

| reset | 0 | Reset program counter value to 0 and hold. PWM register values remain intact. | |

| 1 | Reset program counter value to 0 and hold. PWM register values of the non-mapped drivers remain. PWM register values of the mapped drivers are set to 0000 0000b. | ||

8.5.2.6.5 TRIGGER and TRIG_CLEAR

The wait-for-trigger or send-a-trigger instruction can be used to synchronize operation between the program execution engines. Sending a trigger instruction takes 16 32-kHz clock cycles and waiting for a trigger takes at least 16 32-kHz clock cycles. The receiving engine stores the triggers that have been sent. Received triggers are cleared by the wait-for-trigger instruction or trig_clear instruction. The wait-for-trigger instruction is executed until all the defined triggers have been received. (Note: several triggers can be defined in the same instruction.) The external-trigger input signal must stay low for at least two 32-kHz clock cycles to be executed. The trigger output signal is three 32-kHz clock cycles long. The external trigger signal is active-low; for example, when a trigger is sent or received, the pin is pulled to GND. Sending an external trigger is masked; that is, the device which has sent the trigger does not recognize the trigger it sent. If send and wait external triggers are used on the same instruction, the send external trigger is executed first, followed by the wait external trigger.

The trig_clear instruction clears pending triggers for a single execution engine. Use this instruction in each execution engine at the beginning of program execution to clear any pending triggers. Pending triggers are always cleared whenever the engine mode is in the disabled state or load program to SRAM (see SRAM Memory).

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| wait for trigger | 0–31 | Wait for trigger from the engine(s). Several triggers can be defined in the same instruction. Bit [7]: Wait for trigger from engine 1. Bit [8]: Wait for trigger from engine 2. Bit [9]: Wait for trigger from engine 3. Bit [12]: Wait for trigger from GPIO/TRIG/INT pin. Bits [10] and [11] are not used. |

|

| send a trigger | 0–31 | Send a trigger to the engine(s). Several triggers can be defined in the same instruction. Bit [1]: Send trigger to engine 1. Bit [2]: Send trigger to engine 2. Bit [3]: Send trigger to engine 3. Bit [6]: Send trigger to GPIO/TRIG/INT pin. Bits [4] and [5]: are not used. |

|

8.5.2.6.6 JNE, JGE, JL, and JE

The LP5569 instruction set includes the following conditional jump instructions: jne (jump if not equal); jge (jump if greater or equal); jl (jump if less); je (jump if equal). If the condition is true, a certain number of instructions are skipped (that is, the program jumps forward to a location relative to the present location). If the condition is false, the next instruction is executed.

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| Number of instructions to be skipped if the operation returns true. | 0–31 | The number of instructions to be skipped when the statement is true. Note: value 0 means redundant code. |

|

| variable 1 | 0–3 | Defines the variable to be used in the test: 0 = Local variable A 1 = Local variable B 2 = Global variable C 3 = Global variable D |

|

| variable 2 | 0–3 | Defines the variable to be used in the test: 0 = Local variable A 1 = Local variable B 2 = Global variable C 3 = Global variable D |

|

8.5.2.7 Data Transfer and Arithmetic Instructions

Table 13. LP5569 Data Transfer and Arithmetic Instructions

| INST. | Bit [15] | Bit [14] | Bit [13] | Bit [12] | Bit [11] | Bit [10] | Bit [9] | Bit [8] | Bit [7] | Bit [6] | Bit [5] | Bit [4] | Bit [3] | Bit [2] | Bit [1] | Bit [0] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ld | 1 | 0 | 0 | 1 | target variable | 0 | 0 | 8-bit value 0 | ||||||||

| add(1) | 1 | 0 | 0 | 1 | target variable | 0 | 1 | 8-bit value 0 | ||||||||

| add(2) | 1 | 0 | 0 | 1 | target variable | 1 | 1 | 0 | 0 | 0 | 0 | var 1 | var 2 | |||

| sub(1) | 1 | 0 | 0 | 1 | target variable | 1 | 0 | |||||||||

| sub(2) | 1 | 0 | 0 | 1 | target variable | 1 | 1 | 0 | 0 | 0 | 1 | var 1 | var 2 | |||

8.5.2.7.1 LD

This instruction is used to assign a value into a variable; the previous value in that variable is overwritten. Each of the engines has two local variables, called A and B. The variable C is a global variable.

