SSZTBK1 march 2016 TPD4E05U06

A human-machine interface (HMI) gives people the ability to assess and control industrial automation equipment. HMI devices are often connected to programmable logic controllers (PLCs) and are an essential part of the control structure for the manufacturing of many products we use every day.

HMI solutions need to be very robust to properly function in often hazardous manufacturing environments. They are at particular risk for electrical overstress (EOS) because of the many electrical transients that exist in industrial or manufacturing environments. In this post, I will discuss the standards used to govern devices that protect against aggressive electrical transients and a particular device type often chosen to protect HMI solutions.

The IEC 61000-4-X Electrical Transient Immunity Standard

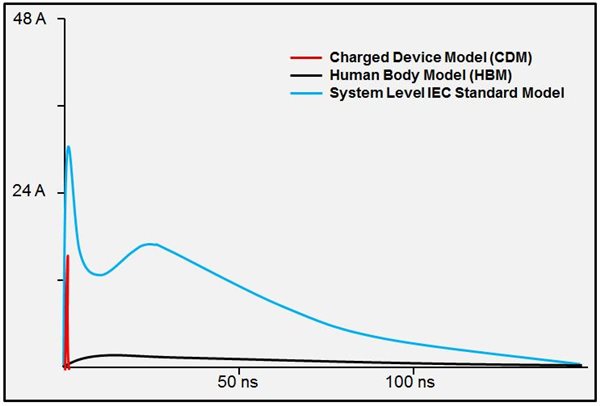

When you look at data sheets for semiconductor devices used in HMI applications (such as Ethernet PHYs and microprocessors), you’ll see human-body model (HBM) and charged-device model (CDM) Electrostatic Discharge (ESD) ratings. The HBM rating provides an indication of the chip’s resilience to ESD damage from human handling, while the CDM rating is related to the chip’s ability to resist ESD damage during automated manufacturing.

Neither HBM nor CDM device ratings address the need for overall system transient immunity. So the International Electrotechnical Commission (IEC) released system-level transient immunity standards to ensure that complete systems, like HMIs, would be protected against EOS. They are:

- IEC 61000-4-2: electrostatic discharge immunity test.

- IEC 61000-4-4: electrical fast transient (EFT) immunity test.

- IEC 61000-4-5: surge immunity test.

Compared to CDM and HBM, the IEC 61000-4-2 standard tests to higher levels of ESD energy; see Figure 1. The IEC 61000-4-4 and IEC 61000-4-5 standards provide an extra layer of transient protection to ensure a robust final product.

Figure 1 ESD Test Comparison

Figure 1 ESD Test ComparisonTransient Voltage Suppressors

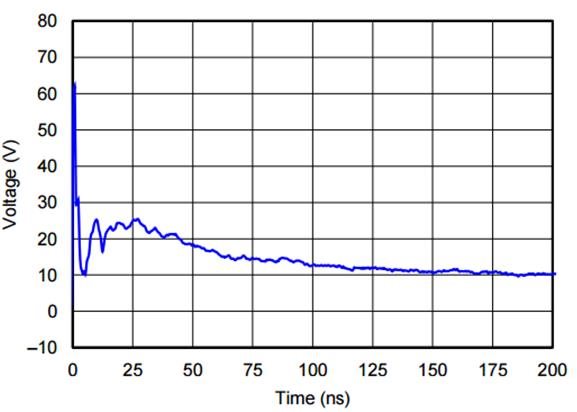

Transient voltage suppressor (TVS) diodes deliver IEC 61000-4-x system-level protection for industrial applications, including HMI. TVS diodes should be placed as close as possible to USB, Ethernet, High-Definition Multimedia Interface (HDMI), RS-232/485, Video Graphics Array (VGA), Liquid Crystal Display (LCD), or touch-screen interfaces because each serve as a gateway that allows damaging electrical transients (ESD, EFT, surge) to enter HMI systems. When a TVS diode detects an electrical transient like ESD, it will begin conducting the current of that high-energy transient to ground instead of allowing it to be transmitted into the system. Figure 2 shows how the TPD4E05U06 responds to a +8kV ESD event. Furthermore, engineers can take advantage of the low capacitance and easy straight-through routing package offered by the TPD4E05U06 for interfaces found in HMI applications (HDMI, Ethernet, LCD and USB).

Figure 2 TPD4E05U06 IEC 61000-4-2 Clamping Voltage, +8kV Contact

Figure 2 TPD4E05U06 IEC 61000-4-2 Clamping Voltage, +8kV ContactTo learn more about Texas Instruments protection devices, visit the ESD protection overview page. The overview page includes additional information about TI protection product families, the ESD by Interface table which recommends champion parts and links to parametric search by clicking “View Products”.

Additional Resources

- Learn more about TI circuit protection devices on the TI ESD protection diodes landing page.

- To learn more about TVS diodes, test setups and layout, check out these application reports: