SSZT083A April 2022 – May 2024

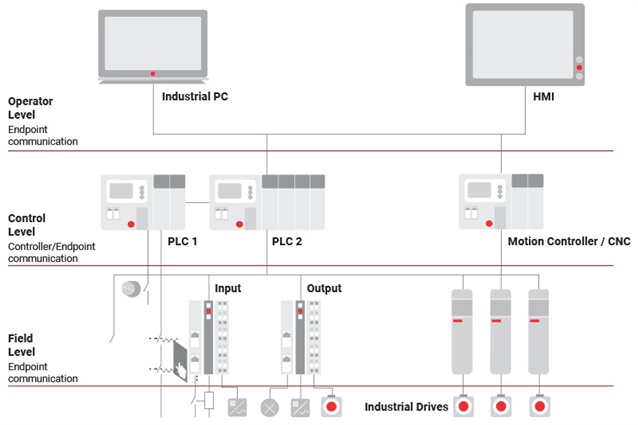

A typical factory automation environment has multiple levels of operator and field control to establish device-to-device communication. As smart factories become more prevalent, it’s a challenge to design systems that not only address the complex computational needs of larger data sets throughout the factory, but to do so in a way that addresses multiprotocol real-time communication, as shown in Figure 1, with readiness for future system management and upgrades.

Figure 1 Factory Automation Platforms

Often Have Multiple Communication Endpoints Requiring Different Industrial

Protocols

Figure 1 Factory Automation Platforms

Often Have Multiple Communication Endpoints Requiring Different Industrial

ProtocolsTo truly address the evolving demands of smart factories, modern processors must address the challenges of computational demands for real-time control, safety and reliability, as well as the flexibility of multiprotocol communication, in a scalable design for future solutions.

Enabling Real-time Control for Edge Computing

Edge computing localizes data computation close to the point of origin in order to achieve efficient data processing for both local and cloud-based systems. For factory automation, edge computing achieves real-time control by enabling low-latency computation and communication at the data source. In a robot arm, for example, multiple motors are controlled locally, while a central programmable logic controller (PLC) controls the whole arm.

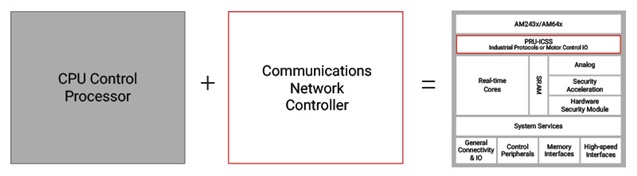

Addressing computation and communication challenges traditionally required multichip solutions, sometimes including a networking chip for high-speed industrial communication as well as a processor for data computation. By combining the processing capability for real-time edge computing with a pre-certified integrated multiprotocol industrial stack, TI’s Sitara™ AM64 microprocessor unit (MPU) family and the AM243 microcontroller (MCU) family simplify the development process for real-time industrial communication and control.

The AM64 MPU and AM243 MCU families of devices are each able to manage industrial communication with a programmable real-time unit industrial communication subsystem (PRU-ICSS), a co-processor subsystem containing PRU cores and Ethernet media access controllers. This structure enables the management of low-level Industrial Ethernet and field-bus protocols through firmware, making AM64 MPU and AM243 MCU application cores available to process – in parallel – both communication and data computation for low-latency, real-time control and communication at the edge.

Figure 2 The PRU-ICSS in Both the AM64 MPU and AM243 MCU Families Provides a Single-chip Solution for Real-time Control and Communications

