SSZT153 june 2021 TLV840 , TLV841

Within the last decade, manufacturers of wearable technologies such as smartwatches have made significant advancements in enabling users to track their personal health and fitness in real time. It’s now possible to leverage a wealth of statistics, such as step count, heart rate, oxygen saturation, workout duration and more, and track progress toward fitness goals in a variety of ways.

As smartwatches become indispensable, battery longevity and small form factor are essential consumer considerations, encouraging device manufacturers to continuously reduce the power consumption and product footprint – and causing all sorts of headaches for power-supply designers. Adding voltage supervisors to your next wearable design can help – and here are three reasons why.

No. 1: Voltage Supervisors Can Help Improve the Reliability of Your Design

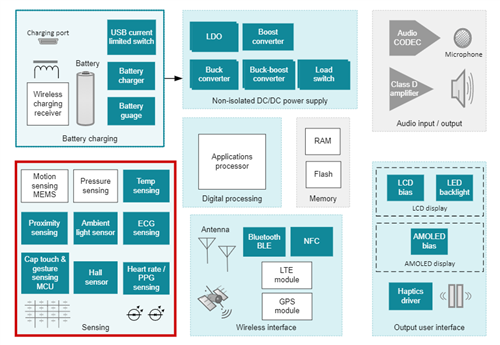

Figure 1 is a system block diagram of a smartwatch. The processor comes with multiple voltage rails that need undervoltage monitoring, which is vital to system stability.

Figure 1 Smartwatch Block Diagram

Figure 1 Smartwatch Block DiagramA voltage lower than the required minimum can lead to an unexpected overwrite to onboard memory, a system freeze or data corruption. Designers usually implement a resistor-capacitor (RC) charging circuit to prevent these types of processor errors and delay the reset signal.

Although the implementation is simple, a RC circuit has its limitations: the reset delay is unpredictable depending on input voltage conditions such as slew rate and low operating voltage. A RC circuit also lacks undervoltage monitoring.

Modern voltage supervisors such as the TLV841 offer a better solution – not only can they monitor for undervoltage conditions, they also offer precise delay time capabilities to ensure that the voltage rails are within operating ranges, thus enhancing system reliability, dependability and functionality.

No. 2: Voltage Supervisors Can Help Improve Design Accuracy

Today’s microprocessors need very accurate voltage monitoring. Voltage supervisors provide an increased level of precision to address any issues resulting from the low accuracy of an integrated power good signal that usually comes from a DC/DC regulator. In addition, they offer low quiescent current (IQ) consumption. For instance, the TLV841 consumes only 125 nA. By combining low IQ with the ability to accurately monitor a supply voltage at 0.5%, modern voltage supervisors give you the confidence to design accurate systems without affecting battery life.

No. 3: Voltage Supervisors Can Help You Miniaturize Your Design

An analog watch has a diameter of 38 mm to 44 mm. With limited space and the need to design several circuits to support advanced features such as a GPS module, heart rate sensors, a step counter and touch sensors, keeping the design small can be a real challenge, especially since each of the subsystems has its own required voltage rail. Manufacturers often make compromises between product features and while keeping the device size to a minimum.

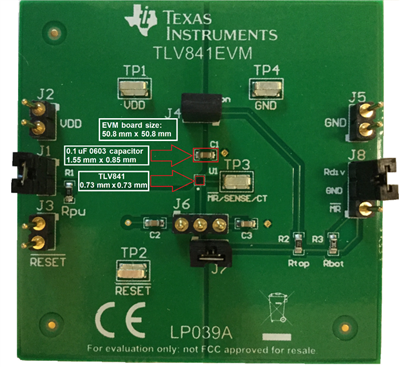

Modern voltage references are available in a wafer chip-scale package, where the size of the package equals the size of the die. The TLV841 has a tiny form factor (0.73 mm by 0.73 mm) and is available in a common pitch of 0.4 mm, with a height of 0.4 mm. Adding voltage supervisors of this size to a design is crucial to a fitness watch’s operational reliability and functionality.

Figure 2 illustrates the comparison between the size of TLV841 and a commonly sized 0603 component, such as a 0.1 μF capacitor.

Figure 2 TLV841 Evaluation Board

Figure 2 TLV841 Evaluation BoardConclusion

As consumer demands push smartwatches to their limits in regard to physical dimensions, battery life and system performance, meeting corresponding design requirements is a priority. Modern voltage supervisors open up new application opportunities, allowing you to integrate more features into your wearable device designs while improving overall system stability and reliability, and without affecting product size.

Additional Resources

- Read these technical articles:

- Read the white paper, “Overcoming Low-IQ Challenges in Low-Power Applications.”