SSZTBB6 may 2016 DP83848Q-Q1

Innovative automotive technology such as automatic parking, active lane detection and autonomous vehicles, have increased the number of complex in-vehicle systems. The Society of Automotive Engineers created on-board diagnostics II (OBD-II) in order to monitor these systems and properly diagnose them when they are not functioning correctly. The OBD-II port handles diagnostics and emission tests and logs data from sensors; it also flashes the engine control unit (ECU).

OBD-II has been in use since 1996 and has given countless technicians and owners the ability to identify problems that may occur in a car. This is most often seen in the form of a check engine light on the dashboard of a car. The most dominant technology currently used for diagnostics is the controller area network (CAN) bus, but there is an ongoing shift in the industry to employ the use of Ethernet for such applications. The shift is occurring because Ethernet offers bandwidths up to 100 Mbps (see TI’s DP83848Q-Q1, shown in Figure 1).

Figure 1 The DP83848Q-Q1 Will Be Used

for Diagnostics and Will Be Integrated into the OBD-II Port.

Figure 1 The DP83848Q-Q1 Will Be Used

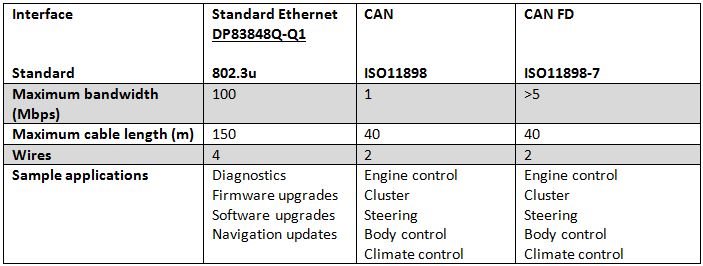

for Diagnostics and Will Be Integrated into the OBD-II Port.The main benefit of using Ethernet within an OBD-II system is that Ethernet operates at 100 times the speed of a CAN bus and 20 times faster than CAN with flexible data rate (CAN-FD). This enables software and firmware upgrades in minutes rather than hours with the increased bandwidth. The longer cable reach also allows for more flexibility in end-of-the-line testing. See the table below for a comparison between Ethernet, CAN and CAN-FD technologies.

|

The Institute of Electrical and Electronics Engineers (IEEE) recently adopted a revolutionary new standard, IEEE 802.3bw, for bidirectional 100Mbps data rates over a single twisted pair. This standard will allow automotive engineers to implement Ethernet into more car applications than ever before due to the increased bandwidth, in conjunction with the weight and cost savings offered by single twisted pair cabling. This is merely the beginning of the rise of automotive Ethernet as more and more applications are added to connected cars, from diagnostics to infotainment, and even including ADAS functionality.

If you have questions about the adoption of Ethernet in ODB-II applications, leave a comment below or visit the TI E2E™ Community Ethernet forum.

Additional Resources

- Increase interface speeds even more with our Gigabit Ethernet PHY family

- Learn more about TI’s entire Ethernet portfolio

- Read the white paper, “Simplify CAN bus implementations with chokeless transceivers” to learn about CAN transceivers with flexible data rate