SSZT762 march 2018 BQ24610 , BQ24725A , BQ24773

As technology continues to boom, interconnectivity between devices enables the rapid growth of automated homes. The development of the vacuum robot came about as a result of the convenience of manipulating home equipment through wireless connectivity and remote accessibility.

A vacuum robot eliminates the need for manual floor cleaning by setting schedules to ensure a consistently clean home. In addition to convenience and time savings, these compact vacuum robots – unlike traditional, hefty vacuums – relieve the strain of running a vacuum by easily reaching tough nooks and crannies associated with furniture, walls and corners.

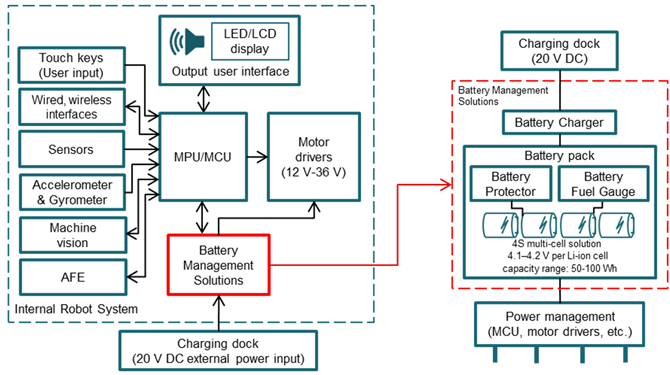

To maximize the floor space cleaned, a vacuum robot must optimize its running time. Thus, a battery-charging solution requires astute consideration in vacuum robot design. Taking an input voltage of approximately 19-20V from a charging dock, most vacuum robots on the market employ rechargeable four-cell lithium-ion (Li-ion) batteries to power their systems. Extending the run time of these batteries and cutting battery costs requires efficient utilization of the battery pack to its fullest capacity. Figure 2 illustrates the vacuum robot system and highlights its battery-management solutions.

Figure 1 Vacuum Robot System Power

Diagrams

Figure 1 Vacuum Robot System Power

DiagramsYou can implement the charging circuit in several ways. The discrete solution uses a simple DC/DC converter to charge the battery. The system’s microcontroller (MCU) mimics a CC-CV charging curve by controlling the on/off switching of the MOSFETs. While the discrete solution may be inexpensive, its inaccurate charge voltage, low switching frequency and lack of built-in battery protections contribute to additional costs and poorer performance than a charger integrated circuit (IC).

Alternatively, charger IC solutions offer high charge voltage accuracies, high switching frequencies and enhanced battery protections. While some designers may choose a discrete solution with a lower cost than the charger IC solution, the benefits of a charger IC impressively outweigh the price difference.

Vacuum robots on the market vary in run time, ranging from about 60 to 150 minutes. Maximizing the amount of cleaned surface area relies on the robot’s operational period, making optimal run time a key selling point for consumers; just several extra minutes could make the difference between an entirely clean and partially dirty home.

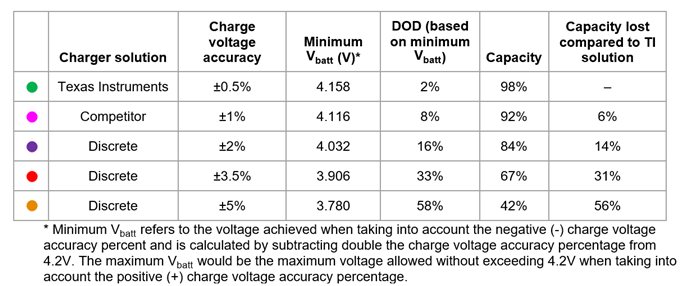

TI’s charger IC such as the bq24725A or bq24610 offers a high-accuracy charge voltage of ±0.5% compared to a low-cost DC/DC converter charge voltage accuracy of ±5%. Due to the small ±0.5% charge voltage accuracy, this charger IC maximizes battery capacity, which ultimately extends the robot’s run time.

