SSZT346 January 2020 LMR36503 , LMR36506 , TPS7A47 , TPSM265R1

As the factory automation and control equipment market evolves, shipments of equipment with sensors such as field transmitters, machine vision and position sensors are increasing. As a result, the demand for feature-rich power integrated circuits (ICs) that could power these devices is also growing.

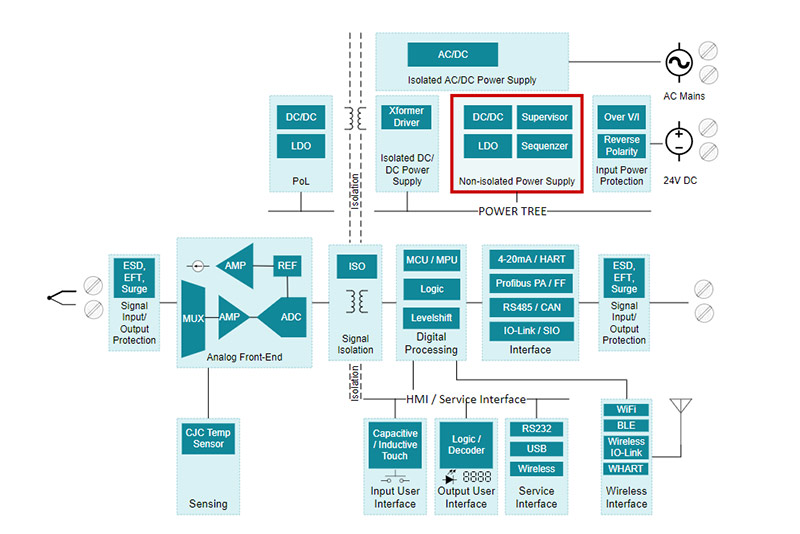

Figure 1 shows a block diagram of a temperature transmitter. The nonisolated power-supply subsystem (highlighted in red) consists of a low dropout regulator (LDO), a DC/DC converter or a power module. In an earlier technical article, “Powering tiny industrial automation control equipment with high-voltage modules: how to ensure reliability,” my colleague Akshay Mehta explained how to power miniature industrial automation control equipment with high-voltage modules. In this article, I’ll take a look at how to use buck converters and LDOs for the same purpose.

Figure 1 Temperature Transmitter

Subsystem

Figure 1 Temperature Transmitter

SubsystemHigh Input Voltage, Higher Stakes

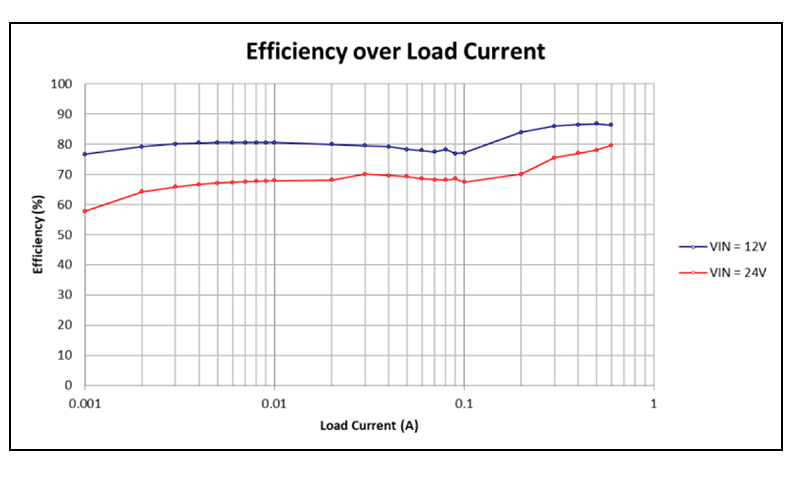

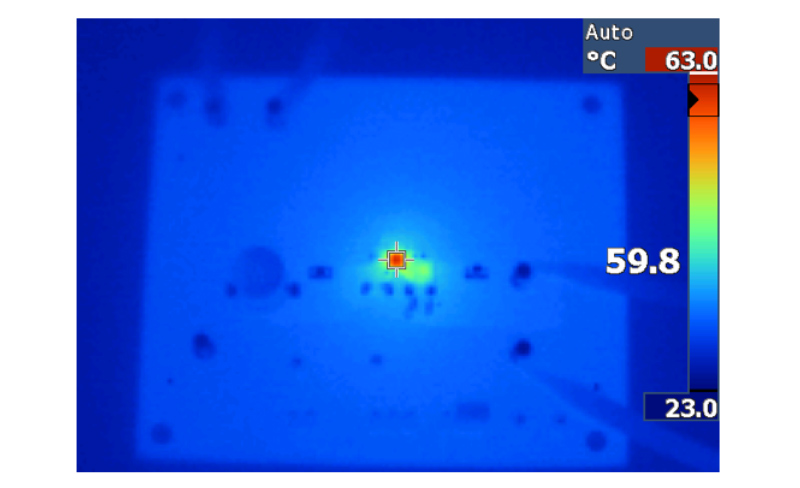

There are a number of ways to regulate the input DC voltage in factory automation and control equipment. You can use an LDO, a DC/DC converter or a power module. LDOs such as the TPS7A47 are commonly used in sensor power supplies due to their simple design and ability to attenuate input noise and deliver a ripple-free output voltage. DC/DC converters are a good choice for applications operating at lower output voltages, higher input voltages or higher output currents. For example, the LMR36503 and LMR36506 DC/DC converters enable a low shutdown current specification of 1 µA and an operating quiescent current specification of 7 µA. For loads with low output currents – less than 20 mA – these performance specifications ensure higher efficiency for 4- to 20-mA loop applications. Figure 2 shows the efficiency and thermal performance of the LMR36506 converter.

