SSZT404 october 2019 BQ25125 , BQ25155

From starting a car to powering a television remote, batteries provide the power that makes everyday objects possible. Yet not all batteries are made equal. Some are rated for lower temperatures, while others can provide higher peak-current discharge rates. Choosing the right battery can reduce an end product’s size, prolong its useful life and make it more robust.

When developing a new blood glucose monitor battery specification, your most critical decision will be whether the battery chemistry is disposable or rechargeable. Primary cells are typically cheaper, more energy dense and simpler to use – but also bulkier, wasteful and prone to leakage. Rechargeable cells are more customizable in their performance, have longer lifetimes, and enable a sleeker and more compact design.

Figure 1 Typical Disposable

Batteries

Figure 1 Typical Disposable

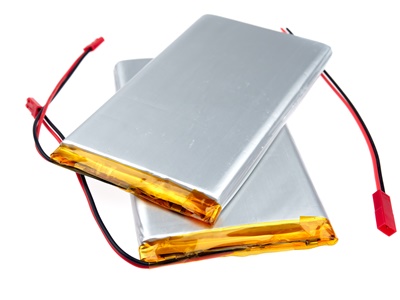

Batteries Figure 2 Typical Rechargeable

Battery

Figure 2 Typical Rechargeable

BatteryRechargeable batteries are also typically more expensive and complex to implement because of the additional components required for their operation. To many designers, these drawbacks mean that primary cells are the only choice for applications like blood glucose monitors. But rechargeable solutions add more value than just environmental benefits, even for simple and inexpensive devices.

To start, since it’s not possible to recharge primary-cell batteries, any device like a handheld monitor that uses them as a power source must factor in how much power is drained per hour of usage in order to determine the capacity needed for useful device run times. Consumers don’t like replacing the batteries on their devices daily or even weekly, so the capacity requirement must be many times the daily consumption.

To illustrate this fact, imagine that you’re designing a patch for monitoring posture at work. The device uses 50 mAh every eight hours at 4.2 V and has an intended 100 hours of use before replacement. To meet these performance targets with a primary cell, the capacity of the battery would have to be at least 625 mAh to provide enough power to the device. This unused capacity adds weight and size to a design that you could use elsewhere.

Meanwhile, a rechargeable battery would not need to last 100 hours; it only needs to power the worst case of use between charge cycles. If the device had 20 hours of use between rest periods, then you could design your system with a 125-mAh battery instead of the 625-mAh battery. Even though a primary-cell battery is three times as dense as its rechargeable alternative, this reduced capacity requirement more than compensates for the shortfall.

Another factor to consider with a primary-cell battery is battery content leakage, especially for alkaline-style batteries. As a battery is used, a chemical reaction occurs that can lead to an excess buildup of pressure within the cell. To cut costs, some primary-cell batteries are not made with the best venting or materials available. This leads to a structurally weak cell that over time can leak its contents onto sensitive electrodes, possibly damaging the affected device permanently. As a designer, why add another vector in which your device might fail?

Outside of the potential harm to the device, a primary-cell battery must be replaced semi-regularly. We have all had to change the battery in a remote after weeks of less-than-stellar signal strength. Once depleted, some primary cells require special disposal practices; all generate waste at higher rates than their rechargeable counterparts. As the world becomes more and more eco-conscious, you would be right to be concerned about the waste generated by millions of people replacing a battery every 100 hours vs. 2,000 hours of use, all because of your design choice.

Figure 3 Possible Waste Generated by

Primary Cells

Figure 3 Possible Waste Generated by

Primary CellsPrimary cells are at a steep disadvantage when dealing with growing energy consumption. Consumers like to be able to track their activity and other data through online applications. As things like Bluetooth® Low Energy and other communication standards are integrated into our everyday lives, energy demands increase and size decreases. Devices no longer sit idle when not in use but instead provide regular reports. This functionality expends energy, increasing the average energy per hour of use. Consumers will always want their devices to do more; rechargeable batteries enable that desire.

Chargers like the BQ25155 and the BQ25125 are small, simple to implement and powerful. With integrated low-dropout regulators, analog-to-digital and DC/DC converters, it is possible for these devices to be comprehensive battery-management units.

TI has a broad breadth of resources to guide you through the process of integrating a power-management system into your future designs, whether you’re an absolute novice or a power expert. From designs using 60-mAh batteries in your blood glucose monitors to the 5-Ah battery in your favorite power tool, we have a solution and support for any scenario.

Additional resources

- Discover TI’s battery charger solutions.

- Read the technical article,” Overcoming design challenges for low quiescent current in small, battery-powered devices.”

- Review the BQ25125 data sheet.