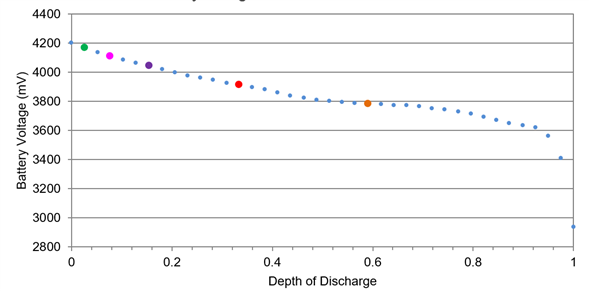

Figure 2 describes the battery voltage versus the depth of discharge (DOD) of a 4.2 Li-ion battery at room temperature. Based on the charge voltage accuracies of the charger IC and several discrete solutions, the data maps several DOD points to battery voltages, which translate to run time. As shown in Figure 2 and its associated data in Figure 3, the TI charger IC solution significantly maximizes capacity over discrete charging solutions.

Figure 2 Li-ion DOD versus Battery

Voltage

Figure 2 Li-ion DOD versus Battery

Voltage Figure 3 Charge Voltage Accuracy Mapped

to Battery Capacity

Figure 3 Charge Voltage Accuracy Mapped

to Battery CapacityBattery capacity ultimately translates to device run time and the cost difference of batteries with a certain run-time goal. For example, take a vacuum robot that uses a TI charger IC solution with ±0.5% charge voltage accuracy that runs for 120 minutes. The same vacuum robot using a DC/DC converter as a discrete solution with a charge voltage accuracy of ±5% would only run for 55 minutes. Therefore, the loss in capacity due to a less accurate charge voltage, as shown in Figure 3, significantly diminishes the run time of the robot.

From a monetary standpoint, a battery pack for this application costs about $20. The 56% capacity lost in this example requires you to purchase $11 more in capacity. This extra 65 minutes of run time would allow the robot to clean several additional rooms, and the cost savings due to maximized capacity quantifies the value of using a charger IC solution.

Charger IC solutions yield high switching frequencies and in turn require small, low-cost inductors. For example, TI’s bq24725A, with a switching frequency of 750kHz, typically uses a 4.7µH inductor sized at 28mm2. Alternatively, a discrete solution with a switching frequency of only 50kHz requires a larger, 75µH or greater inductor covering about 113mm2 of board space. Along with saving solution size, the charger IC’s inductor is roughly two times less expensive than the discrete solution’s inductor, depending on inductor choice.

From a design perspective, a charger IC advantageously offers a complete, sophisticated suite of battery safety features, including input overcurrent, charge overcurrent, battery overvoltage, thermal shutdown, battery shorted to ground, inductor short and field-effect transistor (FET) short protections. On the other hand, a discrete solution would have to use its MCU to implement battery protections, and damage could occur to the battery by the time the MCU detects faults due to its slow response times. Therefore, a charger IC protects the battery in any worst-case scenarios while eliminating the need for you to create your own battery protections.

For additional design flexibility, the TI multicell switching charger portfolio provides options for stand-alone and host-controlled topologies. A stand-alone charger such as the bq24610 controls voltage and current limits with external circuitry elements, facilitating simple implementation. A host-controlled charger such as the bq24725A or bq24773 uses I2C or SMBus to program the limits, saving bill-of-materials cost by employing the calculating power of the system’s already-existing MCU.

A charger IC offers a myriad of advantages over common discrete charging solutions for vacuum robots. Although a discrete solution may be more economical initially, a charger IC solution provides a significantly longer run time, system cost savings and a simpler design implementation than the discrete alternative. Ultimately, the benefits of the complete charger IC solution outweigh the initial cost savings of the discrete charging solution.

Additional resources:

- Find resources and reference designs for vacuum robots here.

- Explore high efficiency battery charger ICs like bq24725A, bq24773 or bq24610

- Don’t forget to consider battery capacity indicators as well. Read this blog for advice on fuel gauges.

- Read the white paper, "Achieving increased functionality and efficiency in vacuum robots."