SSZTAO7 november 2016 CC1350 , LMT70 , TMP007 , TMP103 , TMP112 , TMP114

Today, there are many applications that require accurate and continuous temperature sensing to protect a product or improve system performance. Temperature sensors now have the ability to deliver accurate measurements wirelessly and in real-time thanks to advancements in connectivity technology. In many applications, the ability to monitor and control a system from a remote location is a key requirement. By combining long-range Sub-1 GHz networking with Bluetooth® low energy (2.4 GHz) connectivity opens up a world of possibilities for temperature measurement. Here we will discuss how the use of these technologies together can enhance systems where temperature measurement is critical.

Some Example Applications - Cold Chain Management and Home Automation

- Cold chain management

- Home automation

Cold Chain Management

Home Automation

Building a Dual-band, Temperature Monitoring System

- Using the I2C interface that is directly controller by the ARM® Cortex®-M3 application processor. The I2C module has a dedicated driver library function that is integrated as a part of the TI RTOS (real-time operating system). The I2C software routine used to handle the sensor can be found here on ti.com. This can be used as an example to handle other I2C temperature sensors as well.

- Using the sensor controller on board the CC1350 device. The sensor controller has its own configuration tool called the Sensor Controller Studio that contains sample code for the I2C interface. To access this code, download the Sensor Controller Studio and click on the I2C example on the front page.

Using the sensor controller will give the lowest current consumption. However, in most use cases, the temperature sensor is read out very infrequently (interval of ten seconds or more) – in these cases the difference with respect to average current consumption is negligible between the ARM Cortex-M3 and the sensor controller. A temperature read of every 10s can easily be designed to consume less than 1µA in total current consumption – including the stand-by (32kHz) sleep current consumption.

Connecting an Analog Temperature Sensor to a Dual-band Wireless MCU

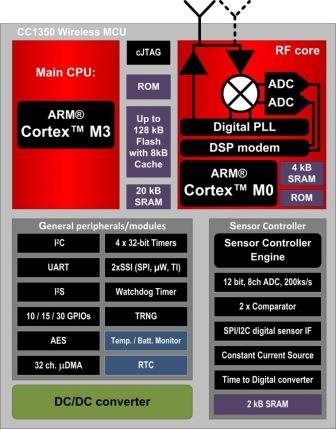

Figure 1 Block Diagram of the SimpleLink Dual-band CC1350 Wireless MCU

Figure 1 Block Diagram of the SimpleLink Dual-band CC1350 Wireless MCUAdditional Resources:

- Learn more about TI’s sensor portfolio.

- Choose your temperature sensor.

- Get started with the SimpleLink dual-band CC1350 wireless MCU LaunchPad™ kit

- Download the TI 15.4-Stack, a Sub-1 GHz star network protocol based on IEEE 802.15.4g PHY.

- Want to learn more about how you can use the CC1350 wireless MCU? Read other parts of this technical article series: