SSZT476 may 2019 TPS92610-Q1 , TPS92611-Q1 , TPS92612-Q1 , TPS92613-Q1

In automotive lighting such as turn lights, brake lights and tail lights, LED circuit designs typically implement discrete components like bipolar junction transistors (BJTs). Discrete components are prominent for a few common reasons: they’re simple, reliable and cheap. Yet as the number of LEDs and project requirements grows, it may be worth reconsidering designing discretely. Let’s explore some common misconceptions.

Discrete Designs Are Simple

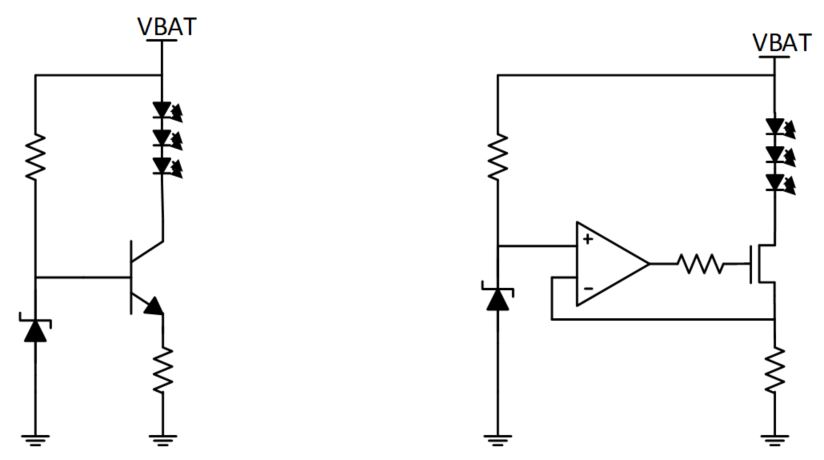

Figure 1 Constant-current Discrete LED Circuits

Figure 1 Constant-current Discrete LED CircuitsIn projects that have a high LED count or challenging requirements, the circuit design not only looks crowded but also requires complex analysis. Crowded with BJTs to drive multiple LEDs, a rear combination light (RCL) module may include the specifications listed in Table 1.

| Specification | Consideration | Implementation | |

|---|---|---|---|

| Function | Same set of LEDs for tail lights and stoplights | Adjust brightness levels to indicate mode | Analog current or pulse-width modulation (PWM) dimming |

| Battery supply | Nominal: 9 V to 16 V Range: 6 V to 40 V | Stable output current while withstanding voltage transients from start/stop, load dump, etc. | Constant current output circuit (see Figure 1) |

| Diagnostics | Open circuit | Detect fault and implement fault response | One-fail-all-fail (OFAF) circuitry |

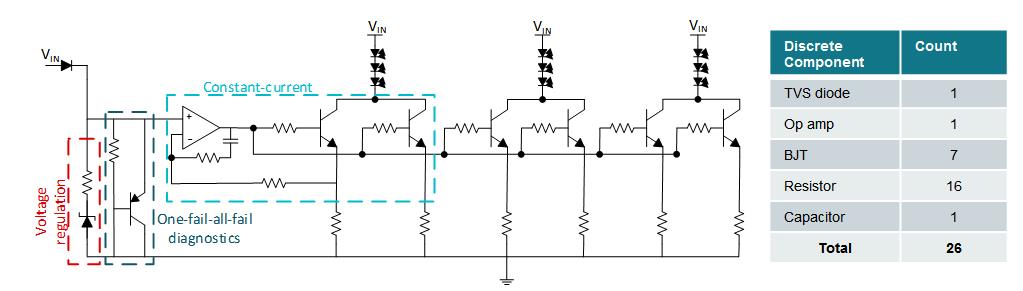

Using a high count of components like the RCL example in Figure 2 increases design and manufacturing risk, and you must carefully analyze the circuit.

Figure 2 Example Discrete Tail-light and Stoplight Circuit

Figure 2 Example Discrete Tail-light and Stoplight CircuitDiscrete Designs Are Reliable

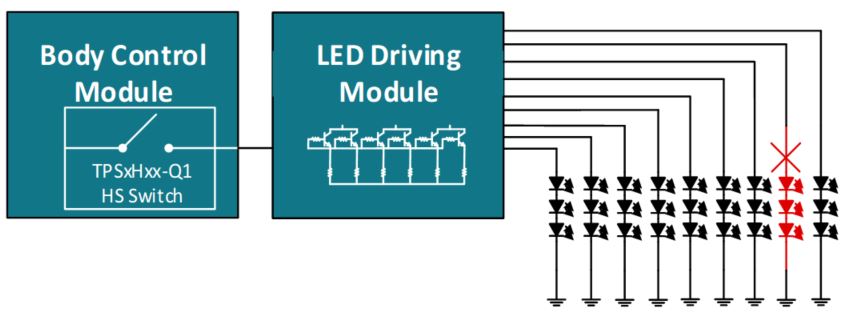

Feedback circuitry to diagnose LED open-circuit or short-circuit failures improves system reliability. While such circuitry adds more components, there are advantages. For example, if an LED breaks within a RCL, then the module’s brightness is no longer compliant with market regulations. The body control module (BCM) may have difficulty distinguishing between a valid LED load and a single open load from a lighting module, as shown in Figure 3. In the event of a broken LED, implementing OFAF circuitry will turn off all LEDs and make it easier to detect an open load. OFAF also prevents further LED degradation.

Figure 3 A BCM Diagnoses Faults from the LED Driving Module

Figure 3 A BCM Diagnoses Faults from the LED Driving ModuleThe LED circuit must meet emission and bulk current injection (BCI) immunity standards for electromagnetic compatibility (EMC). If you disregard EMC, the LED driving module could interfere with or be affected by other applications, creating a poor experience for drivers.

Discrete Designs Are Cheap

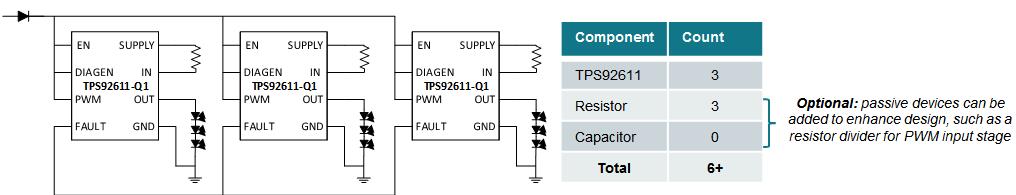

Figure 4 The TPS92611-Q1 with a Fault Bus Connected for OFAF

Figure 4 The TPS92611-Q1 with a Fault Bus Connected for OFAFIn addition to lowering component count and system costs, linear LED drivers deliver a constant-current output with a low dropout voltage, and adjustable brightness via analog current or PWM dimming. Thermal protection and short- and open-circuit diagnostics provide solid performance, and an OFAF fault bus can be connected across devices to ensure system reliability. The TPS92611-Q1 and other linear LED drivers also offer strong EMC performance compared to discrete solutions.

A LED driver IC solution is a cost-effective alternative to discrete circuits, especially in applications with high LED count or complex requirements. With simple designs, reliable performance and cost competiveness, put the brakes on discrete circuits and switch to an integrated linear LED driver today.

Additional Resources

- Read the white papers:

- Check out the CISPR 25 Class 5-compliant “Automotive dual stage (SEPIC + linear) static LED driver module reference design for rear lights.”

- Watch the TI Training video, “How to estimate junction temperature,” on thermal calculations for linear LED circuits.