SSZTB20 july 2016 AM3357 , AM3359

Industrial Ethernet is taking a lead role over the serial-based fieldbus in products for factory and process automation, grid infrastructure and building automation. Industrial Ethernet connects the programmable logic controller (PLC) with field-installed sensors and actuators, input and output modules, and bus couplers and drives.

Unfortunately, a common industrial Ethernet standard has not been defined across product manufacturers; instead, the field is fragmented, with more than 30 standards deployed in factories. Many leading manufacturers have defined a specific industrial Ethernet standard to fit their needs, often derived from one of their existing serial-based fieldbuses.

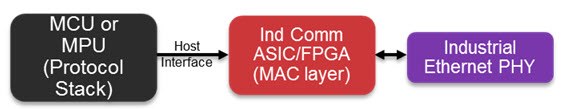

Most industrial Ethernet standards require an individual device solution. Figure 1 illustrates a solution consisting of a microcontroller unit (MCU) or microprocessor unit (MPU) and a separate industrial Ethernet device, the media access controller (MAC). The MAC supports the task of real-time Ethernet frame processing, which is technically referred to as “on-the-fly” or “cut-through” frame processing. Therefore, most industrial Ethernet standards require an application-specific integrated circuit (ASIC) or field-programmable gate array (FPGA) to handle the real-time Ethernet frame processing.

Figure 1 The traditional way to add

industrial Ethernet

Figure 1 The traditional way to add

industrial EthernetAdding one of the industrial Ethernet standards to a product and then certifying the communication interface with certification bodies has its challenges. However, most manufacturers will need to support multiple industrial Ethernet protocols in order to sell their equipment to multiple end-customers using different standards. Building a product that can “speak” two, three or more industrial Ethernet standards adds an additional dimension of complexity to product development. One possible solution to add multiple Ethernet standards to a product is to create separate printed circuit board (PCB) modules for each of the industrial Ethernet standards. You plug one of the modules into the main board at a time. However, there is always a hardware change required to exchange the protocol. This makes the product more complex in terms of handling the bill of materials (BOM) and the need for multiple PCB module production, as well as sourcing multichip solutions.

To solve this challenge, I encourage you to take a look at the TI Sitara™ ARM processor. These application processors have an integrated programmable real-time unit and industrial communication subsystem (PRU-ICSS), which is able to speak multiprotocol industrial Ethernet. Let’s review the key differences and advantages of this solution.

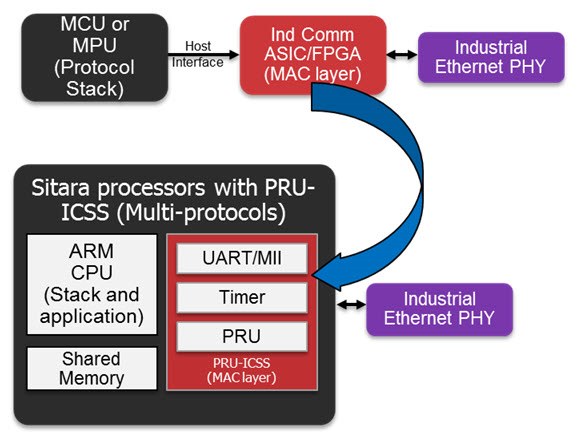

The PRU is a programmable real-time core. It loads industrial Ethernet protocol firmware at device runtime. There are PRU-ICSS protocol firmware releases available for EtherCAT, PROFINET, Sercos III, Ethernet/IP and Ethernet PowerLink. The protocol firmware performs real-time critical tasks such as on-the-fly or cut-through frame processing. Note that these are the real-time critical tasks I previously referred to that operate in an ASIC or FPGA, but now are handled by the PRU-ICSS (see Figure 2).

Figure 2 TI integrates multiprotocol

industrial Ethernet into Sitara processors

Figure 2 TI integrates multiprotocol

industrial Ethernet into Sitara processorsThe PRU-ICSS, together with the scalable and powerful ARM core (Cortex-A8, A9 or A15, depending on the Sitara processor family) enables you to build a single-chip solution for products in factory automation, which can then speak in multiple industrial Ethernet standards through the flexible exchange of PRU-ICSS firmware. The PRU-ICSS solves the problem of multiprotocol support with software, a programmable solution on the PRU-ICSS, instead of hardware like multiple ASICs or an FPGA. A software-based solution has many advantages, including the ability to be upgraded when new protocol standards are released to add new features or entirely new protocols.

In addition to these advantages and the ability to handle the real-time critical industrial Ethernet processing tasks, the PRU-ICSS also:

- Eliminates the need for external ASICs and FPGAs.

- Reduces BOM and PCB space and therefore cost.

- Enables fast I/O data exchange between the ARM processor via an internal high-speed memory bus interface.

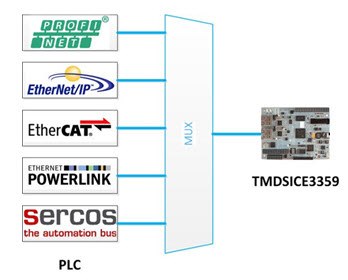

The PRU-ICSS firmware is exchangeable during device runtime. Figure 3 shows the five industrial Ethernet standards most commonly used in factory automation, all of which are supported by firmware from TI for the Sitara device family.

Figure 3 Multiprotocol demonstration

setup – the TMDSICE3359 AM335x processor development platform

“speaks” the top five industrial Ethernet standards

Figure 3 Multiprotocol demonstration

setup – the TMDSICE3359 AM335x processor development platform

“speaks” the top five industrial Ethernet standardsI recently recorded a one-hour webinar on multiprotocol industrial Ethernet with Sitara processors to give you additional information about this topic. You can access the webinar through your myTI login.

Additional Resources:

- To learn more about the top five industrial Ethernet standards, read the industrial Ethernet blog series.

- Get familiar with all industrial communication protocols supported by TI processors.

- Download the Multi-Protocol Industrial Ethernet Detection w/PRU-ICSS for Industrial Automation Reference Design (TIDEP0032).

- Discover the AM3359 processor industrial communications engine development platform.