SSZT921 october 2017 TIC10024-Q1 , TIC12400-Q1

Electronics in vehicles are taking on more and more functions (safety, driver assistance, more driver information) and the demand for greater electronics content overall continues to accelerate. As features related to comfort, safety, equipment and a customized riding experience increase almost daily, so too do the requirements of the vehicle’s electrical system.

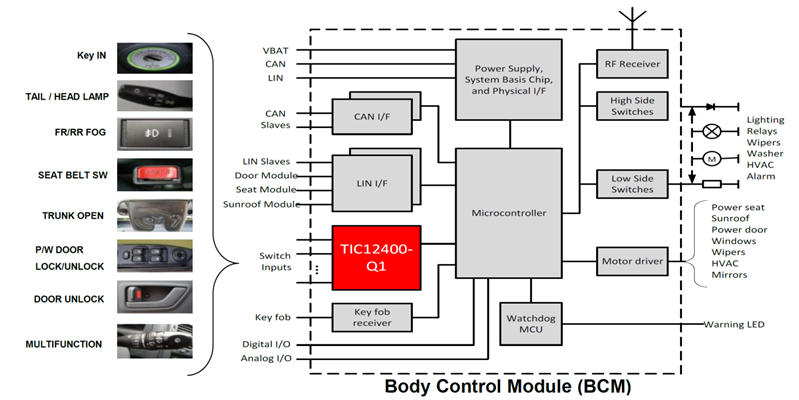

Body control modules (BCMs) coordinate different vehicle functions within a car through the use of signals. They manage numerous vehicle functions, including but not limited to door locks, chime control, interior and exterior lights, security functions, wipers, turn indicators and power management. Tied into the electronics architecture of the vehicle, BCMs reduce the number of plug-in connections and cable harnesses required while offering maximum reliability and economy.

As the demand for increased functionality in BCMs has grown, the amount of cable harnesses has increased as well. For example, according to Kiyotsugu Oba in “Wiring Harnesses for Next Generation Automobiles,” the gross weight of the wiring harness using a conventional electric wire today is about 30kg/car for a compact car, compared to only a few kilograms for a car back in the 1970s. BCMs play a deciding role in cost, as they can reduce the amount of wiring within a vehicle by providing interfaces for bus systems. Around 80% of a product’s budget is decided at the engineering bill-of-materials (BOM) stage – that is, in early development.

Current BCM Market Trends

The market trend is centralization. Centralized architectures have fewer modules with more functionality than decentralized architectures. The benefits of centralized architectures include simpler networking, more cost-effectiveness and an optimized number of electronic control units (ECUs), which in turn reduce harness weight. Reduced weight leads to lower manufacturing costs as well as increased fuel efficiency, a win-win solution for both carmakers and car owners.

However, in light of this trend, centralized architectures today are causing the microcontroller (MCU) to run out of inputs/outputs (I/Os) to connect to the switches and sensors in the car. Complex design architectures are required to connect 60-120 switches to a central BCM. One way to address this problem is to add more discrete components to enable more I/Os. Unfortunately, this only transfers mechanical cost savings from the reduced wiring to additional electrical costs, because the board design now needs more components.

Is There Another Way to Solve This Problem?

One option is to use an integrated multi-switch detection interface solution such as TI’s TIC12400-Q1 or TIC10024-Q1 devices. These devices are part of a family of advanced contact monitors, also known as multiple switch detection interface (MSDI) products, designed to detect the closing and opening action of 24 to 56 switch contacts (Figure 1).

Figure 1 BCM implementation with the

TIC12400-Q1

Figure 1 BCM implementation with the

TIC12400-Q1An MSDI device detects the status of external switches with the use of integrated analog-to-digital converters (ADCs)/comparators and reports the switch status to the MCU after detection. The major difference between the TIC10024-Q1 and TIC12400-Q1 is that the TIC12400-Q1 has a switch-matrix polling feature and an integrated ADC, which means that it can handle analog and multi-threshold inputs.

All of these features not only provide system cost savings, but also offer design flexibility for customizable BCMs – a decisive market advantage.

BOM Savings and Board-size Reduction

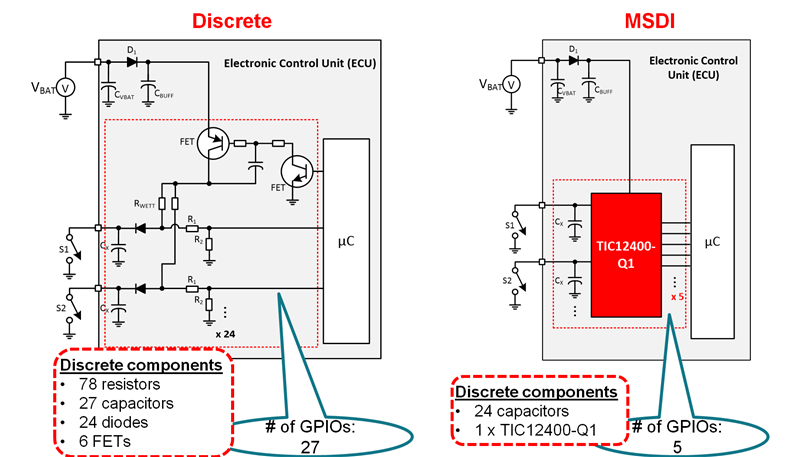

Devices like the TIC10024-Q1 and TIC12400-Q1 enable you to eliminate as many as 120 discrete components; see Figure 2.

Figure 2 TIC12400-Q1 vs. a discrete

implementation

Figure 2 TIC12400-Q1 vs. a discrete

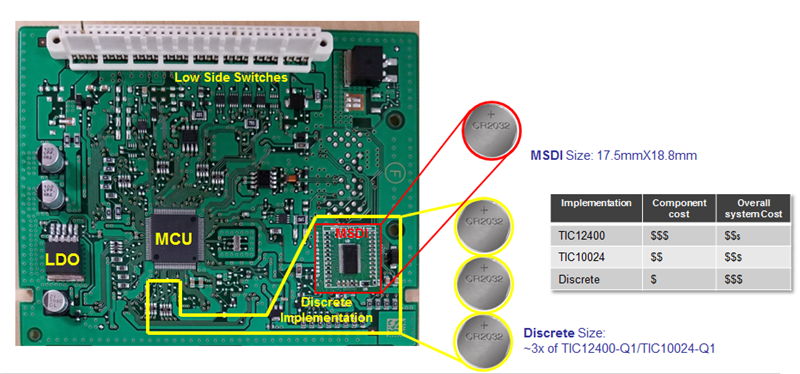

implementationTIC10024-Q1 and TIC12400-Q1 devices also include integrated electrostatic discharge (ESD) protection (±8kV), reverse-battery protection and transient pulse protection. The elimination of external protection components further reduces both BOM cost and board size. The reduced hardware and software complexity also facilitates increased reliability, while scalability enables usage across low-, mid- and high-tier platforms (see Figure 3).

Figure 3 A discrete solution vs. an

MSDI device

Figure 3 A discrete solution vs. an

MSDI deviceMSDI devices feature smart, integrated features to fit perfectly into the current BCM trend and help integrate comfort electronics without breaking the bank.

Additional Resources

- To read more about BCM design and industry trends, see “The multi-switch detection interface: integrated features for smaller, more efficient designs”

- Check out the Automotive Multi-Switch Interface Reference Design

- Watch the TIC12400-Q1 in action.

- Learn more about Automotive gateways: the bridge between communication domains