SSZT207 December 2020 ISO7741-Q1 , LMG3425R030 , TMS320F2800137 , TMS320F280025C , TMS320F280039C , TMS320F28379D

Gallium nitride (GaN) field-effect transistors (FETs) provide drastically improved switching losses and higher power density over silicon-carbide and silicon-based FETs, respectively. These traits can be particularly helpful in high-switching-frequency applications such as digital power converters, where they can help reduce the size of the magnetics.

Designers in the power electronics industry need new technologies and methods to increase performance in GaN systems. C2000™ real-time microcontrollers (MCUs) can help address design challenges when developing modern power-conversion systems using GaN technology.

The benefits of C2000 real-time MCUs

- Complex, time-critical calculation processing. C2000 MCUs have an advanced instruction set that drastically reduces the number of cycles required for complex math calculations. This reduction in calculation time makes it possible to increase the control-loop frequency without increasing the MCU’s operating frequency.

- Precise control. The high-resolution pulse-width modulator (PWM) in a C2000 MCU enables 150-ps resolution, while built-in analog comparators and a configurable logic block help safely handle error conditions.

- Software and peripheral scalability. As system requirements change, the C2000 platform enables the scaling of real-time MCU features up or down while maintaining software investments to achieve faster time to market. A low-cost C2000 MCU such as the TMS320F280025C, for example, enables real-time processing and control in a small-server power supply while maintaining code compatibility with the TMS320F28379D, which is a popular device in higher frequency multiphase systems.

Addressing GaN switching challenges with C2000 MCUs

Interfacing C2000 MCUs with TI GaN technology

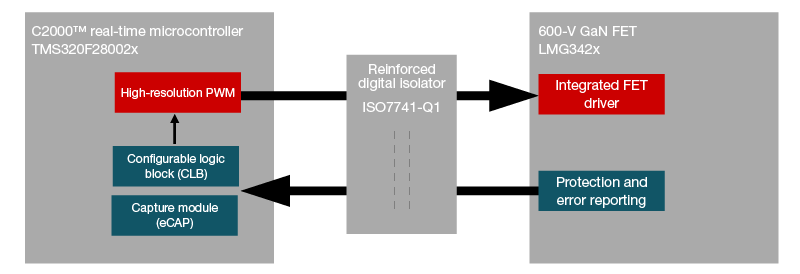

Figure 1 Interfacing a C2000 MCU, digital isolator and 600-V GaN FET

Figure 1 Interfacing a C2000 MCU, digital isolator and 600-V GaN FETA reinforced digital isolator helps suppress transient noise and protects the C2000 MCU. The C2000 MCU provides precise control output using its high-resolution PWM and configurable logic block and enhanced-capture modules to capture all of the GaN FET’s safety, temperature and error-reporting features without the use of external glue logic. The integrated driver in a 600-V GaN FET reduces system design concerns caused by inductive ringing. Combining these devices eliminates the need for external components, reducing overall costs.

Learn more about the advanced features of TI’s GaN FETs in the technical article, “How GaN FETs with integrated drivers and self-protection will enable the next generation of industrial power designs.”

Conclusion

Additional resources

- Read the white paper, Achieve Power-Dense and Efficient Digital Power Systems by Combining TI GaN FETs and C2000 Real-Time MCUs

- Check out these reference design, Bidirectional High-Density GaN CCM Totem Pole PFC Using C2000 MCU.

- Read the application report, “Does GaN Have a Body Diode? – Understanding the Third Quadrant Operation of GaN.”

- Learn more about the capabilities of the configurable logic block in the TI training, “C2000 Configurable Logic Block (CLB) Introduction.”

- Read the technical article, "Meeting 3 server power supply design trends with a real-time MCU" and learn about the F28003x MCU family.