SSZT746 april 2018 TPS92610-Q1

Auto manufacturers are using light-emitting diodes (LEDs) beyond the traditional front, rear, day-running, stop and turn lights to make their vehicles stand out in the market. LEDs are now appearing in side markers, license plates, brand logos, welcome lights, and ambient lights.

To drive these LEDs, you must consider:

- The accuracy of the current so that the homogeneity of the LEDs are much better.

- The changing brightness of the LEDs, thus requiring some kind of dimming.

- The diagnosis and protection of the LED open/short circuit, as well as thermal protection, since safety is always a key concern in automobiles.

- How to improve energy efficiency.

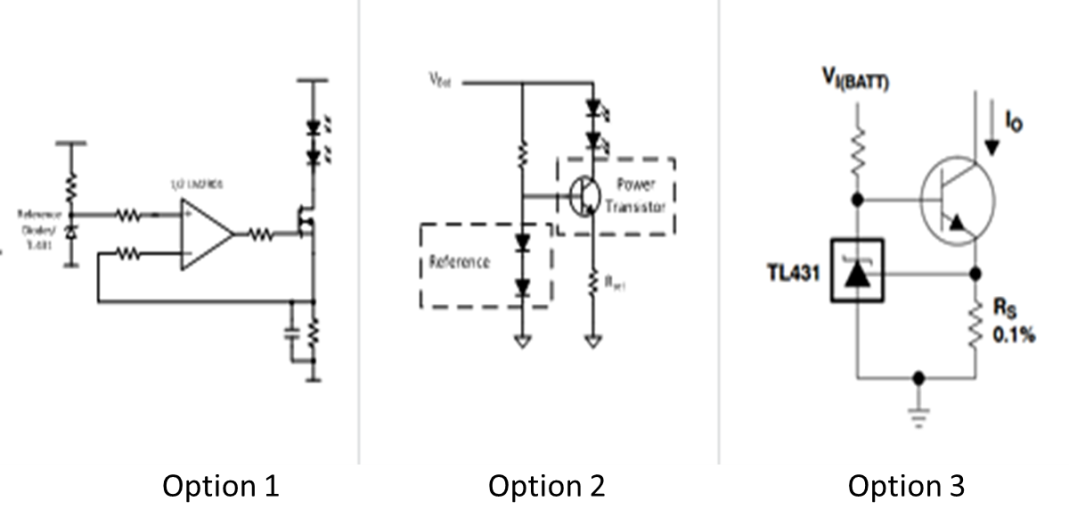

LEDs have traditionally been driven by discrete solutions. Figure 1 shows three typical options: an operational amplifier (op amp) (option 1), a bipolar configuration with the power directly connected to the car battery (option 2) or some type of shunt regulation (option 3).

Figure 1 Typical Discrete Solutions to

Drive LED

Figure 1 Typical Discrete Solutions to

Drive LEDLet’s take a look at option 1 first, an op amp driven from the low side. An op amp enables you to achieve relatively high accuracy (<10%) and dimmable LEDs are also possible. With this solution, however, it’s difficult to achieve the diagnostics for LED open and short circuits. And the dropout voltage is as high as 1V, which is not very energy-efficient.

Option 2 is also popular and consists of diodes and a N-type P-type N type (NPN) transistor. This solution is simple and cost-effective, but the accuracy is only about 20%, which is far from enough. The dropout voltage could be as high as 1.2V, making this solution’s efficiency even lower compared to option 1. Again, no diagnostics are available for LED open and short circuits, and no pulse-width modulation (PWM) dimming is available. This solution is really too old for today’s designs.

Option 3 is popular in applications that require very high output accuracy (<5%). The dropout voltage is extremely high (up to 3V). No diagnostics or PWM dimming are available for this solution; thus, adoption of this option is narrow and the trade-offs are huge.

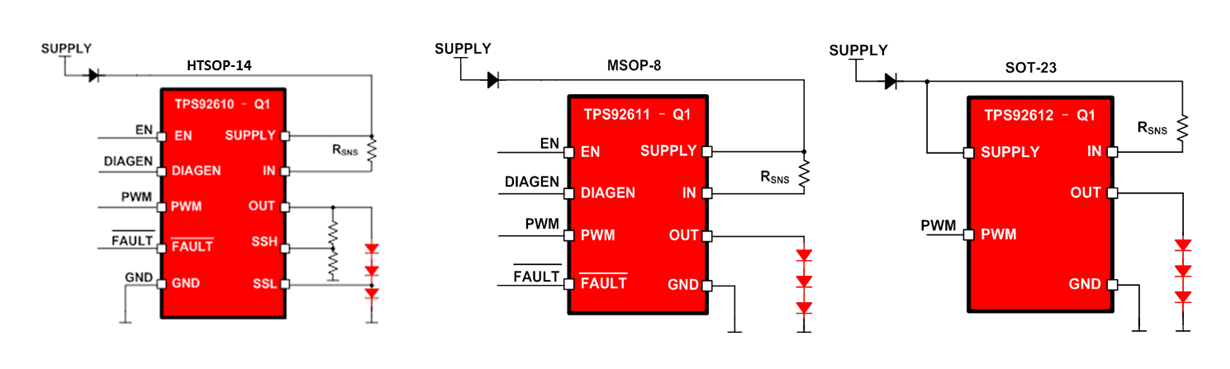

Every solution has its advantages and disadvantages, but compared to discrete solutions, a low-cost monolithic solution lowers system-level component counts and significantly improves current accuracy and reliability. The TPS9261x-Q1 family shown in Figure 2 is designed just for this purpose.

Figure 2 TPS9261x-Q1 Simplified

Circuit

Figure 2 TPS9261x-Q1 Simplified

CircuitThe TPS92610-Q1 device is a single-channel high-side LED driver operating from an automotive car battery. It is a simple and elegant solution to deliver constant current for a single LED string with full LED diagnostics. The accuracy is as high as 7%, which is adequate for most applications.

The TPS9261x-Q1 has different package options, from small outline transistor (SOT)-23, MSOP-8 up to thermally enhanced thin shrink small-outline package (HTSSOP)-14 to support different output power levels. With this family of single-channel automotive LED drivers, you can now say goodbye to discrete solutions.

Additional Resources:

- Read this blog post “Drive LEDs in virtual reality applications”

- Learn more about TI’s large LED driver portfolio.

- Check out the the body electronics and lighting portfolio here.