SSZTCY2 May 2023 UCC21710

There is an energy revolution happening across the world, where according to the International Energy Agency, renewable energy sources will account for almost 95% of the increase in global power capacity through 2026. Solar energy sources will make up more than half of that 95%.

Today, ambitious clean energy goals and government policies are accelerating the adoption of renewable energy in areas such as solar power, electric vehicle (EV) infrastructures and energy storage. Increased adoption introduces more opportunities for the deployment of power-conversion systems in industrial, commercial and residential applications. The adoption of wide band-gap devices such as silicon carbide (SiC) is helping designers achieve a balance between four performance indicators: efficiency, density, cost and reliability.

SiC’s advantages over traditional IGBT-based power applications in renewable energy

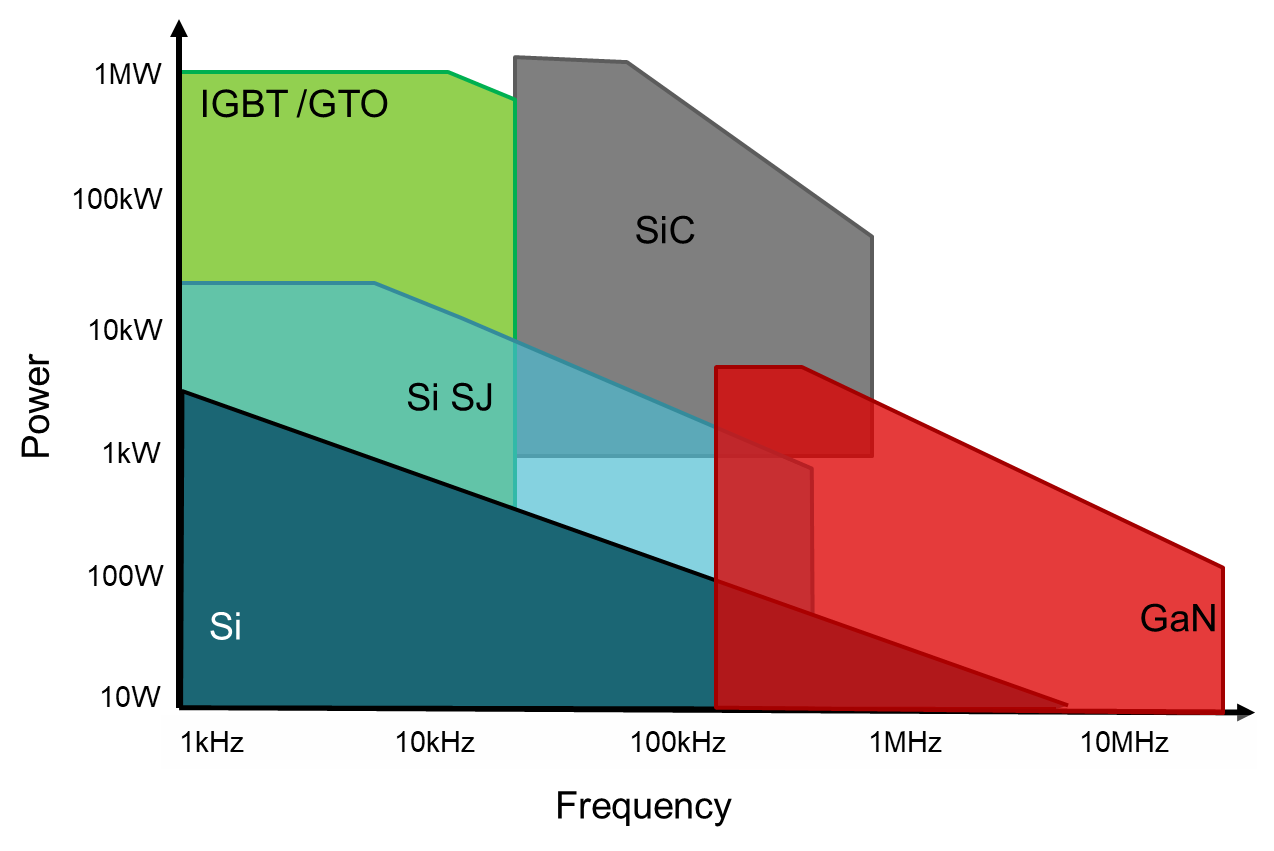

SiC power switches and insulated-gate bipolar transistors (IGBTs) are popular power switches in high-power applications such as renewable energy systems. Figure 1 shows the typical switching frequencies and power levels at which SiC power switches and IGBTs operate. Both have applicability at 1-kW power levels and higher.

Figure 1 Typical operating ranges for

power switches

Figure 1 Typical operating ranges for

power switchesSiC power switches have several performance advantages in high-power renewable energy when compared to traditional silicon power switches such as IGBTs.

The first performance advantage is a lower resistance and capacitance relative to IGBTs, which reduces power losses and helps improve efficiency. SiC power switches can support much higher switching speeds than IGBTs, which helps reduce switching losses and improves power-conversion efficiency. This translates to higher energy yields, which are imperative for maximizing the output of power converters in renewable systems such as solar inverters, energy storage systems or power modules in DC fast chargers.

Many renewable energy applications operate in small areas with high heat generation, leading designers to search for ways to shrink printed circuit board size and maximize heat dissipation. SiC can operate at higher temperatures than IGBTs, giving SiC power switches higher thermal and mechanical stability, which enables more compact designs for power electronics.

Driving SiC with a gate driver

Driving SiC power switches requires special considerations given their unique characteristics. Gate-driver selection can legitimately impact how SiC will perform in the application.

SiC power switches require gate drivers that can handle high voltage and current ratings. The gate driver must provide a sufficient gate charge to switch the SiC power switch and prevent voltage spikes.

Compared to IGBTs, SiC power switches are vulnerable to short circuits, which can significantly damage a power electronics system. Typically, IGBTs have a short-circuit withstand time of approximately 10 µs, whereas SiC’s short-circuit withstand time is approximately 2 µs. For this reason, it is important to consider adding elements of protection such as desaturation or overcurrent protection when designing with SiC power switches. Some gate drivers, such as the UCC21710 gate driver, have a built-in short-circuit protection feature to detect and respond to short-circuit events. To learn more about short-circuit protection for SiC FETs, see the application note, “Understanding the Short Circuit Protection for SiC MOSFETs.”

While SiC power switches can operate in higher-temperature environments, it is still important to monitor the thermal performance of SiC power switches and prevent overheating. In addition to a built-in short-circuit feature, the UCC21710 has an integrated sensor for monitoring, eliminating the need to implement a discrete temperature sensor.

Conclusion

To take full advantage of the power output in renewable energy systems, it’s important to maximize efficiency while balancing cost, size and reliability. SiC power switches have several advantages in high-power applications that make them great candidates for solar and EV charging. To maximize the impact that SiC can bring to these applications, TI offers gate-driver products optimized for SiC power switches that can scale in power levels – as well as different levels of integrated protection – to help simplify the design of a SiC power stage.

Additional resources

- Check out our reference designs featuring isolated gate drivers:

- Learn more about the UCC21710 single-channel isolated gate driver.