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| target variable | 0–2 | 0 = Variable A 1 = Variable B 2 = Variable C |

|

| 8-bit value | 0–255 | Variable value | |

8.5.2.7.2 ADD

This operator either adds an 8-bit value to the current value of the target variable, or adds the value of variable 1 (A, B, C, or D) to the value of variable 2 (A, B, C, or D) and stores the result in the register of variable A, B, or C. Variables overflow from 255 to 0.

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| 8-bit value(1) | 0–255 | The value to be added. | |

| target variable | 0–2 | 0 = Variable A 1 = Variable B 2 = Variable C |

|

| variable 1(2) | 0–3 | 0 = Local variable A 1 = Local variable B 2 = Global variable C 3 = Global variable D |

|

| variable 2(2) | 0–3 | 0 = Local variable A 1 = Local variable B 2 = Global variable C 3 = Global variable D |

|

8.5.2.7.3 SUB

The SUB operator either subtracts an 8-bit value from the current value of the target variable, or subtracts the value of variable 2 (A, B, C, or D) from the value of variable 1 (A, B, C, or D) and stores the result in the register of the target variable (A, B, or C). Variables overflow from 0 to 255.

| NAME | VALUE (d) | DESCRIPTION | |

|---|---|---|---|

| 8-bit value(1) | 0–255 | The value to be subtracted. | |

| target variable | 0–2 | 0 = Variable A 1 = Variable B 2 = Variable C |

|

| variable 1(2) | 0–3 | 0 = Local variable A 1 = Local variable B 2 = Global variable C 3 = Global variable D |

|

| variable 2(2) | 0–3 | 0 = Local variable A 1 = Local variable B 2 = Global variable C 3 = Global variable D |

|

8.6 Register Maps

8.6.1 LP5569_MAP Registers

Table 14 lists the memory-mapped registers for the LP5569_MAP. All register offset addresses not listed in Table 14 should be considered as reserved locations and the register contents should not be modified.

