SLVSBV4B April 2013 – October 2015 TPS56428

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Detailed Description

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

封装选项

机械数据 (封装 | 引脚)

散热焊盘机械数据 (封装 | 引脚)

- DDA|8

订购信息

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

9.1 Application Information

The TPS56428 is typically used as a step down converter, which convert a voltage from 4.5V–18V to a lower voltage. WEBENCH software is available to aid in the design and analysis of circuits.

9.2 Typical Application

Figure 8. Schematic Diagram for This Design Example.

Figure 8. Schematic Diagram for This Design Example.

9.2.1 Design Requirements

To begin the design process, you must know a few application parameters:

- Input voltage range

- Output voltage

- Output current

- Output voltage ripple

- Input voltage ripple

9.2.2 Detailed Design Procedure

Output Voltage Resistors Selection

The output voltage is set with a resistor divider from the output node to the VFB pin. It is recommended to use 1% tolerance or better divider resistors. Start by using Equation 2 to calculate VOUT.

To improve efficiency at very light loads consider using larger value resistors, too high of resistance will be more susceptible to noise and voltage errors from the VFB input current will be more noticeable.

9.2.2.1 Output Filter Selection

The output filter used with the TPS56428 is an LC circuit. This LC filter has double pole at:

At low frequencies, the overall loop gain is set by the output set-point resistor divider network and the internal gain of the TPS56428. The low frequency phase is 180 degrees. At the output filter pole frequency, the gain rolls off at a –40 dB per decade rate and the phase drops rapidly. D-CAP2™ introduces a high frequency zero that reduces the gain roll off to –20 dB per decade and increases the phase to 90 degrees one decade above the zero frequency. The inductor and capacitor selected for the output filter must be selected so that the double pole of is located below the high frequency zero but close enough that the phase boost provided be the high frequency zero provides adequate phase margin for a stable circuit. To meet this requirement use the values recommended in Table 1.

Table 1. Recommended Component Values

| Output Voltage (V) |

R1 (kΩ) | R2 (kΩ) | C4 (pF)(1) | L1 (µH) | C7 + C8 (µF) | ||||

|---|---|---|---|---|---|---|---|---|---|

| MIN | TYP | MAX | MIN | TYP | MAX | ||||

| 1 | 33.2 | 49.9 | 5 | 33 | 100 | 1.0 | 1.5 | 4.7 | 20 - 68 |

| 1.05 | 37.4 | 49.9 | 5 | 33 | 100 | 1.0 | 1.5 | 4.7 | 20 - 68 |

| 1.2 | 49.9 | 49.9 | 5 | 22 | 47 | 1.0 | 1.5 | 4.7 | 20 - 68 |

| 1.5 | 75.0 | 49.9 | 5 | 15 | 33 | 1.0 | 1.5 | 4.7 | 20 - 68 |

| 1.8 | 100 | 49.9 | 5 | 10 | 22 | 1.0 | 1.5 | 4.7 | 20 - 68 |

| 2.5 | 158 | 49.9 | 5 | 10 | 22 | 1.5 | 2.2 | 4.7 | 20 - 68 |

| 3.3 | 226 | 49.9 | 2 | 5 | 15 | 1.5 | 2.2 | 4.7 | 20 - 68 |

| 5 | 365 | 49.9 | 2 | 5 | 10 | 2.2 | 3.3 | 4.7 | 20 - 68 |

| 6.5 | 487 | 49.9 | 2 | 2 | 10 | 2.2 | 3.3 | 4.7 | 20 - 68 |

For higher output voltages at or above 1.8 V, additional phase boost can be achieved by adding a feed forward capacitor (C4) in parallel with R1

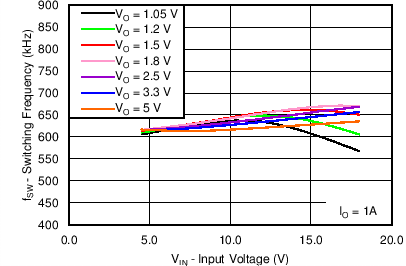

The inductor peak-to-peak ripple current, peak current and RMS current are calculated using Equation 4, Equation 5 and Equation 6. The inductor saturation current rating must be greater than the calculated peak current and the RMS or heating current rating must be greater than the calculated RMS current. Use 650 kHz for fSW.

Use 650 kHz for fSW. Make sure the chosen inductor is rated for the peak current of Equation 5 and the RMS current of Equation 6.

For this design example, the calculated peak current is 4.51 A and the calculated RMS current is 4.01 A. The inductor used is a TDK SPM6530-1R5M100 with a peak current rating of 11.5 A and an RMS current rating of 11 A.

The capacitor value and ESR determines the amount of output voltage ripple. The TPS56428 is intended for use with ceramic or other low ESR capacitors. Recommended values range from 20µF to 68µF. Use Equation 7 to determine the required RMS current rating for the output capacitor.

For this design two TDK C3216X5R0J226M 22µF output capacitors are used. The typical ESR is 2 mΩ each. The calculated RMS current is 0.284A and each output capacitor is rated for 4A.

9.2.2.2 Input Capacitor Selection

The TPS56428 requires an input decoupling capacitor and a bulk capacitor is needed depending on the application. A ceramic capacitor over 10µF is recommended for the decoupling capacitor. An additional 0.1 µF capacitor from pin 8 to ground is optional to provide additional frequency filtering. The capacitor voltage rating needs to be greater than the maximum input voltage.

9.2.2.3 Bootstrap Capacitor Selection

A 0.1µF ceramic capacitor must be connected between the VBST to SW pin for proper operation. It is recommended to use a ceramic capacitor.

9.2.2.4 VREG5 Capacitor Selection

A 0.47-µF ceramic capacitor must be connected between the VREG5 to GND pin for proper operation. It is recommended to use a ceramic capacitor

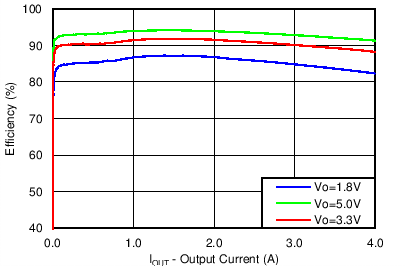

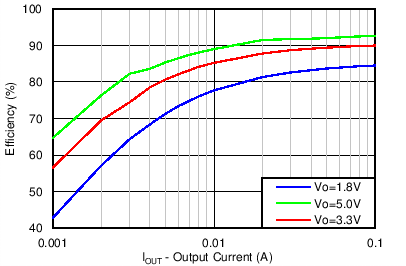

9.2.3 Application Curves

VIN = 12 V, TA = 25°C (unless otherwise noted) Figure 9. 1.05 V Load Transient Response

Figure 9. 1.05 V Load Transient Response

Figure 11. Efficiency vs Output Current

Figure 11. Efficiency vs Output Current

Figure 10. Slow Start

Figure 10. Slow Start

Figure 12. Efficiency vs Output Current

Figure 12. Efficiency vs Output Current