SSZTAI5 december 2016

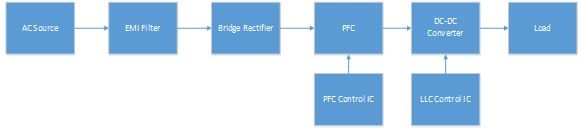

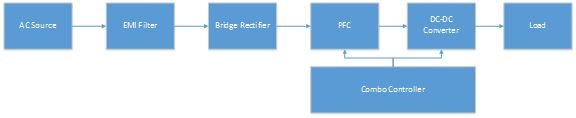

If you have ever listened in on typical hallway conversations in a power-supply design company, it’s likely you have heard a spirited debate on whether the right way to design a >75W power supply involves the architecture shown in Figure 1 or Figure 2. The power-supply components in both cases are exactly the same; the only difference is the controller.

Figure 1 Discrete Controller IC-based AC/DC Design

Figure 1 Discrete Controller IC-based AC/DC Design Figure 2 Combo Controller IC-based AC/DC Design

Figure 2 Combo Controller IC-based AC/DC DesignTexas Instruments has supporters on both sides of the debate, and a track record of products to back both solutions.

Notwithstanding the length and breadth of TI’s product portfolio in the combination or “combo” controller space and the ability to get more features within the same solutions, I still subscribe to the argument that in the long run, a stand-alone power factor correction (PFC) controller followed by a stand-alone DC/DC converter offers an unparalleled set of advantages for engineers designing a wide range of applications, especially in the current cost-conscious consumer space.

Layout

The following image displays the form-factor-compliant High Efficiency 350W AC/DC Power Supply Reference Design for industrial power supplies. Here is a space-constrained design that looks more like downtown Dallas than a low-cost two-layer PCB layout. Having a single combo controller to which signals are routed is no different than wanting a single massive parking lot catering to the whole of Manhattan fed by single-lane alleys ... good luck getting in and out.

The uniqueness of power-supply requirements and the one-size-fits-all nature of combo controllers fundamentally do not jive. Some power supplies are constant current, some are constant voltage, some require high total harmonic distortion (THD), some require low standby, some are meant to be fixed load – but almost none need all of these things. Using such a solution for your application can become a bit of overkill."Some power supplies are more equal than others"

As long as the diversity of the power supplies continues to exist, there will always be logical reasons where a 2-IC solution may be a much better fit for your applications and the coffee pot in the hallway nearest to my desk will continue to get its broad patronage…

Discover the controllers that TI is currently offers to target these applications.