Table 14. LP5569_MAP Registers

| ADDRESS | ACRONYM | REGISTER NAME | SECTION |

|---|---|---|---|

| 0h | CONFIG | Configuration Register | Go |

| 1h | LED_ENGINE_CONTROL1 | Engine Execution Control Register | Go |

| 2h | LED_ENGINE_CONTROL2 | Engine Operation Mode Register | Go |

| 7h | LED0_CONTROL | LED0 Control Register | Go |

| 8h | LED1_CONTROL | LED1 Control Register | Go |

| 9h | LED2_CONTROL | LED2 Control Register | Go |

| Ah | LED3_CONTROL | LED3 Control Register | Go |

| Bh | LED4_CONTROL | LED4 Control Register | Go |

| Ch | LED5_CONTROL | LED5 Control Register | Go |

| Dh | LED6_CONTROL | LED6 Control Register | Go |

| Eh | LED7_CONTROL | LED7 Control Register | Go |

| Fh | LED8_CONTROL | LED8 Control Register | Go |

| 16h | LED0_PWM | LED0 PWM Duty Cycle | Go |

| 17h | LED1_PWM | LED1 PWM Duty Cycle | Go |

| 18h | LED2_PWM | LED2 PWM Duty Cycle | Go |

| 19h | LED3_PWM | LED3 PWM Duty Cycle | Go |

| 1Ah | LED4_PWM | LED4 PWM Duty Cycle | Go |

| 1Bh | LED5_PWM | LED5 PWM Duty Cycle | Go |

| 1Ch | LED6_PWM | LED6 PWM Duty Cycle | Go |

| 1Dh | LED7_PWM | LED7 PWM Duty Cycle | Go |

| 1Eh | LED8_PWM | LED8 PWM Duty Cycle | Go |

| 22h | LED0_CURRENT | LED0 Current Control | Go |

| 23h | LED1_CURRENT | LED1 Current Control | Go |

| 24h | LED2_CURRENT | LED2 Current Control | Go |

| 25h | LED3_CURRENT | LED3 Current Control | Go |

| 26h | LED4_CURRENT | LED4 Current Control | Go |

| 27h | LED5_CURRENT | LED5 Current Control | Go |

| 28h | LED6_CURRENT | LED6 Current Control | Go |

| 29h | LED7_CURRENT | LED7 Current Control | Go |

| 2Ah | LED8_CURRENT | LED8 Current Control | Go |

| 2Fh | MISC | I2C, Charge Pump and Clock Configuration | Go |

| 30h | ENGINE1_PC | Engine1 Program Counter | Go |

| 31h | ENGINE2_PC | Engine2 Program Counter | Go |

| 32h | ENGINE3_PC | Engine3 Program Counter | Go |

| 33h | MISC2 | Charge Pump and LED Configuration | Go |

| 3Ch | ENGINE_STATUS | Engine 1, 2 & 3 Status | Go |

| 3Dh | IO_CONTROL | TRIG, INT and CLK Configuration | Go |

| 3Eh | VARIABLE_D | Global Variable D | Go |

| 3Fh | RESET | Software Reset | Go |

| 42h | ENGINE1_VARIABLE_A | Engine 1 Local Variable A | Go |

| 43h | ENGINE2_VARIABLE_A | Engine 2 Local Variable A | Go |

| 44h | ENGINE3_VARIABLE_A | Engine 3 Local Variable A | Go |

| 46h | MASTER_FADER1 | Engine 1 Master Fader | Go |

| 47h | MASTER_FADER2 | Engine 2 Master Fader | Go |

| 48h | MASTER_FADER3 | Engine 3 Master Fader | Go |

| 4Ah | MASTER_FADER_PWM | PWM Input Duty Cycle | Go |

| 4Bh | ENGINE1_PROG_START | Engine 1 Program Starting Address | Go |

| 4Ch | ENGINE2_PROG_START | Engine 2 Program Starting Address | Go |

| 4Dh | ENGINE3_PROG_START | Engine 2 Program Starting Address | Go |

| 4Fh | PROG_MEM_PAGE_SELECT | Program Memory Page Select | Go |

| 50h | PROGRAM_MEM_00 | MSB 0 | Go |

| 51h | PROGRAM_MEM_01 | LSB 0 | Go |

| 52h | PROGRAM_MEM_02 | MSB 1 | Go |

| 53h | PROGRAM_MEM_03 | LSB 1 | Go |

| 54h | PROGRAM_MEM_04 | MSB 2 | Go |

| 55h | PROGRAM_MEM_05 | LSB 2 | Go |

| 56h | PROGRAM_MEM_06 | MSB 3 | Go |

| 57h | PROGRAM_MEM_07 | LSB 3 | Go |

| 58h | PROGRAM_MEM_08 | MSB 4 | Go |

| 59h | PROGRAM_MEM_09 | LSB 4 | Go |

| 5Ah | PROGRAM_MEM_10 | MSB 5 | Go |

| 5Bh | PROGRAM_MEM_11 | LSB 5 | Go |

| 5Ch | PROGRAM_MEM_12 | MSB 6 | Go |

| 5Dh | PROGRAM_MEM_13 | LSB 6 | Go |

| 5Eh | PROGRAM_MEM_14 | MSB 7 | Go |

| 5Fh | PROGRAM_MEM_15 | LSB 7 | Go |

| 60h | PROGRAM_MEM_16 | MSB 8 | Go |

| 61h | PROGRAM_MEM_17 | LSB 8 | Go |

| 62h | PROGRAM_MEM_18 | MSB 9 | Go |

| 63h | PROGRAM_MEM_19 | LSB 9 | Go |

| 64h | PROGRAM_MEM_20 | MSB 10 | Go |

| 65h | PROGRAM_MEM_21 | LSB 10 | Go |

| 66h | PROGRAM_MEM_22 | MSB 11 | Go |

| 67h | PROGRAM_MEM_23 | LSB 11 | Go |

| 68h | PROGRAM_MEM_24 | MSB 12 | Go |

| 69h | PROGRAM_MEM_25 | LSB 12 | Go |

| 6Ah | PROGRAM_MEM_26 | MSB 13 | Go |

| 6Bh | PROGRAM_MEM_27 | LSB 13 | Go |

| 6Ch | PROGRAM_MEM_28 | MSB 14 | Go |

| 6Dh | PROGRAM_MEM_29 | LSB 14 | Go |

| 6Eh | PROGRAM_MEM_30 | MSB 15 | Go |

| 6Fh | PROGRAM_MEM_31 | LSB 15 | Go |

| 70h | ENGINE1_MAPPING1 | Engine 1 LED [8] and Master Fader Mapping | Go |

| 71h | ENGINE1_MAPPING2 | Engine 1 LED [7:0] Mapping | Go |

| 72h | ENGINE2_MAPPING1 | Engine 2 LED [8] and Master Fader Mapping | Go |

