SSZTAZ8 August 2016 LDC0851 , LDC1614

In my last post, I showed step by step how WEBENCH® Coil Designer can produce the sensor computer-aided design (CAD) files for inductive-sensing applications. This method works well for single-coil inductive sensors such as the LDC1614, but the LDC0851 inductive switch requires two sensors, which can either be side by side or stacked.

With the most recent WEBENCH updates, it is no longer necessary to draw coils by hand; WEBENCH Coil Designer produces coil designs in less than five minutes. Today, I will show you how to design stacked coils in the WEBENCH tool.

What Is the Difference between Stacked and Side-by-side Coils?

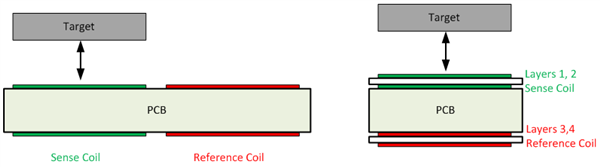

A side-by-side arrangement, as shown in Figure 1, enables the greatest sensitivity and is easily implemented for a two-layer printed circuit board (PCB). Exporting two identical coils from the WEBENCH tool and connecting them on one PCB is a sufficient side-by-side coil implementation.

An alternative arrangement is the stacked-coil arrangement, in which the coils are stacked on top of each other on a four-layer PCB. Placing the sense coil on top ensures that the influence of the target on the sense-coil inductance is always stronger than on the reference-coil inductance. This approach is commonly used for space-constrained proximity-sensing applications such as door open/close detection.

Figure 1 Side-by-side Coil Arrangement (Left) vs. Stacked Coil Arrangement (Right)

Figure 1 Side-by-side Coil Arrangement (Left) vs. Stacked Coil Arrangement (Right)How Do I Use WEBENCH Coil Designer to Design Stacked Coils?

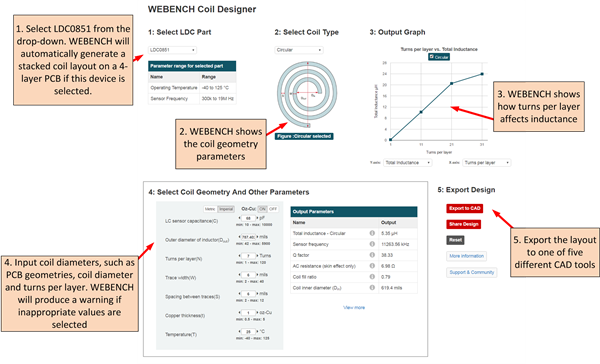

To design a stacked coil with WEBENCH Coil Designer, follow the five steps shown in Figure 2.

Figure 2 Five Steps for Designing a Stacked Coil in WEBENCH Coil Designer

Figure 2 Five Steps for Designing a Stacked Coil in WEBENCH Coil DesignerYou can export the coil to any of these CAD formats:

- Altium Designer.

- Cadence Allegro 16.0-16.6.

- CadSoft EAGLE PCB (v6.4 or newer).

- DesignSpark PCB.

- Mentor Graphics PADS PCB.

I used the default settings, which represent the coil on the LDC0851 evaluation module. This configuration is particularly good for sensing larger targets. Note that if you are sensing the presence of small targets such as a screw head, you should add more turns so that the coil-fill ratio (dIN/dOUT) is less than 0.3.

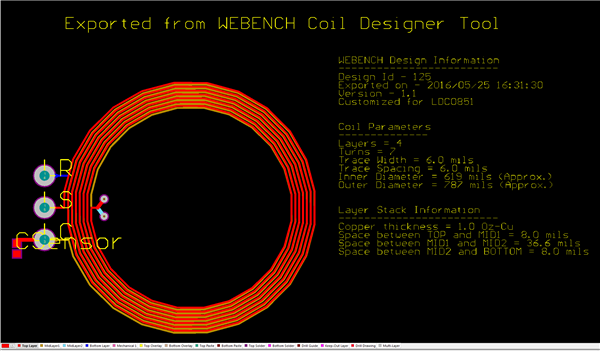

Figure 3 shows the layout in Altium Designer. The Top Layer and MidLayer1 contain the sense coil, while the reference coil spans from MidLayer2 to the Bottom Layer.

Figure 3 The Finished Coil in Altium Designer Format

Figure 3 The Finished Coil in Altium Designer FormatWhere Is the Switching Point?

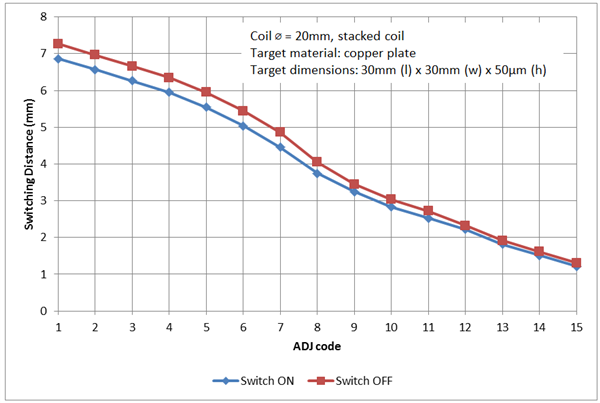

The maximum switching point scales with the coil diameter. You can reduce the switching point down with the ADJ pin to fine-tune the switching distance. For stacked coils, put the LDC0851 in threshold adjust mode. Figure 4 shows the switch-on and switch-off points for a 20mm stacked coil that I designed. The maximum switching distance is about 6.8mm for an ADJ setting of 1 and is scalable down to about 1.2mm for an ADJ setting of 15.

Figure 4 Threshold Set and Release

Points

Figure 4 Threshold Set and Release

PointsDesigning stacked coils for inductive-switch applications doesn’t need to take much time. By following the approach I’ve described in this post, you can design a coil and export it to the PCB CAD tool of your choice in less than five minutes.

Do you find our WEBENCH tools for inductive sensing useful? Are there other WEBENCH tool features that would make your system design with LDCs easier? If so, leave a note in the comments section below.

Additional Resources

- View the LDC0851 data sheet.

- Download the LDC tools spreadsheet, which includes a dedicated tab to configure an LDC0851.

- Read other blogs about inductive sensing.