SSZT864 december 2017 BQ25100 , BQ25120A

Biosensors are devices that monitor various biological processes and convert the results into an electrical signal to be processed and interpreted by doctors and researchers. There are a wide range of biosensors available today, from blood glucose monitors, to water chemical detectors, to pregnancy tests. With the miniaturization of electrical components, medical biosensors have gotten smaller and smaller, and the next big trend is to make them wearable. As wearable devices, patients will have maximum mobility to go about their lives while the portable sensors non-invasively gather data to send to doctors. Patients and physicians can agree that the less time spent in the hospital, the better.

“The wearable technology market is expected to rise from $20 billion in 2015 to close to $70 billion in 2025, led by the health care sector” (via The National Center for Biotechnology Information)

The breadth of up-and-coming wearable biosensors is astonishing. There will soon be smart clothing that can prevent bedsores by providing mild shocks to the body to increase blood flow, shoes that can correct abnormal walking patterns, T-shirts that measure stress via breathing patterns and heart activity, and even socks that can monitor an infant’s health and send updates to the parent’s smartphone.

A lot of wearable health monitoring devices available in the market today are completely disposable or are using batteries that need to be replaced. However, they are becoming more power-hungry due to their connection to smart devices, and disposable batteries may not be sufficient. This is a major cause to switch to rechargeable batteries. As the devices continue to evolve and transition to rechargeable batteries, this could be a big opportunity for linear chargers. The embedded rechargeable designs will allow wearable biosensors to be as compact and convenient for the user as possible. They will typically use low capacity batteries, requiring precise control over current during the charge cycle, to ensure that the battery is as fully charged as possible.

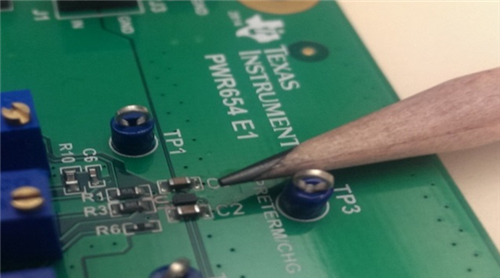

Figure 1 TI’s smallest linear charger

compared to a pencil tip

Figure 1 TI’s smallest linear charger

compared to a pencil tipThe benefit of wearable devices comes from their ability to work around the clock. The more intrusive, bulky, and constant need for recharging the less likely the user will wear it. Thin light devices that require minimal attention will be more popular in the market. Thus the needs for small solution size that can maximize battery life and run-time are an important requirement for the battery chargers in these applications. Figure 1 shows the bq25100 who’s entire solution size is 2.1 mm x 2.2 mm; perfect for a solution that would need to fit on a baby’s foot!

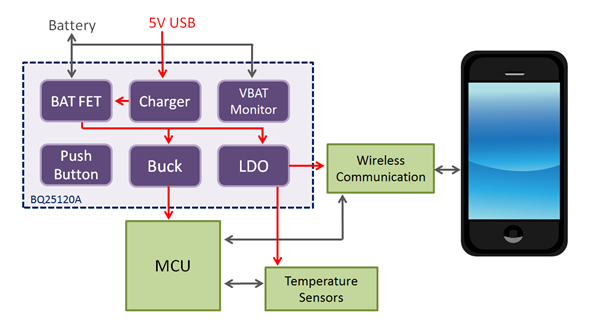

The ability to integrate other components needed to run the system can also shrink your solutions size and reduce the bill of materials. Power management devices like DC/DC converters are a natural component to integrate with the charger as they are need to power other devices in the system. Figure 3 is an example of block diagram for a temperature sensing patch application. The patch is used instead of a thermometer to monitor the temperature of a child or sick person, and then send data to a smart device. The system requires multiple power rails, stepped down from the battery voltage. The bq25120A integrates these six components needed into one device to reduce overall solution size allowing it to fit into a small space.

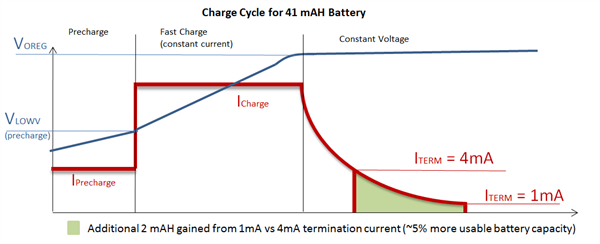

Figure 2 Lithium-ion charging

profile

Figure 2 Lithium-ion charging

profileThe accuracy of charge current relates to the amount of capacity restored back into the battery between each recharge cycle. ITerm in Figure 2 is referring to the current charging terminates at once the battery reaches its full voltage. Terminating charging at 1mA restores an additional 5% capacity to the battery allowing for a longer run time between charges vs. terminating charge at 4mA. The Iq, or the current required by the IC with no load also plays into the battery run time of the device. The less current needed to run the battery charger the more that can be used to run the system. The bq25100 has a leakage current of only 75 nA, which is negligible compared to the self-discharge rate of the battery cell.

Power path is another desirable functionally of charger ICs. It allows the capability of charging the battery while simultaneously powering the system; meaning you can still use your wearable while it is charging. This is a function when pairing these applications with energy harvesting solutions that allow charging while you are still wearing your device, instead of having to remove it to charge through a wire.

Figure 3 Temperature Sensing Patch

Block Diagram

Figure 3 Temperature Sensing Patch

Block DiagramWhen designing for your next biosensor application, consider the linear charging careabouts we talked about today. Features such as rechargeable batteries, compact devices, advanced device integration and power path are all key features. Whether the next wearable biosensor is a hat that monitors depression, or a onesie that helps premature babies, incorporate the features listed above for an intelligent and compact design.