| 73h | ENGINE2_MAPPING2 | Engine 2 LED [7:0] Mapping | Go |

| 74h | ENGINE3_MAPPING1 | Engine 3 LED [8] and Master Fader Mapping | Go |

| 75h | ENGINE3_MAPPING2 | Engine 3 LED [7:0] Mapping | Go |

| 80h | PWM_CONFIG | PWM Input Configuration | Go |

| 81h | LED_FAULT1 | LED [8] Fault Status | Go |

| 82h | LED_FAULT2 | LED [7:0] Fault Status | Go |

| 83h | GENERAL_FAULT | CP Cap, UVLO and TSD Fault Status | Go |

Table 15. Register Access-Type Codes

| Access Type | Code | Description |

|---|---|---|

| Read Type | ||

| R | R | Read |

| Write Type | ||

| W | W | Write |

| Reset or Default Value | ||

| -n | Value after reset or the default value | |

8.6.1.1 CONFIG Register (Address = 0h) [reset = 0h]

CONFIG is shown in Figure 27 and described in Table 16.

Return to Summary Table.

Configuration Register

| 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 |

| RESERVED | chip_en | RESERVED | |||||

| R/W-0h | R/W-0h | R/W-0h | |||||

8.6.1.2 LED_ENGINE_CONTROL1 Register (Address = 1h) [reset = 0h]

LED_ENGINE_CONTROL1 is shown in Figure 28 and described in Table 17.

Return to Summary Table.

LED Engine Control Register 1

Execution states are defined in this register, and they are only applicable when the corresponding mode register in LED_ENGINE_CONTROL2 is set to the run mode. Execution-state values may be written by the host in other modes, but the engine disregards the write until the mode changes to run mode. The fields in this register define how the program is executed out of SRAM:

HOLD: The engine does not execute any instructions, but the program counter holds its current value unless overwritten by the host. This is the only state in which the PC can be written.

STEP: Executes a single instruction, increments the PC, and then changes to the hold state. If the instruction is a ramp or wait, the engine waits for this instruction to complete before changing to the hold state.

FREE RUN: The engine begins instruction execution from the current value of the PC. The program counter is reset to zero when its upper-limit value is reached at the top of SRAM memory.

EXECUTE ONCE: Executes a single instruction and then changes to the hold state. The PC remains unaffected unless the instruction is a branch command, in which case it changes if the branch is taken. If the instruction is a ramp or wait, it waits for this instruction to complete before changing to hold state.

| 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 |

| ch1_exec | ch2_exec | ch3_exec | RESERVED | ||||

| R/W-0h | R/W-0h | R/W-0h | R/W-0h | ||||

Table 17. LED_ENGINE_CONTROL1 Register Field Descriptions

8.6.1.3 LED_ENGINE_CONTROL2 Register (Address = 2h) [reset = 0h]

LED_ENGINE_CONTROL2 is shown in Figure 29 and described in Table 18.

Return to Summary Table.

LED Engine Control Register 2

Operation modes are defined in this register.

DISABLED: Engines each can be configured to be disabled independently. When disabled, the program counter per ENGINEx_PC is set to 0 and the engine does not execute instructions.

LOAD PROGRAM: Writing to program memory is allowed only when the engine is in the load-program operation mode and the engine-busy bit (register 3C) is not set. The host should check the engine-busy bit before writing to program memory or allow at a least 1-ms delay after entering the load mode before memory write, to ensure initialization. If any engine is set to the load-program mode, then the other engines should be set either to the disabled or load-program mode, because they are inhibited from executing instructions while loading the SRAM. The load-program mode also resets the program counter of the respective engine. The load-program mode can only be entered from the disabled mode.

RUN PROGRAM: The run-program mode executes the instructions stored in the program memory. Execution register (LED_ENGINE_CONTROL1) bits define how the program is executed (hold, step, free-run or execute once).

HALT: Instruction execution aborts immediately and engine operation halts.

| 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 |

| ch1_mode | ch2_mode | ch3_mode | RESERVED | ||||

| R/W-0h | R/W-0h | R/W-0h | R/W-0h | ||||

Table 18. LED_ENGINE_CONTROL2 Register Field Descriptions