SSZT487 May 2019 MSP430FR2675 , MSP430FR2676

It only takes a quick walk through the appliance section at your local retailer to realize that simple home appliances like ovens and microwaves now have very complex user interfaces. Home appliance manufacturers have added innovative operating modes to better prepare a tasty dinner, but these features require many buttons to control them.

It’s not uncommon for a wall oven or microwave to have more than 25 buttons to control all of the functions built-in to the appliance, which can be daunting to consumers and requires many keystrokes to get things running.

Fortunately, touch wheels simplify complex user interfaces in microwaves and ovens. This article is the first in a four-part series, in which we’ll illustrate several methods that show how capacitive touch sensors address the challenges facing home appliance user interface designers.

Simplifying Common Interactions

The first step in making an appliance easier to use is reducing the number of steps to activate a common function. Entering a cooking time or setting a baking temperature can often require several steps, and many appliances use a numeric keypad for this task. What if it were possible to simplify the keystroke entry process down to a single touch-and-drag interaction?

Touch wheels detect the position of a finger around the perimeter of a circle by measuring variations in the capacitance of several sensing electrodes. Touch wheels are great for entering parameters, as the user needs only to touch anywhere on the wheel and drag their finger clockwise or counterclockwise to increase or decrease a value. The end result is the reduction of several keystrokes down to one expression.

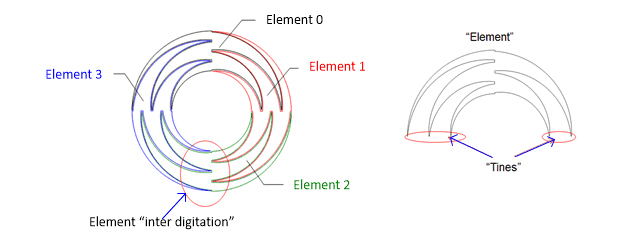

Figure 1 represents the pattern geometry for a typical touch wheel. There are 4 identical sensing elements, which may be implemented with copper regions on a printed circuit board. Elements are inter-digitated with “tines”. As a user moves clockwise or counterclockwise across the geometry, they reduce the surface area overlap between their finger and the current sensor and increase it between their finger and the next adjacent sensor. This variation in surface area leads to a measurable variation in the capacitance of the elements. Changes in capacitance across the elements of the touch wheel are resolved into a touched position by software.

Figure 1 Capacitive touch wheel

sensor

Figure 1 Capacitive touch wheel

sensor

Performance and Reliability

Microcontrollers (MCUs) such as the MSP430FR2676 are a good fit for implementing high-resolution touch wheels in appliances for these reasons:

- Parallel measurement of up to four electrodes eliminates the undesired effects of parasitic capacitance between electrodes in the wheel, enabling more accurate position tracking.

- Proven wheel-position algorithms are included in low-cost read-only memory to free up programmable memory.

- Positional resolution of as many as 10 bits is achievable.

If you’re worried about robustness to electrical noise, MSP430FR2675 and MSP430FR2676 MCUs have these capabilities to streamline your electromagnetic compatibility qualification:

- A frequency-hopping oscillator for immunity to conducted and radiated noise.

- Hardware-accelerated post processing to free up central processing unit resources.

- Simple configuration and tuning with TI’s CapTIvate™ Design Center tool.

Elevate your product today by leveraging capacitive touch sensing for the user interface, and consider collapsing the number of touch points with the use of a touch wheel.

Additional Resources

-

Evaluate what’s possible with slider and wheel sensors by purchasing the capacitive touch self-capacitance button, slider, wheel and proximity sensor demonstration board; the capacitive touch MSP430FR2676 MCU board; and the MSP430 CapTIvate MCU programmer.

-

Quickly and easily generate slider and wheel sensor patterns that fit the dimensions of your product using scripts available in TI’s application report, “Automating Capacitive Touch Slider and Wheel PCB Design Using OpenSCAD Scripts.”

-

Read the application report, “Capacitive Touch Gesture Software and Tuning.”