SSZT988 august 2017 DRV10983-Q1

Intelligent integrated motor drivers and brushless DC (BLDC) motors can both help electric vehicles and next-generation automobiles become more attractive, viable, and reliable.

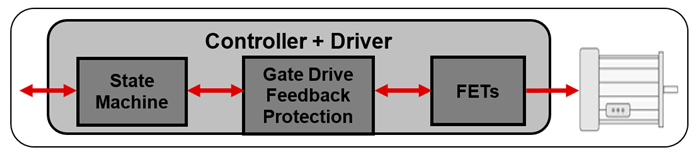

Integrated motor drivers combine everything required to drive a motor, such as field-effect transistors (FETs), gate drivers, and state machines, as shown in Figure 1. Integration prevents long routing of wires from the electronic control unit (ECU) to the motor and has additional advantages of smaller printed circuit board (PCB) size and overall system cost.

The advantages that BLDC motors provide in automotive applications include efficiency, compact size, longer motor and battery life, quieter in-cabin experience, and better electromagnetic interference (EMI) performance.

Figure 1 Intelligent Integrated BLDC Motor Driver

Figure 1 Intelligent Integrated BLDC Motor DriverIn this integrated intelligence blog series, I will describe the different performance requirements for BLDC motors and what makes TI integrated motor drivers “intelligent.” In this first installment, I will elaborate on EMI management in a BLDC system for automotive applications.

BLDC motors are driven at high switching frequency in the range of 10-100kHz. At this high frequency, the combination of high dv/dt and parasitic inductance causes high-frequency ringing on the switching node. This ringing emits high-frequency noise that can interfere with other components in the car.

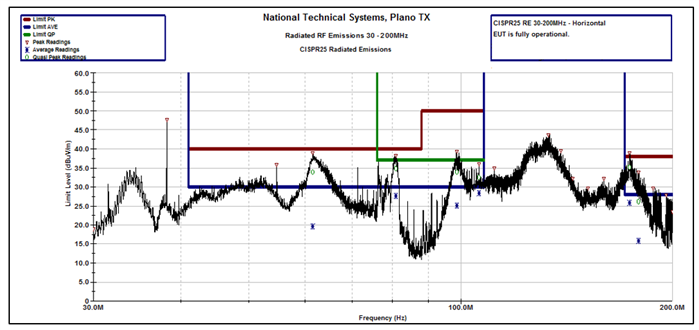

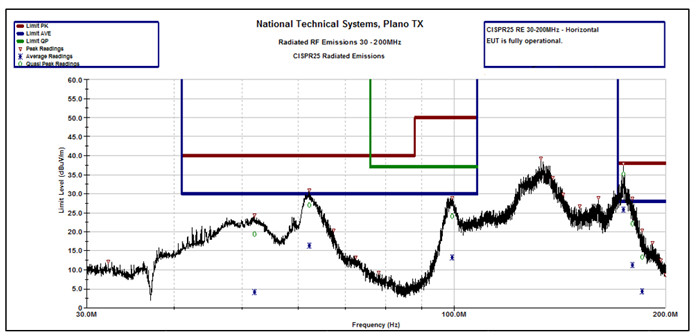

Adjusting the slew rate of the applied voltage can help reduce interference caused by ringing, as shown in Figure 2 and Figure 3. In a discrete system, adjusting the gate-driver resistor modifies the slew rate of the voltage. You have to change the resistor value manually and select an optimal value based on the test results. The process of manually changing the resistor is tedious and requires multiple iterations of PCBs, which increase both overall size and complexity.

In the case of integrated drivers like the DRV10983-Q1, the gate resistor is not accessible and cannot be changed – and that’s not a bad thing. For example, slew-rate control is integrated in the DRV10983-Q1; you can easily change this slew rate by changing the register value, which speeds up the whole exercise of testing modules for EMI.

Figure 2 Sample EMI Measurement with a

Slew Rate of 120V/µs for the DRV10983-Q1 and a BLDC Motor

Figure 2 Sample EMI Measurement with a

Slew Rate of 120V/µs for the DRV10983-Q1 and a BLDC Motor Figure 3 Sample EMI Measurement with a

Slew Rate of 35V/µs for the DRV10983-Q1 and a BLDC Motor

Figure 3 Sample EMI Measurement with a

Slew Rate of 35V/µs for the DRV10983-Q1 and a BLDC MotorAnother way to improve EMI performance is by changing the pulse-width modulation (PWM) switching frequency. The PWM switching frequency has an effect on ringing. In case of integrated drivers, this PWM frequency can be changed by configuring register. For example, the DRV10983-Q1 has two frequencies (25kHz and 50kHz) to choose from.

One common technique used to reduce EMI is dithering the main clock frequency. Dithering reduces the amplitude of peak frequency by spreading it across the spectrum.

By using motor drivers with fully integrated features such as slew-rate control, changeable PWM switching frequency and dithering, you can reduce the number of external components for filtering. This saves system costs, board space, and – most importantly – the amount of time it takes to figure out emission sources and the effort of having to redesign boards.

In future blogs, I will discuss startup reliability, initial position detection, anti-voltage surge, resynchronization while a motor is spinning in opposite or same direction, sinusoidal commutation and many other integrated features that make motor drivers intelligent.

Additional Resources

- Download the DRV10983-Q1 data sheet.

- Start spinning those BLDC motors with the DRV10983-Q1 evaluation module.

- Watch a video with advice how to quickly start up the DRV10983-Q1 BLDC motor driver EVM.

- Explore other training videos on a variety of topics that help you design with motor drivers.

- Read part two and three of this blog series.