-

Pre-Regulated Isolated Driver Bias Supply Reference Design for Traction-Inverter Applications

Pre-Regulated Isolated Driver Bias Supply Reference Design for Traction-Inverter Applications

1 Description

This pre-regulated isolated open-loop LLC transformer driver converter provides four 18-V outputs up to a total of 6 W for traction-inverter applications. The LLC topology allows the transformer to have significant leakage inductance, but a much smaller primary-secondary capacitance, which significantly reduces common-mode current injection through the bias transformer. The boost pre-regulator is designed to provide 7.5 W to the LLC converter, which can support a maximum of 6-W output.

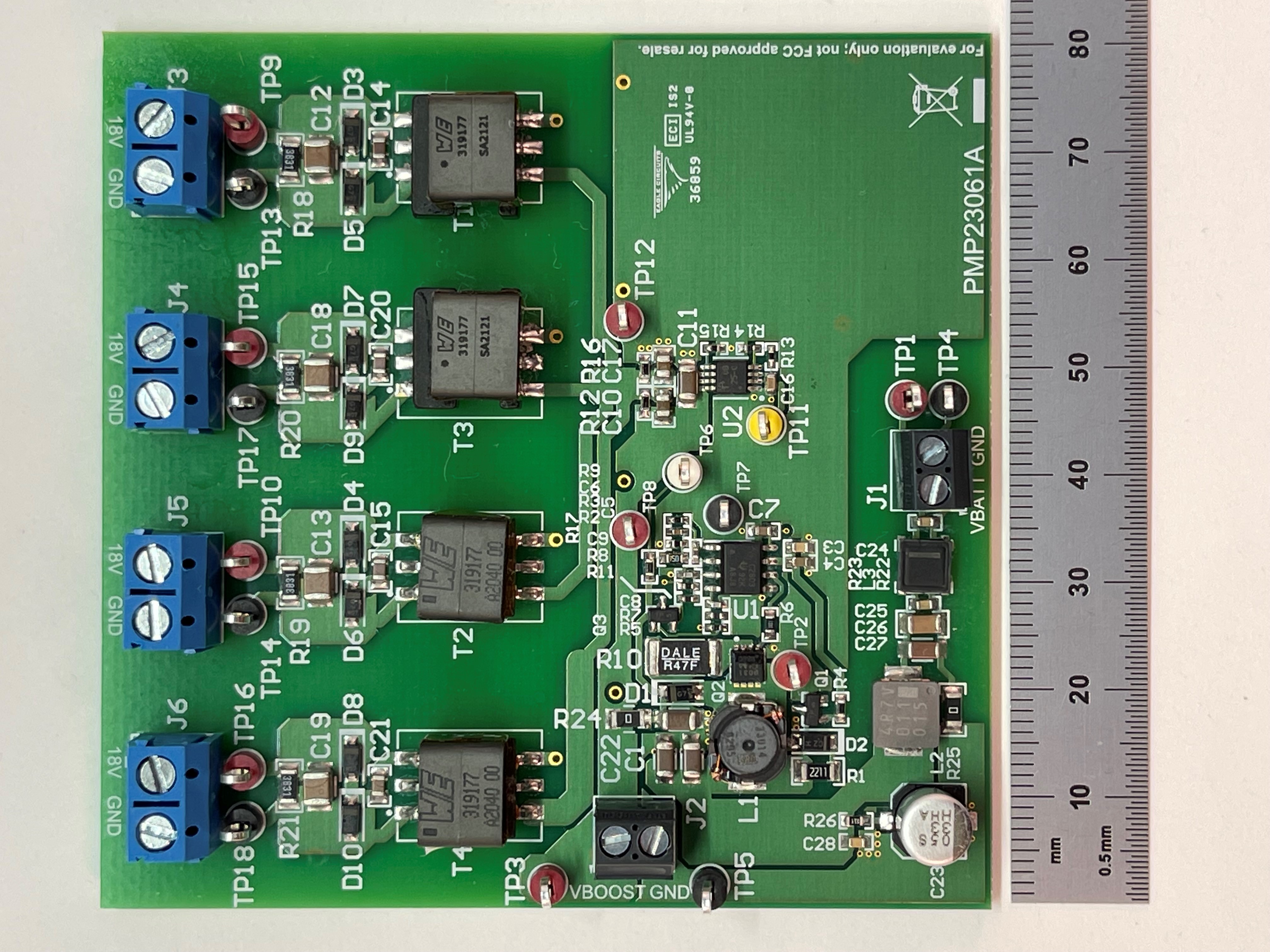

Figure 1-1 Top Photo

Figure 1-1 Top Photo2 Test Prerequisites

2.1 Voltage and Current Requirements

| Parameter | Specifications |

|---|---|

| Input voltage range | 6 V–28 V |

| Output voltage and current | 4 × 18-V rails, 1 × 167 mA, 3 × 56 mA, 6 W maximum |

| Switching frequency | Boost: 300 kHz, LLC: 1 MHz |

| Isolation | Yes |

| Topology | Open-loop LLC transformer driver with boost pre-regulator |

2.2 Required Equipment

- Resistive loads

- Power supply capable of 30 V, 10 W minimum

- Oscilloscope and probes

- Digital multimeters

3 Testing and Results

3.1 Efficiency and Power Dissipation Graphs

The efficiency of the boost converter and the open-loop LLC were measured separately. For the boost measurements the LLC was disabled by shorting the DIS/FLT pin of the UCC25800-Q1 (TP11) to GND and a resistive load was applied across the connector labeled VBOOST (J2). Efficiency curves were measured for inputs of 6 V, 12 V, 24 V, and 28 V.

Figure 3-1 Boost Efficiency and Power Dissipation

Figure 3-1 Boost Efficiency and Power DissipationThe LLC measurements were taken with a regulated 30 V applied at the connector labeled VBOOST (J2) and with the boost input (J1) disconnected.

Figure 3-2 LLC Efficiency and Power Dissipation

Figure 3-2 LLC Efficiency and Power Dissipation3.2 Efficiency and Power Dissipation Data

The efficiency and power dissipation data for the boost and LLC stages is shown in the following tables.

Figure 3-3 Boost Converter Efficiency, 6

VIN

Figure 3-3 Boost Converter Efficiency, 6

VIN Figure 3-4 Boost Converter Efficiency, 12

VIN

Figure 3-4 Boost Converter Efficiency, 12

VIN Figure 3-5 Boost Converter Efficiency,

24VIN

Figure 3-5 Boost Converter Efficiency,

24VIN Figure 3-6 Boost Converter Efficiency, 28

VIN

Figure 3-6 Boost Converter Efficiency, 28

VIN Figure 3-7 LLC Converter Efficiency, 30

VIN

Figure 3-7 LLC Converter Efficiency, 30

VIN3.3 Thermal Performance

The following thermal image shows the board running with 6 VIN and 6 W being drawn from the 18-V LLC outputs (3 × 1 W and 1 × 3 W).

Figure 3-8 Top Thermal Image

Figure 3-8 Top Thermal Image3.4 Bode Plot

The loop stability of the boost converter is shown in the following plot. The plot was obtained with the LLC converter disabled and a resistive load applied across J2.

Figure 3-9 Loop Stability, 12 VIN, 250-mA

Load

Figure 3-9 Loop Stability, 12 VIN, 250-mA

Load