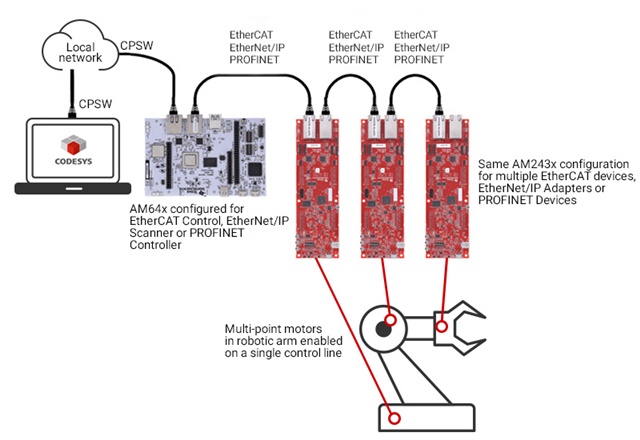

Figure 2 The PRU-ICSS in Both the AM64 MPU and AM243 MCU Families Provides a Single-chip Solution for Real-time Control and CommunicationsIt is possible to configure the AM243 MCU family for real-time control of multiple motors in a robot arm, sensing position or speed at the point of feedback. The data from this feedback then passes to a central unit, where the AM64 MPU family computes multiple input data streams for higher-level PLC control. To manage real-time control with multipoint data-sharing scenarios such as these, processors require low latency, low jitter and multicore parallel processing capability. The AM64 and AM243 families can connect tens or even hundreds of devices with only one cable and port at the controller, and still meet cycle times ≤ 11 ms for real-time control. The AM64 and AM243 families’ scalable hardware and software solutions, shown in Figure 3, offers the ability to choose from multiple protocol options using the TI-certified stack available in each device’s respective software development kit (SDK), meaning either can be used to achieve integrated industrial protocol solutions with a single chip.

Figure 3 Choose from Multiple Protocol Options with the AM64 and AM243 Families

Figure 3 Choose from Multiple Protocol Options with the AM64 and AM243 FamiliesImplementing Multiple Industrial Protocols

Implementing edge computing for a multisystem design includes having to manage multiple communication protocols. While each subsystem on a factory floor may need to communicate information to a central control unit individually, they often operate on different industrial communication protocols. Truly achieving real-time control and communication in a single chip requires the integration of a multiprotocol programmable software solution so that you can select the best protocol for your design and scale easily for reuse. TI’s AM64 MPU and AM243 MCU families SDKs enable you to connect to multiple industrial protocols including Ethernet, Profibus or IO-Link for easy reuse across multiple device interfaces.

Integrated industrial protocols from TI are an optional feature in both the Sitara AM64x and AM243x A53 Arm® core processor families, designed to simplify communication with a pre-certified multiprotocol stack for the Industrial Ethernet protocol and IO-Link standard. You can choose from three stack types for industrial protocol development:

- Fully licensed integrated stacks from TI.

- Third-party protocol stacks.

- Your own custom stack.

Table 1 summarizes the supported protocols and minimum timing at a high level, with a detailed feature set for each protocol available in the industrial communications tool kit within the SDKs for AM64x Sitara processors and AM243x Sitara MCUs.

| Protocol | Min. cycle time | Conformance test/certification | Key features supported |

|---|---|---|---|

| EtherCAT® | 31.25 us | ETG.7000.2 | CiA402, CAN over EtherCAT (CoE), Servo Drive Profile (SoE), Ethernet over EtherCAT (EoE), File Access over EtherCAT (FoE), Distributed Clocks |

| EtherNet/IP™ | 1 ms | CT18.1 | Address COnflict Detection (ACD), Quality of Service (QoS), Device Level Ring (DLR), Precision Time Protocol (PTP) |

| PROFINET® | 250 us (IRT) 1 ms (RT) | 2.4.2 | Conformance Class A, B (RT), and C (IRT), Precision Time Control Protocol (PTCP), Media Redundancy Protocol (MRP) |

| IO-Link® | All communication classes supported | 1.1.2 | Up to 8 channel IO-Link Master per ICSS, IO-Link standard-compliant with Standardized Master Interface (SMI) |

The integrated multiprotocol stack provides licensed protocol software in a TI-supported firmware solution to reduce cost and development time and is accessible through the SDKs, which use a common application programming interface to facilitate multiprotocol use from a single platform. Integrated protocols enable a single-chip solution for industrial communication and control by using one of the quad R5 cores for real-time communication; offloading application cores to enable parallel processing to support control functions; and including the industrial Ethernet protocol and IO-Link standard for a comprehensive industrial communication platform. It’s also possible to use the separate application core from Codesys Control operating on both an AM64processor and an AM243 MCU connected to an endpoint device, such as an input/output controller. The flexibility of this solution lets you change the industrial protocol from EtherNet/IP™ to PROFINET® or to EtherCAT® without modifying any hardware.

Managing for System Upgrades and Scalability

As smart factories and Industry 4.0 continue to develop, design engineers will continue facing the challenge of developing evolving solutions for real-time control. Scalable hardware and software from the TI Sitara™ processor portfolio and integrated industrial protocols available in the AM243x MCU and AM64x processor families help to simplify real-time control and communication design.

Additional Resources

- Check out the full training from the Sitara MCU+ Academy for getting started with EtherCAT, EtherNet/IP, and PROFINET for the AM243 MCU family.

- Download the application note, "Industrial Communication Protocols Supported on Sitara Processors and MCUs."

- Watch these TI training videos: