SSZT968 september 2017 ISOW7841

Some parts of a circuit work best when they can be forgotten. Designing distributed intelligence for control of sensing and actuation in noisy environments with our new isolation process is a great example.

Circuit or galvanic isolation physically separates two sides of a circuit to keep direct current (DC) and unwanted alternate current (AC) signals from passing through. This accomplishes a variety of clean-up tasks, but in general these fall into two groups: signal isolation, which prevents noise from corrupting digital signals, and power isolation, which prevents high-voltage surges and spikes from damaging circuitry. Both types of isolation work perfectly when they protect so quietly and effectively that they can be forgotten.

All sensitive circuitry needs isolation to protect it, but the price has traditionally been a big investment in space. Today, though, the trend in factories, automobiles, medical equipment, test and measurement, and a variety of other systems is to distribute control intelligence nearer to the signal source. System designers need smaller isolators to help them distribute signal processing closer to where it is needed for signal accuracy and control response. And that’s exactly what TI has given them with our new isolation process technology.

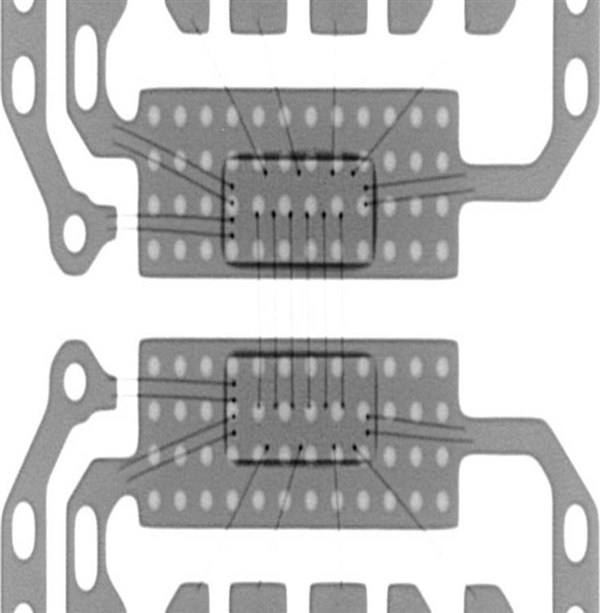

With outstanding isolation protection, our new signal isolation process delivers outstanding isolating protection, integrated in a space-saving package (Figure 1). It includes protective pass-through of high-voltage and high-frequency signaling, delivering increased reliability, shock protection and reinforced isolation equal to two levels of basic isolation in a single package. Products based on this process provide a number of benefits, including smaller board space, improved signal integrity, and immunity in industrial environments -- which also improves safety for human operators.

Figure 1 High Voltage Isolation

Multi-chip Module

Figure 1 High Voltage Isolation

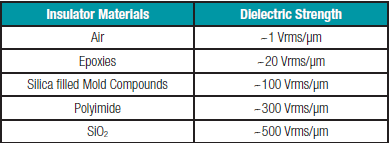

Multi-chip ModuleTo achieve its benefits, the process technology integrates a pair of on-chip capacitors with silicon-dioxide as the dielectric. SiO2, the basic insulator used in all chips, has an exceptionally high dielectric strength equivalent to 500 times that of air, making it an outstanding signal isolator (Figure 2). The advantages of high isolation strength, plus the ability to integrate isolating capacitors on the same chip with other functions, make capacitive signal isolation preferable to alternatives, such as optical signal isolation

Figure 2 The Dielectric Strength of Silicon Dioxide Make It an Excellent Choice for HV Isolation.

Figure 2 The Dielectric Strength of Silicon Dioxide Make It an Excellent Choice for HV Isolation.System developers using TI products based on the process, such as the recently announced ISOW7841, can now avoid headaches associated with high-voltage isolated power supply design and concentrate on value-added areas of their products and speed through certification procedures. Extensive testing was completed on the new process to meet or exceed multiple component-level, system- and end-equipment standards. This includes stressors at various voltages, along with surge testing to enable process quality and reliability for TI products targeted at a range of applications.

Additional Resources

- Read more about signal isolation quality and reliability in our technical brief here.