SSZTB77 june 2016 LM2574 , LM2574HV , LM2575 , LM2576 , LM2576HV , LM2590HV , LM2591HV , LM2592HV , LM2593HV , LM2594 , LM2594HV , LM2595 , LM2596 , LM2597 , LM2597HV , LM2598 , LM2599 , LM2672 , LM2674 , LM2675 , LM2676 , LM2677 , LM5575 , LMR33610 , LMR33620 , LMR33630 , LMR33640 , LMR36510 , LMR36520

This article was co-authored by Harrison Overturf and updated in August 2020.

The most basic definition of reliability is the consistency of the measure. If you can consistently produce the same result under the same conditions, then the product is reliable. Simplicity is also an important factor. Reducing the number of parts in a system reduces the risk of one component malfunctioning and negatively impacting performance. For example, in the auto industry, a major concern is the reliability of the internal combustion engine. The functionality of the engine depends on perfectly timed interactions of hundreds of moving parts, so reliability is very important to ensure that cars run properly for 10+ years. Similarly, in the world of power electronics, most DC/DC converters rely on external components to configure the device and achieve the performance that the customer needs. However, every extra external component needed adds additional risk into the system.

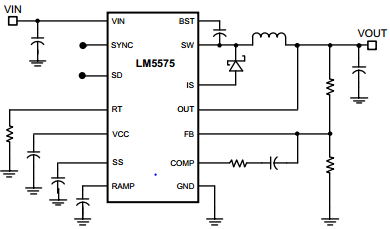

Since reliability and simplicity go hand in hand, it is no surprise that the simplest parts to design also tend to be highly reliable. That is because simpler products have reduced bill-of-material (BOM) counts and integrate as many external components into the chip as possible. A high level of integration has several advantages, including reduced BOM count and cost, reduced board space, reduced design work, and higher reliability. The trade-off of high integration is a loss of flexibility. Converters like the TI LM5575 shown in Figure 1 require 12 or more external components to configure features and optimize the DC/DC regulator design to give the best performance for a particular application. Unless the application has particularly stringent requirements, however, the extra work and risk may not be worth it. Would you rather put in the work to complete a complicated design with 14 external components or buy a simpler product with higher reliability?

Figure 1 LM5575 Schematic

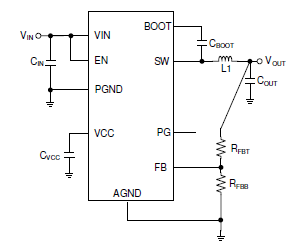

Figure 1 LM5575 SchematicConverters like the LMR33610 SIMPLE SWITCHER®, shown in Figure 2, offer internal compensation networks to achieve low BOM count and increase reliability. Compensation networks are a necessary part of power IC design in order to ensure a stable loop response. Traditionally, power engineers have designed external compensation networks. The advantage of an external compensation network is the flexibility to freely select components and optimize the design to achieve a faster transient response. But designing the compensation is a complex, painstaking process. If you are a power expert with plenty of time, it’s no problem. If you are working under a deadline or do not have the necessary expertise, you may not have the time to properly design an external compensation network. If that’s the case, internal compensation greatly reduces the number of steps and risk in a power IC design. An internal compensation network minimizes the risk of faulty components or a mistake in the design that could negatively affect the end equipment’s performance. It also reduces the time it takes to design the power platform.

Figure 2 LMR33610 Schematic

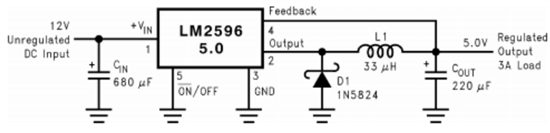

Figure 2 LMR33610 SchematicFixed-output-voltage regulators offer another way to increase reliability. This increased reliability comes at the cost of reduced design flexibility. However, many engineers use buck converters to power 24-V, 12-V, 5-V or 3.3-V rails off a battery. Fixed-output versions at these voltage levels provide several advantages, including decreasing BOM count, increasing reliability, improving the voltage accuracy of the output, and decreasing output noise. For example, in Figure 3, the LM2596 requires only four external components to function.

Figure 3 LM2596 Schematic

Figure 3 LM2596 SchematicIf you’re looking for a reliable device to simplify your power supply design, the LM2576, LM2596, and LM2676 all have low external components counts making them easy to use. For designs that require higher switching frequency, the LMR36510 and LMR33610 (which is pin-to-pin compatible with other SIMPLE SWITCHER converters, like the 36-VIN capable converters like LMR33620, LMR33630 and LMR33640, and the 65-VIN capable converters like LMR36510 and LMR36520) offer compact solutions with low BOM cost. These devices also include some added features such as hiccup short circuit protection and high light load efficiency all within the easy to use HSOIC-8 package.