Figure 2 Efficiency and Thermal

Performance at 24 vIN, 5 VOUT, 2.1 Mhz at 0.6A

Figure 2 Efficiency and Thermal

Performance at 24 vIN, 5 VOUT, 2.1 Mhz at 0.6ABig Challenge, Small Solution

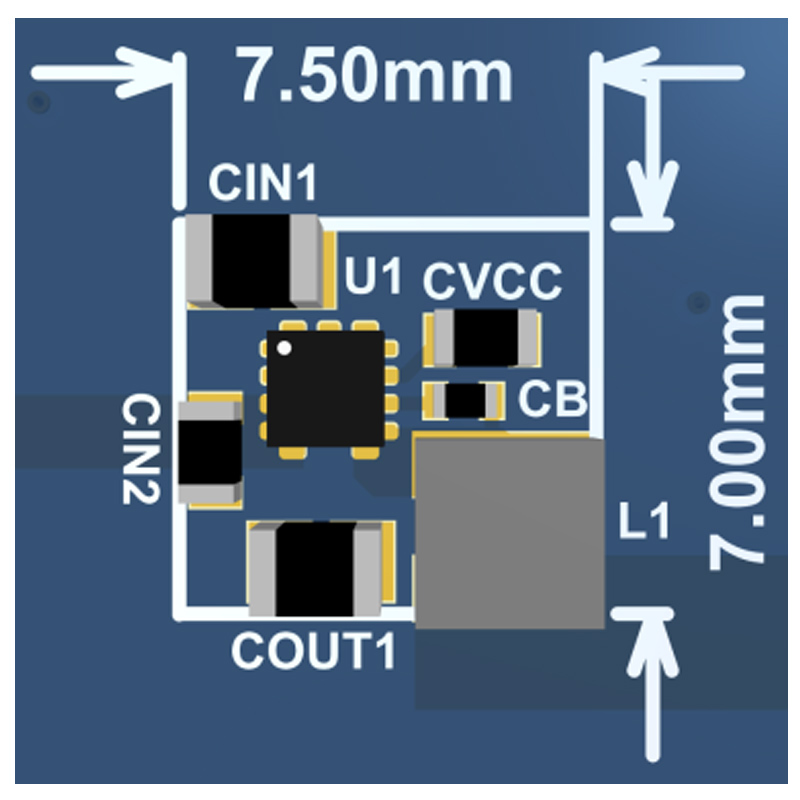

TPSM265R1 LMR36503 LMR36506 IN OUT Figure 3 LMR36506 Example Solution

Size

Figure 3 LMR36506 Example Solution

SizeLowering EMI, Raising the Standard

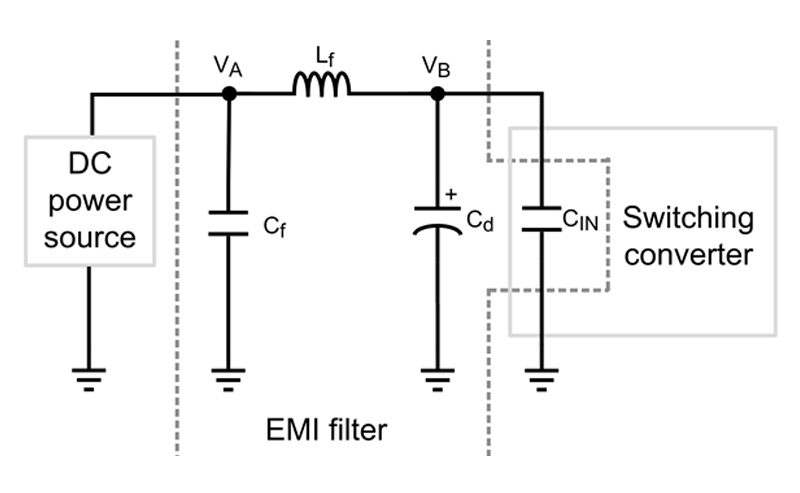

Figure 4 An EMI Filter Structure for

DC/DC Converters

Figure 4 An EMI Filter Structure for

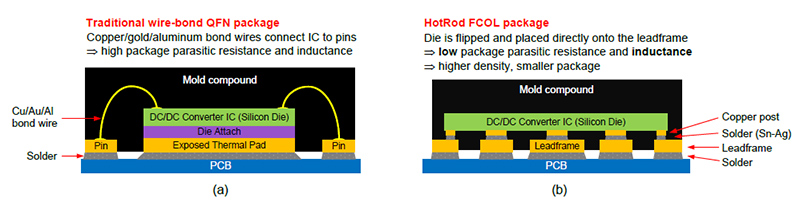

DC/DC Converters Figure 5 Wire-bond Quad Flat No-lead

and FCOL Packages

Figure 5 Wire-bond Quad Flat No-lead

and FCOL PackagesConclusion

LMR36506Additional Resources:

- If you’re considering using modules to power your solution, read our technical article: Powering tiny industrial automation control equipment with high-voltage modules: how to ensure reliability