SSZTC15 october 2015 TPS62085 , TPS82085 , TPS8268180

With improvements in semiconductor and packaging technology, power modules have become increasingly popular and more accessible. With higher levels of integration, power modules enable a simpler design for engineers and occupy a smaller printed circuit board (PCB) area. But is a power module always the best solution for every design?

A power module integrates any number of required passives and the integrated circuit (IC) into a single device. For example, the 3A TPS82085 power module integrates the IC with both of its power MOSFETs, gate drivers, control loop and compensation, soft start, and other functionality. The power inductor is included as well. Then, engineers only need to add the input and output capacitors, feedback resistors, and an optional power good resistor. The 3A TPS62085 ‘non-module’ or discrete IC version requires the same passives plus the power inductor. Compared to the TPS82085 module, the TPS62085 is almost as simple. Finally, the 1.6A TPS8268180 power module includes all of the required components for a true single-device solution with no additional effort. This is the simplest solution with the highest integration level.

Integration doesn’t come for free, however – there are always trade-offs. For example, since a power module integrates various discrete components, it must have some way to connect them together. In the TPS82xxx MicroSiP family and many other modules, a PCB makes this possible. The IC is embedded in the PCB and the inductor or other passives are stacked on top, as shown in Figure 1. Clearly, this increases the solution height compared to putting the same IC and passives side by side.

Figure 1 A View of the TPS8268180

MicroSiP™ Showing the Passives Stacked on Top of Its PCB

Figure 1 A View of the TPS8268180

MicroSiP™ Showing the Passives Stacked on Top of Its PCBEven with the PCB, the TPS8268180 MicroSiP™ still supports a maximum height of just 1mm. This is more than sufficient for the majority of applications. Yet such a small height leads to the second trade-off: efficiency. A lower overall height requires a lower-height inductor, which increases the direct current resistance (DCR). Compared to a discrete IC, a power module will have a higher DCR inductor, resulting in lower efficiency at heavy loads.

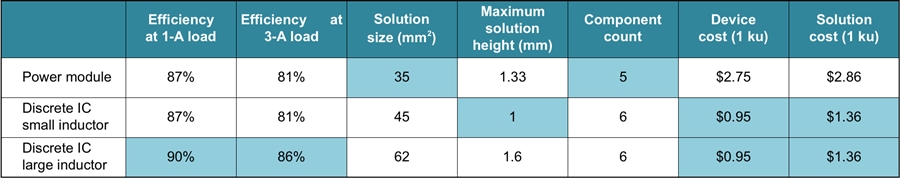

Finally, by including the inductor and possibly other passives, a power module is clearly more expensive than a discrete IC that does not include these components. In this paper, I did a thorough study of the trade-offs between a discrete IC and a power-module design. Providing a third comparison point, the paper looked at two discrete IC designs: one with the same small inductor used in the power module and the other with a larger inductor used on the evaluation module (EVM), which achieves higher efficiency. Figure 2 shows the differences in efficiency, size, height and cost for the example designs.

Figure 2 Overview of Key Trade-offs

When Choosing a Power Module or Discrete Design

Figure 2 Overview of Key Trade-offs

When Choosing a Power Module or Discrete DesignWhich do you prefer: power module or discrete IC?

Additional Resources

- Design your application in minutes with the TPS82085 and WEBENCH Power Designer