SLUS846C September 2008 – June 2015 UCC25600

PRODUCTION DATA.

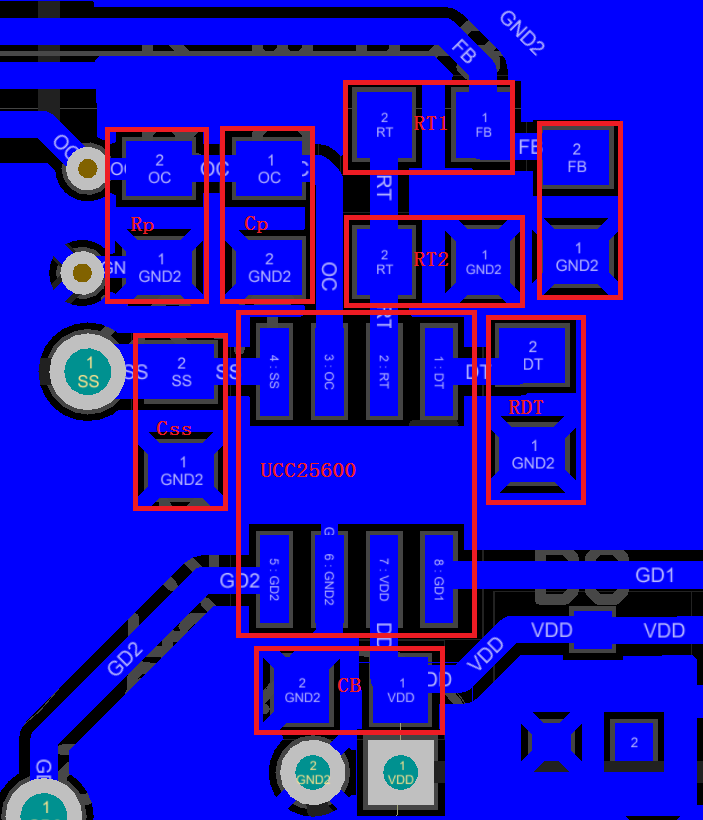

10 Layout

10.1 Layout Guidelines

Four-layer layout is recommended

A 1-µF ceramic decoupling capacitor is recommended, to be placed as close as possible between the VCC terminal and GND, and tracked directly to both terminals.

Place CSS, RDT, Rp, Cp, RT1, and RT2 as close as possible to the UCC25600.

Connect a regulated bias supply to the VCC pin.

10.2 Layout Example

Figure 27. Board Layout Example

Figure 27. Board Layout Example