SSZTA42 June 2017 TMP302 , TMP302-Q1 , TPS65981

Over the past decade, portable devices like tablets and smartphones have become a more integral part of our daily life. We depend on them to stay in touch with friends and family, get work done and provide directions to unknown places. Personal electronics manufacturers have focused on delivering portable devices that last longer on a single charge and take less time to charge to support our busy lifestyle.

The most common port for portable electronics is USB, and USB protocols have evolved to transfer data faster and deliver more power. For example, the USB 2.0 standard downstream port (SDP) has been around for a long time; it can transfer data and provide up to 500mA of charge current. However, the most recent USB Power Delivery (PD) protocol enables up to 5A and 20V (100W) of power. This higher power output means that USB PD ports can quickly charge small electronics and efficiently charge larger electronics such as laptops. Additionally, automotive manufacturers are installing USB ports in automotive head units, media hubs and rear-seat entertainment consoles.

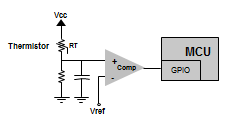

With the USB PD port providing up to 100W of power, there is a greater need to ensure proper thermal management. An overheating USB PD port can damage critical components like the USB charge controller, or may become unsafe to touch. Personal electronics and automotive designers can help protect against overheating by leveraging a USB PD charge controller with a built-in thermal shutdown. For example, the TPS65981 will shut down the power path when the die temperature exceeds 135°C, thus helping keep the USB PD charge controller from burning up and permanently disabling the USB port. However, the temperature-sensing element inside the USB PD controller is targeted at measuring its own die temperature and is susceptible to errors caused by self-heating. Many designers, specifically automotive designers, will implement the external circuit shown in Figure 1 to have tighter control over the overall USB system temperature.

Figure 1 Thermistor and Comparator

Temperature Circuit

Figure 1 Thermistor and Comparator

Temperature CircuitThe thermistor and comparator in Figure 1 create a switched output that will notify the microcontroller (MCU) when exceeding a pre-determined temperature threshold. The most commonly used thermistor for this type of external temperature protection is the negative temperature coefficient (NTC) thermistor. Most NTCs have their resistance specified at 25°C, a nonlinear response as temperature increases and low sensitivity at high temperatures. It is possible to improve NTC performance by performing thermistor calibration, but that will increase the overall system cost.

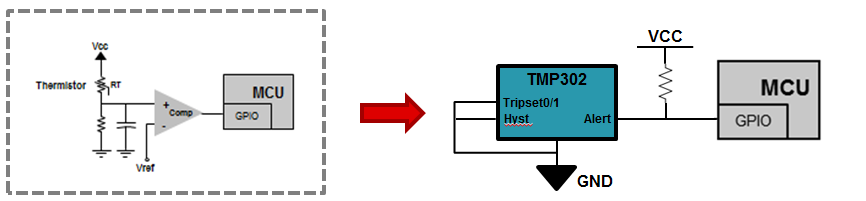

Semiconductor-based temperature sensors can now replace discrete temperature circuits like the one shown in Figure 1. For example, the TMP302 and automotive-qualified TMP302-Q1 are both temperature switch products that will send an alert signal when a pre-determined temperature threshold is exceeded. This behavior enables you to replace the thermistor and comparator temperature circuit with temperature switches like the TMP302; see Figure 2. Additionally, the TMP302-Q1 has a more linear response over a wide temperature range for improved accuracy and does not require any device-level calibration. The TI temperature switch portfolio also includes more advanced features like selectable temperature hysteresis and dual threshold detection.

Figure 2 Temperature Switch IC vs.

Discrete Temperature Switch

Figure 2 Temperature Switch IC vs.

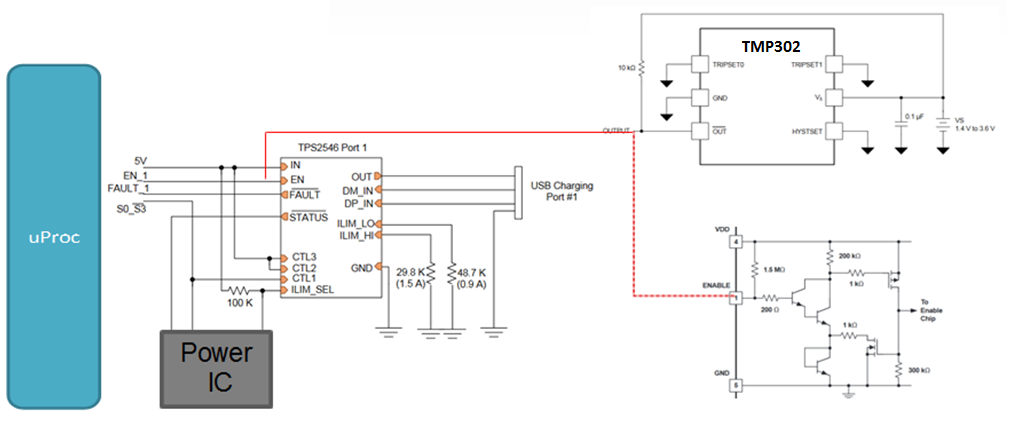

Discrete Temperature SwitchTemperature switches with an active low alert signal, like the TMP302 and TMP302-Q1, enable the implementation of USB PD port overtemperature protection without the need for an MCU. This is accomplished by tying the active low alert/temperature switch output to the enable of a USB PD charger like the TPS65981. During normal operation, the temperature switch alert signal will be high, which will keep the TPS65981 enabled. When the temperature switch detects an overtemperature condition, it will pull the alert signal low, which will disable the USB charge controller; see Figure 3.

Figure 3 USB Overtemperature Protection

without an MCU

Figure 3 USB Overtemperature Protection

without an MCUUSB PD ports provide a great way to quickly charge small portable electronics and even replace the charging cables currently used for laptops. With the increased power density and small solution size, concerns about proper thermal management are valid. TI offers several solutions that enable you to fully leverage the power-delivery capabilities of USB PD and maintain a safe operating temperature for both the system and end user.

Additional Resources

- Check out TI’s temperature switch solutions.

- Learn more about temperature sensor integrated circuits and their advantages compared to thermistors.

- View the entire temperature sensor portfolio.